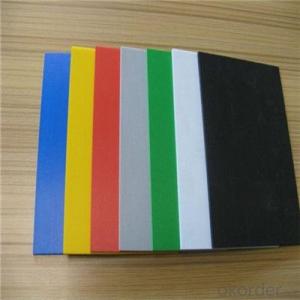

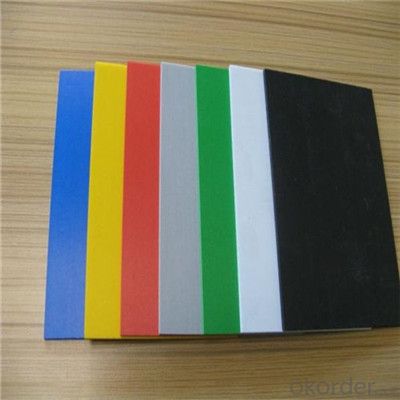

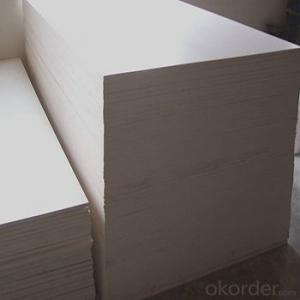

Plastic Sheets - PVC Foam Sheet Sandwich Board Hard Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

We are specialized in manufacturing PVC foam board.

Standard Size We Provide as below:

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

4.FAQ

1. If the products have some quality problem ,how will you deal with it?

Answer : If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

5.pictures

- Q: Last month, I covered my allotment with black plasting sheeting to suppress weeds, how long before weeds/grass is gead I can start digging?

- Personally, I only use plastic to keep down weeds during the growing season and cut cross slits to plant through. Instead, I remove the top 2 to 3 inches of soil and discard them (well chopped) in the compost. Then I add soil amendments such as a cheap fertilizer called Milorganite, Bone meal, Sugar, Epsom salt and cream of tartar (a form of Potassium).

- Q: What are the different thickness options for plastic sheets?

- The thickness options for plastic sheets can vary depending on the specific type of plastic being used. However, common thickness options for plastic sheets range from as thin as 0.010 inches (0.25 mm) to as thick as 0.500 inches (12.7 mm) or even more.

- Q: Are plastic sheets resistant to scratching from tools?

- Plastic sheets can vary in their scratch resistance depending on the type and quality of plastic used. Some plastic sheets, such as those made from polycarbonate or acrylic, are designed to be more resistant to scratching and can withstand light to moderate contact with tools. However, it is important to note that no plastic is completely scratch-proof, and heavy or sharp tools can still potentially cause damage.

- Q: Are plastic sheets resistant to cracking from flexing?

- Yes, plastic sheets are generally resistant to cracking from flexing due to their flexibility and elasticity. However, the resistance can vary depending on the type and quality of plastic used.

- Q: Iam doing a project with painters sheeting plastic which needs to be bond together without unlocking.I do not know which quick drying glue to use.Can anyone tell me which glue is the right glue for my project? (preferably quick drying glue ) Thanks,and HAPPY HOLIDAY.....HO,HO,HO,HO,HO.

- I would recommend using duct tape instead. Most glues aren't going to stick very well to the plastic as it is polyethylene and is difficult to bond too. It is possible to heatseal the too pieces together.

- Q: Do plastic sheets have UV protection?

- Yes, plastic sheets can have UV protection. Many plastic sheets are made with additives that help block or absorb ultraviolet (UV) rays, providing protection against sun damage and fading.

- Q: I have a Brother HL-5140 and I've search the internet, but cannot find out if this printer will print on the overhead projection paper or if it will melt the plastic sheets. Can anyone with this printer tell me? Or can someone tell me what wording to look for on a list of printer specs that will tell me? Thanks!

- This Site Might Help You. RE: Can my printer print on overhead projection sheets? I have a Brother HL-5140 and I've search the internet, but cannot find out if this printer will print on the overhead projection paper or if it will melt the plastic sheets. Can anyone with this printer tell me? Or can someone tell me what wording to look for on a list of printer...

- Q: Can plastic sheets be used for vacuum packaging?

- Yes, plastic sheets can be used for vacuum packaging.

- Q: I think the cheese slices that are not placed in these individual plastic sheets tastes better. Why do they do this?

- Kraft makes two different kinds of cheese slices - actual real cheese (not wrapped) and fake cheese (wrapped). The fake ones have to be wrapped to keep their shape during packaging and travel to the supermarkets, as it is basically just milk and a bunch of chemicals, so they have to be kept together to stay in the square shape. The other ones taste better because they are real cheese (or at least partially real cheese).

- Q: Can plastic sheets be used for wall cladding?

- Yes, plastic sheets can be used for wall cladding. They are a durable and cost-effective option, offering protection against moisture and providing insulation. Additionally, plastic sheets come in a variety of colors and designs, allowing for aesthetic customization.

Send your message to us

Plastic Sheets - PVC Foam Sheet Sandwich Board Hard Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords