Plastic Sheets - PVC Foam Sheet for Furniture Wall Almiraah Designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

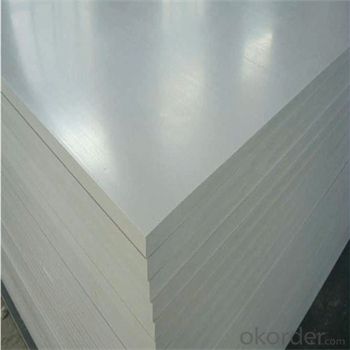

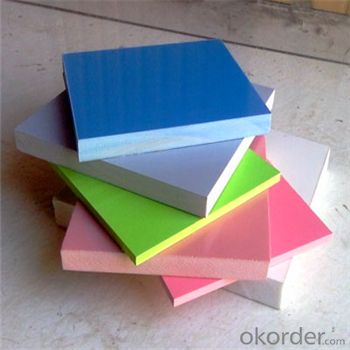

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

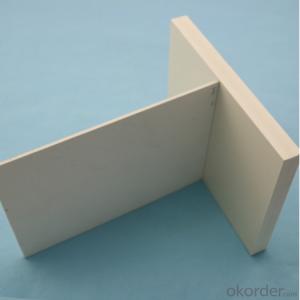

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Hardness:≥10Mpa

3. Product Features

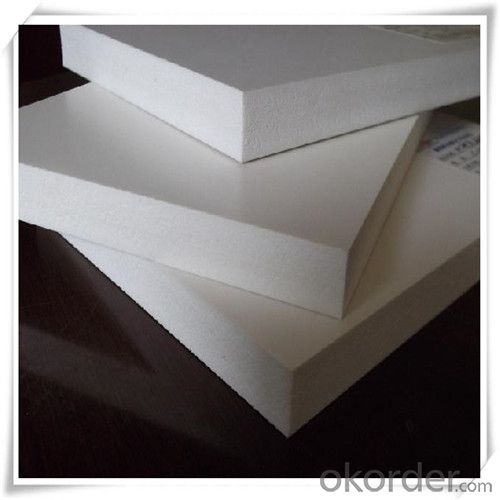

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5. Product Picture

6.FAQ

Q:We can get the free sample?

A:Of course.

- Q: Do you have to use special ink or a special printer to print sheets for an overhead projector?

- There is no need for a special printer or ink. I belive that you can print directly on the clear lexan sheets as though they were paper. I would be careful, though. Logic dictates that the ink may be fragile when printed on such a surface.

- Q: suggest two ways of converting transparent plastic sheet into translucent sheet

- Transparent Plastic Sheet

- Q: What is the weight of plastic sheets?

- The weight of plastic sheets can vary depending on their size, thickness, and material composition.

- Q: where can i buy like glass or plastic sheets/ walls in different sizes? Does home depot sell them? and how much are they?

- acrylic okorder ...

- Q: I just bought a few packages of sheets for the bed and I wanted to find some uses for those clear zippered bags that the sheets come in. What are some good uses for those?

- I use them for storing sheets out of season. And recently I found one that fits my waffle iron perfectly. I don't use the waffle iron much so it would collect a lot of dust if it wasn't covered.

- Q: Are plastic sheets resistant to chemicals used in industrial processes?

- Yes, plastic sheets are generally resistant to the chemicals used in industrial processes. They are designed to withstand a wide range of chemicals, making them a suitable choice for various industrial applications.

- Q: How do plastic sheets handle static electricity?

- Plastic sheets, being insulators, tend to accumulate static electricity rather than conducting it. This means that they can build up a charge when in contact with other materials or through friction. However, their ability to dissipate or discharge this static charge is generally low.

- Q: Are plastic sheets resistant to impact from hail or debris?

- Yes, plastic sheets are generally resistant to impact from hail or debris due to their durable and flexible nature. However, the level of resistance may vary depending on the thickness and quality of the plastic used.

- Q: Are plastic sheets resistant to abrasion?

- Yes, plastic sheets are generally resistant to abrasion.

- Q: Are plastic sheets resistant to discoloration from food stains?

- Yes, plastic sheets are generally resistant to discoloration from food stains.

Send your message to us

Plastic Sheets - PVC Foam Sheet for Furniture Wall Almiraah Designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords