Plastic Sheets PVC Foam Board for Wall Cladding/Decorating - Best Selling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About us:

We are packaging foam board manufacturer, packaging foam board is becoming the substitution of wood in many fields such as AD and Decoration. We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer. It made through foaming and pressing into shape with additives. The main material is PVC. So it covers not only features of woodplast, but also very light and can be printed, engraved easily.

Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

Features:

1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

Product Features:

(1) Light weight, waterproof, fire retardant and self-extinguishing .

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long.

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

The Advantages:

Our products are exported to North America, South America, Europe, the middle-south Asia, the Middle East, etc., and have good market in these places. The global spread of overseas warehouse for our shipment to the nearest

FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Q: How to get the price?

A: Please tell me the following information and I'll send you the quotation without delay:

color (white,black,grey,red,blue or other)

thickness (1mm~30mm)

size (1220x2440mm standard,customized is available)

density (0.35-0.80)

quantity(affecting the delivery time

Low Price Excellent chemical and corrosion resistance 3mm pvc foam board.

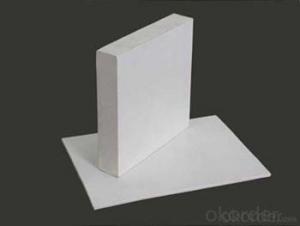

Product pictures

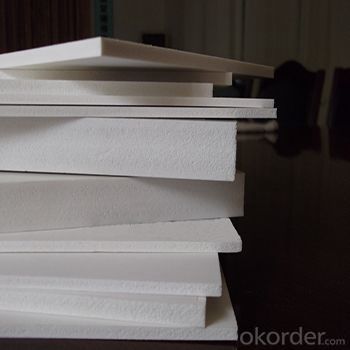

Packing picture

- Q: Can plastic sheets be used for shelving?

- Yes, plastic sheets can be used for shelving. They are lightweight, durable, and easy to clean, making them a practical choice for organizing and storing items on shelves.

- Q: where do they sell Corrugated Plastic sheets?

- Home okorder /

- Q: How do plastic sheets compare to PVC sheets?

- Plastic sheets and PVC sheets are essentially the same thing. PVC stands for polyvinyl chloride, which is a type of plastic. So, there is no significant difference between plastic sheets and PVC sheets as they both refer to the same material.

- Q: Are plastic sheets resistant to cracking from impact?

- Yes, plastic sheets are generally resistant to cracking from impact.

- Q: Are plastic sheets resistant to staining?

- Yes, plastic sheets are generally resistant to staining due to their non-porous nature and smooth surface, which makes them easy to clean and maintain.

- Q: Can plastic sheets be used for boat windows?

- Yes, plastic sheets can be used for boat windows.

- Q: where can i buy sheet plastic for seat covers ?

- if you have to put plastic on your furniture , to use it, then why have it ?

- Q: What is the density of polyethylene foam board?

- Polyethylene foam plate density of 0.05 - 0.14g/cm3; the tensile strength is more than 0.15Mpa compressive strength more than 0.15Mpa tear strength more than 4.0N/mm

- Q: Can I use all these plastics sheets and duct tape I bought after 9/11 to protec me from e. bola?

- Hide in your Y2K bunker till this all blows over

- Q: that's all she wants me to bring over..should I worry ?

- Nope. You'll enjoy yourself. I promise. *wink*

Send your message to us

Plastic Sheets PVC Foam Board for Wall Cladding/Decorating - Best Selling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords