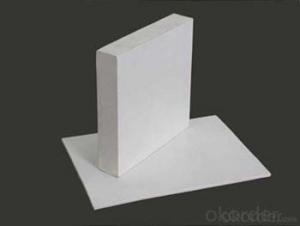

Plastic Sheets - PVC Board Foam Filled Closed-Cell Waterproof Fireproof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

1 | Product | PVC Foam board/sheet/panel | |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on | |

3 | Thickness | 1~ 30mm | |

4 | Density | 0.4~ 0.8g /cm 3 | |

5 | Brand | CMAX | |

6 | Certificate | SGS | |

7 | Weldable | Yes | |

8 | Foam Process | Cellular | |

9 | Packing | Carton box or wooden pallet packing | |

10 | production capability | 10000 pcs per month | |

11 | Life Span | >50 years | |

12 | Flame retardance | self-extinguishing less than 5 seconds | |

PVC foam board is made from polyvinyl chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

Product Features

•Excellent clarity, transparency and gloss

•Least thickness variation

•Non-toxic

•Smooth die-cutting

•Superior sealing and welding

•Excellent impact strength

•Higher processing yields

•Non-sticky

•Excellent printability with all common printing methods

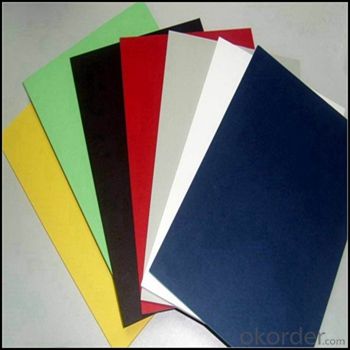

•Available in a range of tints and transparent and opaque colours

•Range of surface finishes (Glossy/Matt)

Product Application

Construction: show window, doors, light-absorbing shade, telephone booth.

Advertisement: Lamp-house,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability

Pictures

- Q: How thick are the PVC plates?

- PVC transparent board: high strength, high transparent plastic board, the products are white, sapphire, brown, coffee and other varieties. The product has high strength, high transparency, good weather resistance, non-toxic, hygienic and physical properties superior to organic glass. Widely used in equipment, guard board, interior, drinking water tank, liquid level display, etc..Product thickness: 2-20mm product maximum width: 1300mmProduct length: 100-10000mm recommended specifications: 1300 * 2000mm

- Q: What's the arc plastic board on the wheel?

- The rear wing does not have wheel turning and rubbing problems, but for aerodynamic considerations, the rear wing is slightly arched and protrudes outward. Now some car fender has been with the body as a whole, production at. But there are also independent wings of the car, especially the front wing, because the front wing has more chance of collision, independent assembly and easy replacement. TRIMS WHEEL (CAR) is mainly equipped for the decorative effect and the driver's individual needs. At the same time, due to aerodynamics, the wheel also has the function of reducing resistance

- Q: Are plastic sheets suitable for outdoor furniture?

- Plastic sheets are generally suitable for outdoor furniture due to their durability, weather resistance, and ease of maintenance.

- Q: what is the overlayer plastic sheet used on standard dvd and game case called?

- that's thoroughly pointless, i think of people might desire to easily be able to purchase video clips of On call for or Verizon and function the flexibility to maintain them continuously on like a saved folder, and then with comparable song on Itunes and vehicles might desire to come put in with iPod holders so which you will play that rather of CD's, haha I even have weird and wonderful philosophy.

- Q: Hi ! I want to print a double side sheet of transparent plastic , but the colors get all dizzy becaus of the transparancy , how can i print white on both sides of the plastic ?

- Actually, I had direct experience in using liquid watercolor (just superconcentrated pigment, I guess) I believe from Dick Blick, on yupo paper, which is pretty transparent, but a little cloudy-looking. You can't touch it without wearing rubber gloves at first though, or your paint will not stick to where the oils from your hands touched it. The paper comes pretty large, but I don't think it was quite that big, and I'm not sure where it was ordered from, but you may be able to find it online?? Good luck!

- Q: What are the common uses for plastic sheets?

- Plastic sheets have a wide range of common uses, including but not limited to: packaging materials, construction and building applications (such as roofing, windows, and insulation), protective coverings for furniture or flooring, signage and advertising displays, medical and healthcare equipment, automotive parts, and various DIY projects.

- Q: I suppose with an election just around the corner I better hold on to them...

- Yes you should hold on them. If the country is leaning towards voting for a Democrat, I'm sure another terrorist attack will be imminent. You can never have enough plastic sheets and duct tape.

- Q: What is the weight of a standard plastic sheet?

- The weight of a standard plastic sheet can vary depending on its thickness and dimensions. However, on average, a standard plastic sheet typically weighs around 0.5 to 2 pounds per square foot.

- Q: What are my options? What's the name of these type of plastics?Id like to buy in bulk, raw sizes to get the lowest price possible..

- any big office supply store.

- Q: Are plastic sheets flexible?

- Yes, plastic sheets can be flexible depending on their thickness and composition.

Send your message to us

Plastic Sheets - PVC Board Foam Filled Closed-Cell Waterproof Fireproof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords