Plastic Sheets - Closed-Cell PVC Foam Board, Building Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

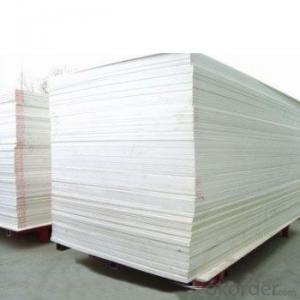

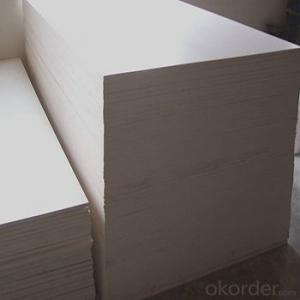

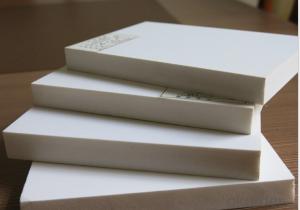

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

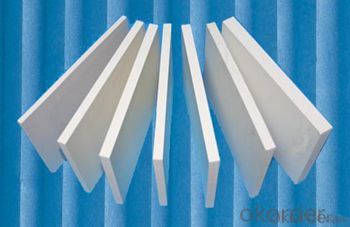

3. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

4.FAQ

1, How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect

2, Which factors can be customized?

Answer: Material, Color, Size, Packing ,Brand, delivery

3. Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

5.pictures

- Q: where do they sell Corrugated Plastic sheets?

- You can purchase them from any local sign company. This is the same product that many realtors politicians use for yard signs. I'm not sure what a plain, unprinted sign will cost. Typical yard sign 18x24 is around $12-16 (but that usually includes printing the stake).

- Q: Can plastic sheets be used for pool covers?

- Yes, plastic sheets can be used for pool covers. They are commonly used as a cost-effective option to protect and maintain the cleanliness of the pool by preventing debris from entering the water. However, it is important to note that specific types of plastic sheets, such as those designed for pool cover applications, should be utilized to ensure durability and proper fit for the pool.

- Q: Are plastic sheets resistant to bending?

- Yes, plastic sheets are generally resistant to bending due to their rigid and inflexible nature.

- Q: Are plastic sheets resistant to warping or bending with heavy loads?

- Yes, plastic sheets are generally resistant to warping or bending with heavy loads. They are designed to be durable and have high structural integrity, allowing them to withstand heavy loads without deforming or bending.

- Q: Are plastic sheets transparent to radio waves?

- No, plastic sheets are not transparent to radio waves.

- Q: Can plastic sheets be used for machine covers?

- Yes, plastic sheets can be used for machine covers. Plastic sheets are durable, lightweight, and resistant to various elements, making them suitable for protecting machines from dust, moisture, and other potential damages. They can be easily customized and are cost-effective compared to other materials, making them a popular choice for machine covers in various industries.

- Q: Can plastic sheets be used for window replacement?

- Yes, plastic sheets can be used for window replacement. Plastic sheets such as acrylic or polycarbonate can provide a cost-effective and temporary solution for replacing windows. They are lightweight, transparent, and offer some level of insulation and protection against the elements. However, it's important to note that plastic sheets may not match the durability and long-term performance of traditional glass windows.

- Q: If not, what kind of screws should I use?

- Yes, and coarse thread wood screws work too.

- Q: Are plastic sheets suitable for electrical enclosures?

- Yes, plastic sheets are suitable for electrical enclosures. They are non-conductive and can provide insulation and protection for electrical components. Additionally, plastic sheets are often lightweight, durable, and resistant to corrosion, making them a popular choice for various electrical enclosure applications.

- Q: Can plastic sheets be used for hygienic wall cladding?

- Yes, plastic sheets can be used for hygienic wall cladding. Plastic sheets, such as PVC panels, are commonly used for wall cladding in areas that require high levels of hygiene, such as commercial kitchens, hospitals, and food processing facilities. These sheets are easy to clean, resistant to moisture and chemicals, and provide a smooth and durable surface that helps maintain a hygienic environment.

Send your message to us

Plastic Sheets - Closed-Cell PVC Foam Board, Building Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords