Plastic Sheets - Plastic PVC Sheet/Board/Plate Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

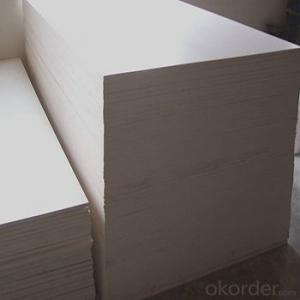

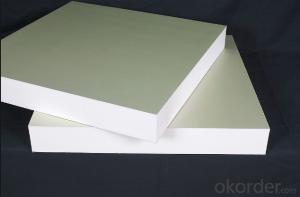

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

Proportion | JC/T 562-1994 | g/cm3 | 1.45-1.65 | |

Heat distortion temperature | ASTM D-648 | 1.82Mp | ºC | 61-67 |

Temperature Range | ºC | -20~+50 | ||

Thermal conductivity | ASTM C-177 | W/mºC | 0.16 | |

Coefficient of thermal expansion | ASTM D-696 | cm/cm/ºC | 6.3E-05 | |

Strength | ISO 6603/1 | 2mm sheet | J | 45-60 |

Yield Tensile Strength | ASTM D-638 | 10mm/ min | MPa | 52-66 |

Tensile Strength | ASTM D-638 | 10mm/ min | MPa | 39-53 |

Yield Elongation | ASTM D-638 | 10mm/ min | % | 3 |

Tensionset | ASTM D-638 | 10mm/ min | % | 140-160 |

Elastic modulus | ASTM D-638 | 1mm/ min | MPa | 2700 |

Bending strength | ASTM D-790 | 1mm/ min | MPa | 90-100 |

Flexural modulus | ASTM D-790 | 1mm/ min | MPa | 2200 |

Rockwell hardness | ASTM D-785 | Rockwell | 105-115 | |

Deflection | JC/T 562-1994 | Support Span 800mm, load 40kg | mm | 32 |

Oxygen index | JC/T 562-1994 | 43 |

2. FAQ

Q1. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q2. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

3.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4.Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

- Q: Are plastic sheets resistant to chemicals?

- Yes, plastic sheets are generally resistant to chemicals.

- Q: Are plastic sheets resistant to warping or shrinking under heat?

- Yes, plastic sheets are generally resistant to warping or shrinking under heat, as they have a high melting point and can withstand elevated temperatures without deforming. However, it's important to note that the exact behavior of plastic sheets can vary depending on the specific type of plastic used and the intensity and duration of the heat exposure.

- Q: Do plastic sheets have any impact on insulation efficiency?

- Yes, plastic sheets have an impact on insulation efficiency. Plastic sheets, such as vapor barriers, can help improve insulation efficiency by preventing the transfer of moisture and air through walls or ceilings. They act as a barrier that reduces heat loss or gain and helps maintain a more consistent indoor temperature, thus enhancing insulation effectiveness.

- Q: Can plastic sheets be used for safety guards in manufacturing?

- Yes, plastic sheets can be used for safety guards in manufacturing. They are commonly used due to their durability, flexibility, and transparency, which allows for visibility and protection against various hazards in the manufacturing process.

- Q: Are plastic sheets resistant to breakage?

- Yes, plastic sheets are generally resistant to breakage due to their flexibility and durable nature.

- Q: Are plastic sheets resistant to bacteria and mold growth?

- Yes, plastic sheets are generally resistant to bacteria and mold growth. Plastic materials, such as polyethylene or polypropylene, have non-porous surfaces that do not provide a suitable environment for bacteria or mold to grow. Additionally, some plastics can be treated with antimicrobial agents to further enhance their resistance to these microorganisms. However, it is important to note that the resistance may vary depending on the specific type of plastic and the conditions in which it is used.

- Q: There was like a plastic transparent sheet on the back of it. Some of it came off. And some of it is still there. The signature is still there too. Will it still work. Cause i dont want to peel itall off since if i do the sign will also come off.

- It may or may not work. Contact your card issuer and ask them to send you a replacement card. Some greedy banks may try to charge you for the replacement, but call them and make a big fuss - and they will waive the fee.

- Q: Are plastic sheets rigid or flexible?

- Plastic sheets can be both rigid or flexible, depending on their composition and thickness.

- Q: Why does wrapping a house with plastic sheeting, typically Tyvek, reduce advective heat loss?

- Tyvek okorder / ...

- Q: Do I use 2x6? 2x4?. ????????

- you put up a vapor barrier, plastic sheet with taped seams, first and then use DWC. Dry Wall Channel 16 inches on center. shot in with a ram set or hammer drilled with tap-cons. the ram set is less expensive. then put in rigid insulation. then drywall.

Send your message to us

Plastic Sheets - Plastic PVC Sheet/Board/Plate Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords