Plastic Sheets - Hollow Polypropylene Sheet for Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

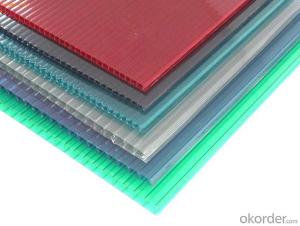

CMAX PP Plastic Hollow Sheet is an extruded twin wall plastic sheet consisting of two flat walls connected by vertical ribs. Eco-friendly PP Plastic Hollow Sheet is mainly manufactured from a high impact co-polymer polypropylene (PP) or polyethylene (PE) resin, which can be recycling, washable, durable and re-useable etc. CMAX Polypropylene PP Twin Wall Corrugated Plastic Hollow Sheets / Board / Signs has proved that it is suitable in the uses of packaging, advertising, construction, agriculture, industry and Pharmaceutical etc.

Specification:

1. Thickness: 2mm,3mm,4mm,5mm,6mm,7mm,8mm,10mm,12mm

2. Weight: From 250g/m2 to 3500g/m2

3. Standard Size: 2440mmx1220mm, 2000x1000mm, 1200x800mm, 1000x1000mm or as request

4. Grade:Corona Treated, Anti-Static, Conductive, UV Stabilized and Flame Retarded etc;

Feature:

CMAX Polypropylene PP Corrugated Plastic Hollow Sheet offers efficient solutions to a wide variety of applications. Compared to alternatives such as cardboard, metal or rigid plastic, Eco-friendly Twin Wall Corrugated Plastic Polypropylene PP Hollow Sheet offers the following unique advantages

1. Economical : both in use and purchase

2. Flexible : as a material and as application

3. Environmentally sound : recyclable

4. Water and moisture resistant

5. Approved for food packaging

6. Strong and durable

7. Lightweight

8. Good chemical resistance

9. Easy to print

Description | PP hollow sheet/PP corrugated sheet is a kind of environmental material, which is pollution-free and recyclable, made of polypropylene (PP) and polyethylene (PE) | |||||||||

Width | ≤2100mm | |||||||||

Length | As required. | |||||||||

Thickness | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 9mm | 10mm | 11mm | 12mm |

GSM | 250-500 | 300-600 | 600-900 | 800-1200 | 900-1600 | 1400-2000 | 1600-2000 | 1600-2200 | 2200-2400 | 2400-2600 |

Application | Packing | Transfer Box,mail box,display rack,partition,gift box,food packing,turnover box,dustbin,etc. | ||||||||

Advertising | Sign board,exhibition board,billboard,caution board,picture frame backing,digital printing and screen printing. | |||||||||

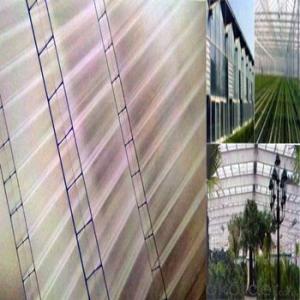

Decoration | Partitions,wall cladding,indoor and outdoor decoration,windows and false ceilings,floor cover,greenhouse roof. | |||||||||

Stationery and art design | It has multi-color,suitable for art design & various pattern box or delicate gift pack. | |||||||||

Feature | Light weight,rigid,strong and long time durable. | Waterproof,moisture resistance,excellent weather ability. | ||||||||

Chemical resistance,anti-impact,fade resistance. | Environmental friendly,recyclable,washable,non-toxic. | |||||||||

Easy to fabricate,custom-made cut shape. | Excellent surface for paints and inks easily,anti-corrosion. | |||||||||

Grade | Common,Corona Treated,Anti-Static,Conductive,UV Stabilized,etc. | |||||||||

Color | Clear,Black,White,Blue,Red,Yellow,Green,Pink,Or as required. | |||||||||

Advantage | Capacity:600MT per month; Prompt delivery; Factory Direct Selling; ISO-9001 | |||||||||

- Q: Is the extrusion plate the same as the foam board?

- Extruded board: the polystyrene resin and additives by extrusion process manufacturing have continuous uniform surface and obturator honeycomb structure plate some honeycomb structure is totally void of a plate type structure with obturator insulation materials (150-500Kpa) have the same pressure with low thermal conductivity values (only 0.028W/ M.K) has excellent insulation failure compressive strength compressive properties of 220-500Kpa

- Q: Are there large plastic acitate sheets that can be used for stenciling? larger than 8.5x11?

- OKorder has a vast amount of stencil supplies.

- Q: why do people put plastic sheeting down before pouring concrete? I think i know but want to here from experts.?

- Putting plastic down before pouring concrete, is to prevent any water in the concrete from being absorbed by the underlying soil. If the water were to be absorbed by the soil, the process of the concrete 'curing' properly would be affected.

- Q: Can plastic sheets be used as a replacement for glass in windows?

- Yes, plastic sheets can be used as a replacement for glass in windows. Plastic sheets such as acrylic or polycarbonate are lightweight, durable, and offer good insulation properties. They are also less prone to breaking and can be more cost-effective compared to glass. However, plastic sheets may have lower optical clarity and can be susceptible to scratching over time.

- Q: PC plastic PS plastic what is the difference between attention is the difference?! Come and answer

- Common products: Stationery, cups, food containers, household appliances, electrical fittings, etc. PC is the abbreviation of polycarbonate,PC sheets are especially suitable for making glasses lenses, and the introduction of silica groups into PC molecular chains can improve their hardness and scratch resistance. PC as a high refractive index for the production of plastic core material of high temperature resistant optical fiber, if in the molecular chain of PC C - H C - F chain chain is replaced, can reduce the absorption of visible light, can effectively reduce the loss of signal transmission way. In addition, PC has good transparency. It is widely used and has potential in transparent window materials, high-rise building curtain walls, airports and stadiums, transparent building materials, etc. in the future, the emphasis will be on improving surface hardness and antistatic properties.

- Q: Perforate a sheet of plastic with a laser

- You want to punch in the workpiece do not burn workpieces, must use high power CO2 laser machine, on the workpiece marking speed, that is to say at a certain point of the workpiece energy will stay a short time, you can do not burn plastic.

- Q: What are the temperature limits for plastic sheets?

- The temperature limits for plastic sheets can vary depending on the type of plastic. However, most plastic sheets have a temperature range of -20°C to 70°C (-4°F to 158°F) before they may start to deform or lose their structural integrity. It is important to consult the specific specifications or manufacturer guidelines for the plastic sheet in question to ensure proper usage within the recommended temperature limits.

- Q: Can plastic sheets be used for DIY face shields?

- Yes, plastic sheets can be used for DIY face shields. They provide a transparent barrier that helps protect the face from potential exposure to droplets and airborne particles. However, it is important to ensure that the plastic sheet used is of sufficient thickness and clarity to provide adequate protection. Additionally, the DIY face shield should cover the face completely and be properly secured to ensure maximum effectiveness.

- Q: Can plastic sheets be used for protective packaging?

- Yes, plastic sheets can be used for protective packaging. They are commonly used to wrap and protect various items during storage, shipping, or transportation. Plastic sheets provide a barrier against dust, moisture, and other potential damages, ensuring that the contents remain safe and intact. Additionally, plastic sheets can be easily cut and shaped to fit different objects, making them a versatile option for protective packaging.

- Q: Do I use 2x6? 2x4?. ????????

- Well I have been a carpenter all of my adult life and I am 76 now and retired. (tired to) To start with I would use a product called DRY-LOCK on your concrete walls, Next I would put a border of 1X4s top, bottom, and ends, installed useing toggle bolts with flat heads so you can counter-sink the head of the bolt 3/16 inch bolts is enough the length being determined by the thickness of the congrete block + 1/2 inch sheetrock + allow about 1 inch, My guess is about 3 1/2 to 4 inches long.Then put in your studs, useing 1X4s 16 inchs on center. The bolts only need to be about 36 inches apart. Make sure you measure correct and that you center your sheetrock at the end of each sheet. use 1inch or 1 1/8 inch drywall screws. your not going to support a house your only going to support the sheetrock, Don't forget to do your wireing? and they make elect. boxes for just that thickness. Have some in my basement, Unless your in a hurry, you can work as hard or as slow as you want, you have a cover over your head. Also I would plan on putting in a drop ceiling, it covers up a lot of overhead stuff, and gives your Electric wires a place to run. Good Luck

Send your message to us

Plastic Sheets - Hollow Polypropylene Sheet for Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords