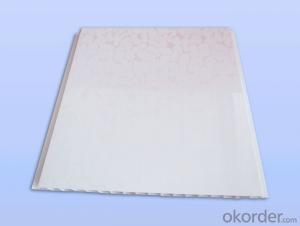

Plastic Sheets - Bottom Price Promotion Personalized Traffic Sign PVC Foam Board Weight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Detailed specifications:

Thickness 1-33mm

Width 1220mm, 1560mm, 2050mm

Length As requirement

Color: white,black etc.

We also can manufacture according to your requirement.

Advantage:

1. Waterproof, Moisture/Water resistant, less rotten, proven under salt water condition, UV-resistance

2. Fire retardant and self-extinguishing

3. Sound-insulated; Non-toxic

4. High recyclable, eco-friendly, saving forest resources

5. Weather resistant, suitable from minus -30 to 70 centigrade degree

6. Well done of Termites, insects, and moldy-proof

7. Easy to nail, hammered, drilled, sawed, turned, glued, bended, printed, oiled, thermoforming

8. Easy to clean

9. No any benzene and the formaldehyde discharge,Non-toxic

Picture

FAQ:

1. Sample: Can I get samples?

Sample normally is free of charge but the air express fee is usually borne by customer;

2. Price: Could I get your company product price ?

Please kindly tell us your requested details, such as thickness, color,weight/m2, raw materials request, end application etc. Later we will offer you promptly.

3. Is OEM or Custom Order available? Yes

4. Which Payment Terms ?

T/T:Telegraphic Transfer (wire transfer), West Union, Paypal, L/C etc.

5. Lead Time: How soon we can get the shipment?

We will arrange production since the order and payment are confirmed, we will take 7-15 days to arrange production and book shipping space in advance before goods is ready.

- Q: I got a new tripod for my camera recently and would like to convert my old one into something resembling a nightstand or tv tray; I was thinking of using a board or flat surface with a nut or something similar attached to the bottom that would be the right thread size to screw onto the tripod. The idea would be to have a platform/tabletop surface that could have its height easily adjusted up and down; I know they make things like these, but I'd rather not pay $85.00 for a 15 inch piece of plastic that's ready-made to screw on to tripods (like this: http://amzn.to/9k4i2N) or $150.00+ for an adjustable end table (like this: http://amzn.to/a6UExN) when I can probably make something very similar myself for less than 5 bucks with the right equipment. problem is, I'm not very handy with this type of stuff and don't really know how to go about attaching a threaded hole to a board or what type of threaded hole I should even be looking for. I figure it can't be that hard, though. Any help?

- I've made specialty 'adapters' for several tripods to correct lens focal length (in virtual tour productions), by making a slim molding from wood, that mimics the profile of the camera 'wedge' that locks down on the tripod. The wedge can be screwed into whatever 'shelf' material you want from there. That top is then removable, but still fairly secure, provided you don't overload it. Mine was easy with the table saw (for the angles), but perhaps you could make one with a hand saw? Good luck.

- Q: I am in the process of building a box and I wanted to use plastic to build it. I want to find a plastic that is strong, yet light weight and durable. The design calls for thinner sheets of plastic. So my question is what type of plastic is strong, thinner, lightweight, and still on the cheap side, and where would I be able to buy this plastic?

- Home Depot seels 10 mill plastic.

- Q: looking for felxiable mirorred plastic no more than a 1/2 inch ..that i can order online or go to a store in portland oregon and buy in 3 ft sections making a wearable design.. in sliver and gold or black ... any help where to get this would help.. Thanks

- I believe Mylar like balloons are made from is the material you are looking for You can buy it on line or from hydrophonic stores.

- Q: What is the PP board, PE board?

- Polypropylene and polyethylene are non-toxic plastic, with lighter and high toughness, therefore used as substitute for wood chopping board. But don't change over the years, with a long time have board should pay attention to the debris produced, eat or not good.

- Q: Are plastic sheets environmentally friendly?

- No, plastic sheets are not environmentally friendly. They are made from non-renewable fossil fuels, take hundreds of years to decompose, and contribute to pollution and waste in our ecosystems.

- Q: I am giving my kitchen cupboards a makeover don't want to paint them so I thought covering them was best any ideas appreciated.thanks in advance

- most Diy stores sell this type of sticky back plastic

- Q: What are the weight limitations of plastic sheets?

- The weight limitations of plastic sheets can vary greatly depending on the type and thickness of the plastic. However, in general, plastic sheets have lower weight-bearing capacities compared to other materials like metal or wood. It is important to consider the specific application and consult the manufacturer's guidelines to determine the maximum weight that a plastic sheet can support safely.

- Q: I am making a craft project. I went to a craft store and purchased a yard of plastic in the fabric dept. I cut two 6X6 pieces and glued them with a water resistant glue. I allowed 24hrs. I then put water inside and a few hrs later noticed it was soaking through the plastic and leaking. I need a glue that will hold water inside. I hope this clarifies my question.

- Water resistant normally does not include immersion. It depends on the plastic. And fabric department through the plastic bother me - is the plastic itself water tight? If you make a bag of a square by holding up the 4 corners and pouring water in the sag, does water drip through? As a starting point, I would suggest looking on the packaging for E6000 and GOOP products (from the same company) and see whether they are okay for immersion in water. I use them outside, but don't recall. You may have to fold the seam and apply the glue to hold the seam so the water only touches the glue at a thin line. Aquarium silicone glue should work, but it won't stick to some plastics. I am not sure acrylic sheet comes as thin as you want and PVC has to be opaque, I believe, but both use a solvent cement that partially melts the plastic then evaporates. If the plastic is thermoplastic - it melts when heated - then you can seal the seams with an iron. Check a small piece of the plastic over a match or kitchen burner - the difference between melting and burning should be obvious.

- Q: Those yellow sheets of plastic or something that you cut your design into and then stick to the silk screen? what are they called i need to buy more.....

- polyethylene sheets... i don't even know what silk screening is but there's a little thing called Google. duh...

- Q: What are my options? What's the name of these type of plastics?Id like to buy in bulk, raw sizes to get the lowest price possible..

- Try your local Office Depot, or Staples. They should have what you are looking for and if not they can tell you where you can get them.

Send your message to us

Plastic Sheets - Bottom Price Promotion Personalized Traffic Sign PVC Foam Board Weight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords