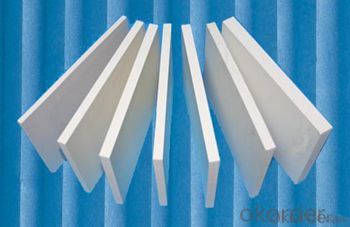

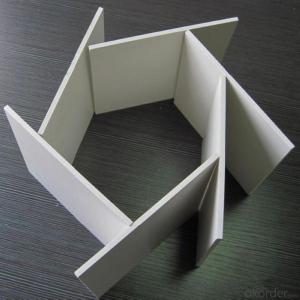

Plastic Sheets - 1mm - 20mm PVC Rigid Foam Board with 50+ Years Usage Life

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

3. Product Features

1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5. FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

6. Pictures of PVC Foam Board

7. Factory Pictures

- Q: I have tried a variety of tapes that all slowly fall off over time. I'm looking for a more permanent way to attach two flat sheets of plastic about 10x10 together to form a seam.

- You could try sewing them together. There are also zippers sold for sheet plastic, so you can make a temporary doorway when you need to seal off part of your house from construction dust. You could use that and just never open the zipper. Google peel and stick zipper.

- Q: For my Drawing on the Right Side of the Brain course, Betty Edwards includes a view finder containing an overhead projector sheet as one of the materials. I assumed any sheet of plastic (i.e. a plastic sleeve made for a binder) would work, but now I discovered she wants the reader to write on it using a white board marker (and wipe it off afterwards). Any ideas on how I can get a one or two overhead projector sheets, or else, are there any easy alternatives?

- Try an art store. You can often buy individual sheets of various kinds of paper and other materials. The ghetto way would be to scour your home for transparent plastic from product packages and see if any of them work. Lots of things come wrapped in clear plastic, especially electronics. For example, a brand new laptop usually has a clear plastic film over the LCD for protection which would probably be ideal.

- Q: Can plastic sheets be thermoformed?

- Yes, plastic sheets can be thermoformed. Thermoforming is the process of heating a plastic sheet and then shaping it into a desired form using molds or tools. It is a commonly used method for manufacturing various plastic products such as packaging, trays, and containers.

- Q: how do we make a transparent plastic sheet translucent?or vice versa

- Rub the transparent sheet with fine sandpaper. Vice versa - polish it with successively finer grades of polish.

- Q: I am looking for a sheet that measures out to either 3'x5' or 4'x6' (1/8 thick). Anyone know of anywhere I can get it cheap?

- You'll have to go to a local plastic's retailer for that - check your Yellow Pages under Plastic - rods, sheets for a listing.

- Q: I have a FG700MS, and a strip of plastic is peeling off on the tortoise-shell pickguard, and I dunno if I'm meant to peel it off or not! LOL! It's quite new and I don't want to break it or anything, so does anyone know?

- If its just a see-through sticky plastic film that's like a giant see-through sticker covering the surface of the pick guard, it's been put there to protect the finish on the pick guard when it's in a shop or being transported. It's meant to be taken off cos it's just there to keep things clean until somebody buys it. It won't affect the guitar if you leave it on, cos I bought a Les Paul and after a few weeks I taught the pick guard paint was blistering but when i pulled at it....It was a protective plastic sticker that Gibson had put on it.

- Q: What is the density of polyethylene foam board?

- The closed cell foam board is made of high pressure polyethylene low foamed closed cell foam board, and it has no change with sealant.

- Q: It's Canon ip4500 Ink jet printer.Thanks!

- Good question....hard to say as the listed supported media specifications did not list it as a compatible media type, but neither did it list it as a media type you cannot use according to the manual. So with that said, I think that you can use overhead transparencies as long as you get ones that are designed and made for inkjet printers. Best of luck.

- Q: my cat has peed numerous of times on my bed. i cleaned the sheets and everything. but of course the mattress stinks! my friend told me that there are plastic sheets that go over your mattress and under your sheet that go overs your mattress. it'll block away the smell and keep the mattress cleaner. but ive tried looking for it on the internet and can't find a name for it. where would they sell these? sears? walmart? target?...thanks

- They are plastic mattress covers, you can find them at Wal-mart. They are inexpensive. You can try cleaning the mattress with some white vinegar to neutralize the cat urine odor also.:)

- Q: Can plastic sheets be used for DIY hydroponic systems?

- Yes, plastic sheets can be used for DIY hydroponic systems. They can be used to create troughs or channels to hold the nutrient solution and support the plants. Plastic sheets are often preferred for their durability, affordability, and ease of maintenance in hydroponic setups.

Send your message to us

Plastic Sheets - 1mm - 20mm PVC Rigid Foam Board with 50+ Years Usage Life

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords