Plastic Sheets - Plastic PVC Sheet, PVC Foam Board for Frames Photo Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

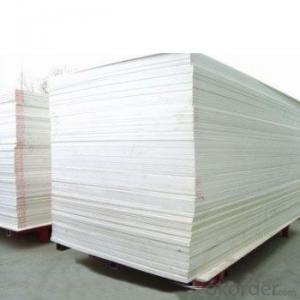

Plastic pvc sheet, pvc foam board for frames photo design

Quick Details

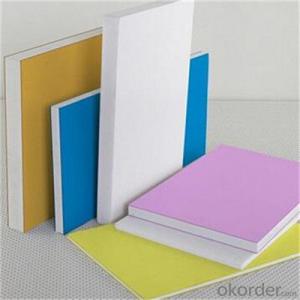

| Place of Origion: | Zhejiang | Material: | PVC |

| Certicification: | SGS | Colour: | All Kinds of Colours |

| Size: | Customize Size | Thickness: | 1-20mm |

| Package: | Carton Box | Advantages: | Eco-Friendly |

Packagng&Delivery

Packaging Details:PE film,plastic packages or carton box

Delivery Detail:10 to 15 days

Plastic pvc sheet, pvc foam board for frames photo design

What is PVC foam board?

A kind of high-tech product, is produced by special machinery and technology processing, has excellent corrosion resistance, insulation, and have a certain mechanical strength. The main material new PVC resin can be foamed and extruded into a special sheet with many advantages and uses wildly. It's a good substitute for wood.、

Appilication

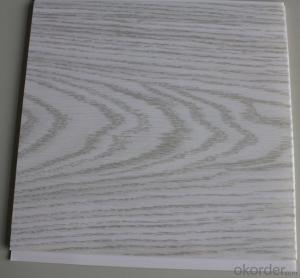

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4. Architectural decorations and upholstery.

5. Sanitarywares, kitchen cabinet, washroom cabinet

- Q: I had to put a plastic sheet over my garden because it has been raining non-stop. If I leave it up when the sun is out, will the UV rays be able to pass thru it?

- If it is clear plastic, remove it. This could magnify the suns rays and burn your plants. If it is colored plastic, I doubt the rays will go through it.

- Q: Behr has special paint, can this be done with other paint?

- you do not need to have special paint unless you are wanting a certain look. If you are wanting it to look like it has almost a crackle look, using plastic sheeting would be an easy way. If you are just wanting to almost blend 2 colors, they make this 2 headed roller that comes with a certain paint tray that you would pour 2 different colors in and put them on the wall at the same time. It is a really nice look. You could also do this with a sponge and a regular roller but this would probably take you longer to do. But any type of idea like that, you wouldn't need a specific type of paint unless you're going for a certain look.

- Q: looking for felxiable mirorred plastic no more than a 1/2 inch ..that i can order online or go to a store in portland oregon and buy in 3 ft sections making a wearable design.. in sliver and gold or black ... any help where to get this would help.. Thanks

- I believe Mylar like balloons are made from is the material you are looking for You can buy it on line or from hydrophonic stores.

- Q: What's the best glue for a plastic plate?

- Plastic board: plastic board is made of plastic, and plastic is synthetic macromolecule compound. It can change the shape of the body freely. The plastic is made of synthetic or condensation polymerization with monomer raw materials, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives, it is the main component of synthetic resin.

- Q: I admit I haven’t seen these in years and I'm not sure I’m even using the right term. The only slide shows I’ve seen or made in the past 7 years were Power Point ones.But several years ago I remember these clear plastic sheets that could be printed on with my simple, cheap, disposable printer (a Lexmark that came free with my PC).I have a little 3 in 1 Inkjet (Epson Stylus CX4800) and I want to be able to print on thin sheets of plastic. QUESTIONSDo they still sell those sheets?What are they called?Who sells them?Do you think they would work in an Inkjet or would I need to find someone with a Laser or other type of printer?Thanks

- They are called overhead transparencies like the previous posts say. Make sure you find the one that says for inkjet printers if you are going to use an inkjet. The bad thing is, less and less people are manufacturing them so they are pretty expensive now compared to 4 or 5 years ago. I was shopping for some a few months ago and whoa, the price tripled from before. Anyhow good luck, STAPLES, Office Max, Office Depot. Walmart and Target used to sell em, but not anymore.

- Q: What are the different types of plastic used in plastic sheets?

- There are several different types of plastic used in plastic sheets, including polyethylene, polypropylene, polyvinyl chloride (PVC), polycarbonate, and acrylic. Each type of plastic has its own unique properties and characteristics, making them suitable for various applications.

- Q: I suppose with an election just around the corner I better hold on to them...

- What were you supposed to do with the originally? Seal your house air tight? Several Americans died from doing just that that after 9/11.

- Q: Are plastic sheets UV resistant?

- Yes, plastic sheets can be made UV resistant by incorporating additives such as UV stabilizers during the manufacturing process.

- Q: How do I find on the internet a plastic manufacturer that can glue two 1/4 thick sheets of acryllc together?

- Why don't you just get a piece of 1/2 acrylic?

- Q: Im looking for a place that sells sheets of Lenticular Len's. Its those plastic sheets that people use as decoders.

- Lenticular Sheet

Send your message to us

Plastic Sheets - Plastic PVC Sheet, PVC Foam Board for Frames Photo Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords