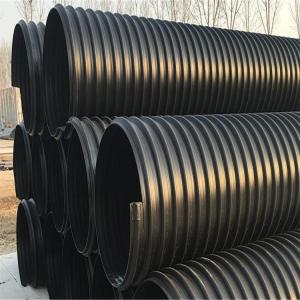

Plastic Pipe Push Fittings Steel Mesh Skeleton PE Pipe for Underground Coal Mine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Material: | Specification: | Length: | |||

| Thickness: | Standard: | Pressure: | |||

| Color: | OEM: | Working life: | |||

| Feature: | bending property: | Application: | |||

| Origin: | Production Techinque: | Ranking: |

Specifications

1.superior wearability

2.superior temperature resistant

3.superior impact resistant

Applications scope:

steel mesh skeleton PE composite Pipe can use in chemical industry :manufacture industry of acid ,alkali and salt ;transmission or discharging pipeline of corrosive gas, fluid and solid powder in industries including petrochemical,fertilizer,persticide,pharmacy,chemical,mining,plastic and rubber industry.

Oil and gas fields: oil-contained wastewater, gas field misture, polymer liquor reinjection to oil well, twice and triple oil extraction and transmission pipelines.

Mines: ore pulp, tailings, vent pipes and engineering pipes.

Texitile, printing, dyeing and paper industry: transmission or discharging pipeline to transport corrosive media.

Municipal constructions: transmission pipelines of constructional water supply and drainage, drinking water, natural gas and fuel gas.

Non-ferrous metal: seawater transmission, underdrain transmission pipe, discharging pipes and irrigation water pipe, etc.

Agriculture: deep-well pipes, strainer pipes, underdrain transmission pipe, discharging pipes and irrigation water used in desalinator, seaside power plant and port cities.

Thermoelectricity engineering: process water, recycled water and waste residue transmission in thermoelectricity projects.

Express highway: underground drainpipes and cable conduits.

.

Heat Preservation:

steel mesh skeleton PE composite Pipe not less than 25mm in thickness are used to wrap around pipeline surface. Buried under ground, it will not absorb water and distort, thus its service life keeps the same with the pipeline.

- Q: Can plastic pipe fittings be used for chemical processing plants?

- Plastic pipe fittings can be used for chemical processing plants, provided that the fittings are specifically designed and manufactured to withstand the specific chemicals and operating conditions involved in the plant's processes. It is important to ensure compatibility between the chemicals and the material of the fittings, as certain chemicals may react with or degrade certain types of plastics. Additionally, the fittings should meet industry standards and regulations for chemical processing plants to ensure safety and reliability.

- Q: What are the different pressure ratings for plastic pipe fittings?

- The pressure ratings for plastic pipe fittings vary depending on the type of plastic used and the specific application. Common pressure ratings for plastic pipe fittings range from 80 psi (pounds per square inch) to 200 psi. However, it is important to consult the manufacturer's specifications and guidelines to determine the appropriate pressure rating for a specific plastic pipe fitting.

- Q: Can plastic pipe fittings be used for irrigation systems in sandy soils?

- Yes, plastic pipe fittings can be used for irrigation systems in sandy soils. Plastic pipe fittings are often used in irrigation systems due to their durability and resistance to corrosion. They are able to withstand the abrasive nature of sandy soils and provide a reliable connection for the pipes used in the system. Additionally, plastic fittings are lightweight and easy to install, making them a practical choice for irrigation systems in sandy soils.

- Q: Can plastic pipe fittings be used for stormwater infiltration systems?

- Yes, plastic pipe fittings can be used for stormwater infiltration systems. These fittings are typically made from durable and corrosion-resistant materials such as PVC or HDPE, which are well-suited for underground applications. Plastic pipe fittings offer the advantage of being lightweight, easy to install, and resistant to chemical reactions commonly found in stormwater. Additionally, their smooth interior surfaces minimize friction and allow for efficient water flow in infiltration systems.

- Q: How do plastic pipe fittings work?

- Plastic pipe fittings work by connecting sections of plastic pipes together in a leak-proof manner. They are designed with various shapes, sizes, and connections to accommodate different pipe systems. These fittings usually have threads, sockets, or grooves that allow them to be securely attached to the pipe ends. The fittings create a tight seal using compression, glue, or heat fusion methods, ensuring that the pipes remain connected and prevent any leakage.

- Q: How are plastic pipe fittings manufactured?

- Plastic pipe fittings are typically manufactured through a process called injection molding. In this process, plastic resin is melted and injected into a mold cavity, which is shaped like the desired fitting. The resin is then cooled and solidifies, allowing the fitting to be ejected from the mold. This method enables mass production of plastic pipe fittings with consistent quality and precise dimensions.

- Q: Can plastic pipe fittings be used for chemical storage systems?

- No, plastic pipe fittings should not be used for chemical storage systems as they may not be able to withstand the corrosive nature of certain chemicals and can lead to potential leaks or failures in the system. It is recommended to use fittings specifically designed for chemical storage applications, such as those made from corrosion-resistant materials like stainless steel or high-density polyethylene (HDPE).

- Q: Are plastic pipe fittings resistant to soil movement and settlement?

- No, plastic pipe fittings are not generally resistant to soil movement and settlement.

- Q: Can plastic pipe fittings be used for chemical storage facilities?

- No, plastic pipe fittings are generally not suitable for chemical storage facilities as they may not have the required chemical resistance and could lead to leaks or contamination. It is recommended to use corrosion-resistant materials such as stainless steel or specialized chemical-resistant plastics for these applications.

- Q: Do plastic pipe fittings expand and contract with temperature changes?

- Yes, plastic pipe fittings do expand and contract with temperature changes.

Send your message to us

Plastic Pipe Push Fittings Steel Mesh Skeleton PE Pipe for Underground Coal Mine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords