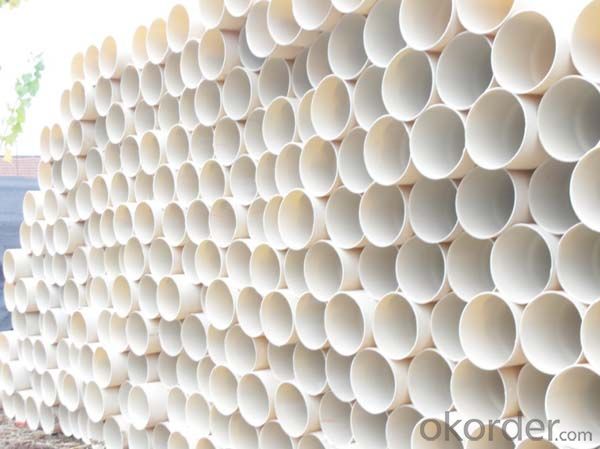

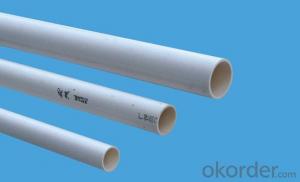

UPVC Water Pipes/underground Pvc Pipe Irrigation on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

pvc pipe for water drainage

1.Specification of pvc pipe:40mm-400mm

2.Thickness of pvc pipe:1.2mm-7.0mm

3.ISO certified.

Properties of pvc pipes:

1. Material: pvc pipe unplasticized polyvinyl chloride

2. Standard: GB, ISO9001, ISO14001

3. Color: white pvc pipe, grey pvc pipe , etc.

4. Specific Gravity, g/cm3, 20(C): 1.35 - 1.55

5. Vicat Softening Temperature, (C) >=79

6. Longitudinal Reversion, %, 150(C) <=5< span="">

7. Dichloromethane Resistance Test: No attack

8. Falling Weight Impact Test, TIR, %, 0(C) <=10< span="">

9. Tensile Yield Strength, Mpa >=40

10. Fitness of Water Tightness Test: No Leakage

11. Fitness of Air Tightness Test: No Leakage

Features of pvc pipes :

1) Light weight, easy to load and unload: PVC pipe is very light, convenient to handle loading unloading, and installing.

2) Good chemicals and drugs resistance: PVC pipe has its excellent resistance to the erosion caused by acids and alkalines, a great help to the chemical industries.

3) Small resistance to fluidity: The smooth surface reduces resistance to the fluids. Its roughness coefficient is only 0.009, much less than other pipes, Under same discharges, smaller cabibre of the pipe can be uesd.

4) Strong mechanical strength: Good resistance to water pressure, outside impact and pressure, is satisfied under any conditions.

5) Good electrical insulation: excellent insulation nature against electricity. the pvc pipe can be served as conduits and pipes in construction cable and wire.

6) Water quality unaffected: The solution tests on the PVC pipe show no affect on water quality when the water flows through is. It is considered the best piping material for running water works.

7) Simple installation: Very easy to connect, thus much time and laborcost may be saved.

Application of pvc pipes:

1) Structure Engineering, home water supply and drainage |

Specifications of the pvc pipe:

Outer Diameter (mm) | Wall thickness(mm) | |||||||

2.5MPA | 2.0MPA | 1.6MPA | 1.25MPA | 1.0MPA | 0.8MPA | 0.63MPA | ||

φ20 | 20*2.3 | 20*2.0 | ||||||

φ25 | 25*2.8 | 25*2.3 | 25*2.0 | |||||

Φ32 | 32*3.6 | 32*2.9 | 32*2.4 | 32*2.0 | ||||

Φ40 | 40*4.5 | 40*3.7 | 40*3.0 | 40*2.4 | 40*2.0 | |||

Φ50 | 50*5.6 | 50*4.6 | 50*3.7 | 50*3.0 | 50*2.4 | 50*2.0 | ||

Φ63 | 63*7.1 | 63*5.8 | 63*4.7 | 63*3.8 | 63*3.0 | 63*2.5 | 63*2.0 | |

Φ75 | 75*8.4 | 75*6.9 | 75*5.6 | 75*4.5 | 75*3.6 | 75*2.9 | 75*2.3 | |

Φ90 | 90*10.1 | 90*8.2 | 90*6.7 | 90*5.4 | 90*4.3 | 90*3.5 | 90*2.8 | |

Φ110 | 110*10.0 | 110*8.1 | 110*6.6 | 110*5.3 | 110*4.2 | 110*3.4 | 110*2.7 | |

Φ125 | 125*11.4 | 125*9.2 | 125*7.4 | 125*6.0 | 125*4.8 | 125*3.9 | 125*3.1 | |

Φ140 | 140*12.7 | 140*10.3 | 140*8.3 | 140*6.7 | 140*5.4 | 140*4.3 | 140*3.5 | |

Φ160 | 160*14.6 | 160*11.8 | 160*9.5 | 160*7.7 | 160*6.2 | 160*4.9 | 160*4.0 | |

Φ180 | 180*16.4 | 180*13.3 | 180*10.7 | 180*8.6 | 180*6.9 | 180*5.5 | 180*4.4 | |

Φ200 | 200*18.2 | 200*14.7 | 200*11.9 | 200*9.6 | 200*7.7 | 200*6.2 | 200*4.9 | |

Φ250 | 250*11.9 | 250*9.6 | 250*7.7 | 250*6.2 | ||||

Φ315 | 315*15.0 | 315*12.1 | 315*9.7 | 315*7.7 | ||||

Φ400 | 400*19.6 | 400*15.3 | 400*12.3 | 400*9.8 | ||||

- Q: Are plastic pipe fittings suitable for mining operations?

- Yes, plastic pipe fittings can be suitable for mining operations. Plastic pipe fittings offer several advantages such as corrosion resistance, lightweight construction, and ease of installation. Additionally, plastic pipe fittings can withstand high pressures and are durable, making them suitable for various mining applications. However, the specific requirements and conditions of each mining operation should be considered to ensure proper selection and installation of plastic pipe fittings.

- Q: What quota should plastic tube be fitted?

- In the pipeline installation, the plastic flange sleeve quota can be carried out according to the following conditions: installation engineering, plastic pipe installation, plastic flange installation, included in the flange valve

- Q: How to connect the steel tube and the steel tube?

- Characteristics of electric fusion welding:The electric heating welding technology is easy to construct and quick to implement. It can be used for welding and weldingThe welding reliability is good, and the strength and density are better than other connection methodsKeep the inner wall of the pipe smooth, without affecting the flow area

- Q: Are plastic pipe fittings more affordable than metal pipe fittings?

- Yes, plastic pipe fittings are generally more affordable than metal pipe fittings.

- Q: What is the purpose of plastic pipe fittings?

- The purpose of plastic pipe fittings is to connect and join different sections of plastic pipes together, ensuring a secure and leak-free connection. These fittings allow for easy installation, maintenance, and repair of plumbing and irrigation systems. They also provide versatility and adaptability, as they can be used with various types and sizes of pipes.

- Q: How do plastic pipe fittings compare to polypropylene fittings?

- Plastic pipe fittings and polypropylene fittings are both types of plastic fittings commonly used in plumbing systems. However, there are some differences worth noting. Plastic pipe fittings are a broad category that includes fittings made from various types of plastic materials, such as PVC, CPVC, and ABS. On the other hand, polypropylene fittings are specifically made from polypropylene, a thermoplastic polymer known for its high chemical resistance and durability. In terms of performance, polypropylene fittings generally offer superior chemical resistance, making them more suitable for applications involving corrosive or aggressive fluids. They are also known for their high temperature resistance and mechanical strength. Plastic pipe fittings, on the other hand, can vary in terms of quality and performance depending on the specific material they are made from. Another important aspect to consider is the ease of installation. Both plastic pipe fittings and polypropylene fittings are typically designed for solvent welding or using mechanical connections. However, polypropylene fittings often have a more precise and secure fit due to their tighter tolerances, which can simplify the installation process and reduce the risk of leaks. Ultimately, the choice between plastic pipe fittings and polypropylene fittings depends on the specific application requirements, such as the type of fluid being transported, the temperature and pressure conditions, and the chemical compatibility needed. It is important to consult with professionals or follow the manufacturer's recommendations to ensure the right choice for each individual case.

- Q: Can plastic pipe fittings be used for mining applications?

- Yes, plastic pipe fittings can be used for mining applications. Plastic pipe fittings, such as those made from high-density polyethylene (HDPE), are often used in mining operations due to their resistance to corrosion, abrasion, and chemicals. They are also lightweight, easy to install, and cost-effective compared to other materials. Additionally, plastic pipe fittings can withstand high pressures and temperature variations, making them suitable for various mining processes and applications.

- Q: Can plastic pipe fittings be used in fire evacuation systems?

- No, plastic pipe fittings are not suitable for use in fire evacuation systems. Fire evacuation systems require materials that are able to withstand high temperatures and are fire-resistant. Plastic fittings are not designed to meet these requirements and can melt or burn when exposed to fire, compromising the safety and effectiveness of the system.

- Q: Can plastic pipe fittings be used for chemical dosing in water treatment?

- Yes, plastic pipe fittings can be used for chemical dosing in water treatment. Plastic pipe fittings are commonly used in water treatment processes due to their resistance to corrosion, durability, and affordability. They are suitable for handling a variety of chemicals used for dosing in water treatment, such as chlorine, coagulants, flocculants, and pH adjusters. However, it is important to select the appropriate type of plastic pipe fittings that are compatible with the specific chemicals being dosed to ensure safe and efficient water treatment operations.

- Q: Can plastic pipe fittings be used for power plant cooling systems?

- Yes, plastic pipe fittings can be used for power plant cooling systems. Plastic fittings, such as PVC or CPVC, are commonly used in cooling systems due to their corrosion resistance, durability, and cost-effectiveness. These fittings can withstand the temperature and pressure requirements of power plant cooling systems, making them a suitable choice for such applications.

Send your message to us

UPVC Water Pipes/underground Pvc Pipe Irrigation on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords