Push Fit Plastic Pipe Fittings for Industrial Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Products

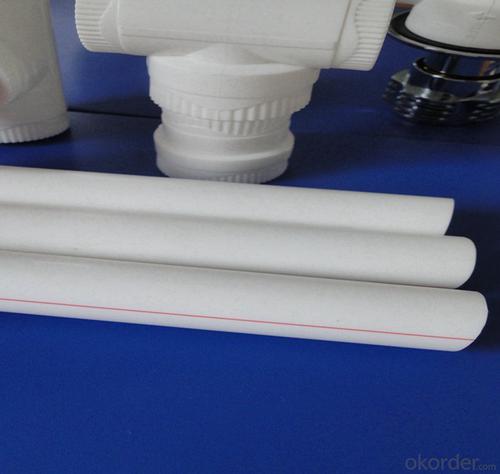

PP-R pipes are made of Polypropylene Random ,which has comprehensive physical and chemical property ,as well as Hygiene property.

With the high-quality materials .Minde PP-R pipes meet the DIN8077/8078 standard .Depending on the pressure ,the pipes can be used in temperature up to 70°Cwith an extrapolated service life up to 50 years .

Product Show

Specifications

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | customized |

5.MOQ: | 500pcs |

6.Samples Time: | (1)4-5days-If you want to customize your logo. |

(2)1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Advantages

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Feature

1)Pressure Rating: 1.0Mpa,1.25MPa, 1.6MPa, 2.0MPa ,2.5MPa

2)Colors: Green, White, Grey, Red, Blue, Yellow and other color on request

3)Certification: ISO9001, ISO14001,CE, ROHS, SGS and so on

4)Standard: DIN8077/8078

5)Applications: Cold or hot water supply

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, MoneyGram.

Q5: What you offer?

A5: Any kinds of goods you need, just send us the request, we will reply you back with the details very soon.

- Q: What types of plastic pipe fittings are available?

- There are various types of plastic pipe fittings available, including but not limited to couplings, elbows, tees, reducers, adapters, unions, caps, and plugs. These fittings are designed to connect and join different sections of plastic pipes, allowing for easy installation and maintenance of plumbing systems.

- Q: Are plastic pipe fittings resistant to waterborne bacteria?

- Yes, plastic pipe fittings are generally resistant to waterborne bacteria. They are often made from materials like PVC or CPVC, which have inherent antimicrobial properties that inhibit the growth and transmission of bacteria. Additionally, plastic fittings are typically non-porous and have smooth surfaces, making it more difficult for bacteria to adhere and multiply. However, regular maintenance, proper installation, and adherence to industry standards are necessary to ensure optimal resistance to waterborne bacteria in the long term.

- Q: Are plastic pipe fittings resistant to rodents?

- Yes, plastic pipe fittings are generally resistant to rodents. The material used in plastic pipe fittings is not appealing to rodents, and they do not chew through it as they would with other materials like wood or metal. Therefore, plastic pipe fittings are a reliable option to prevent rodent infestations in plumbing systems.

- Q: Can plastic pipe fittings be used for irrigation sprinkler systems?

- Yes, plastic pipe fittings can be used for irrigation sprinkler systems. Plastic fittings are commonly used in irrigation systems due to their durability, affordability, and resistance to corrosion. They are easy to install, lightweight, and provide a reliable connection between pipes and sprinkler heads.

- Q: Can plastic pipe fittings be used in fire detection systems?

- No, plastic pipe fittings cannot be used in fire detection systems as they do not meet the necessary fire safety standards and are not designed to withstand high temperatures. Metal fittings are required to ensure the integrity and reliability of the system in case of a fire.

- Q: Are plastic pipe fittings resistant to ammonia gas?

- Yes, plastic pipe fittings are generally resistant to ammonia gas.

- Q: Are plastic pipe fittings resistant to hydrostatic pressure?

- Yes, plastic pipe fittings are generally resistant to hydrostatic pressure.

- Q: Can plastic pipe fittings be used for geothermal heating and cooling systems?

- Yes, plastic pipe fittings can be used for geothermal heating and cooling systems. Plastic pipe materials such as high-density polyethylene (HDPE) or cross-linked polyethylene (PEX) are commonly used in geothermal systems due to their durability, flexibility, and resistance to corrosion. Additionally, plastic fittings are easy to install and can withstand the high temperatures and pressures associated with geothermal applications.

- Q: How do you connect plastic pipe fittings to cast iron pipes?

- To connect plastic pipe fittings to cast iron pipes, you can use a transition coupling or a rubber sleeve with stainless steel clamps. The transition coupling is designed to join different types of pipes, while the rubber sleeve with clamps provides a flexible and secure connection. Both options ensure a reliable connection between plastic and cast iron pipes.

- Q: Are plastic pipe fittings resistant to scaling?

- Yes, plastic pipe fittings are generally resistant to scaling.

Send your message to us

Push Fit Plastic Pipe Fittings for Industrial Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords