Plastic Fuel Pipe Fittings PE Reducer Plastic Pipe Fittings for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

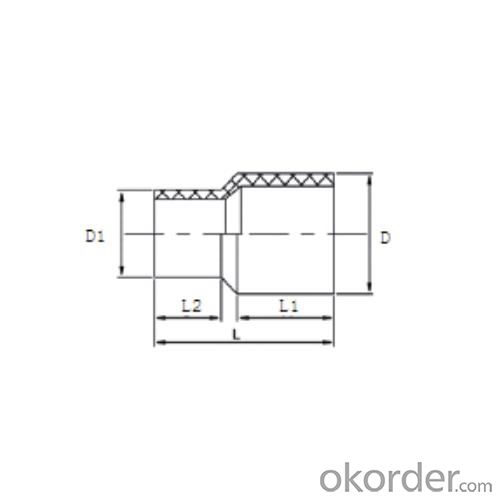

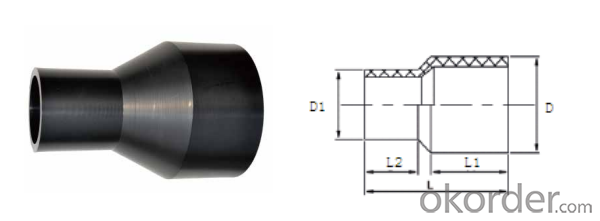

PE Reducer Pipe Fittings for Pipeline System

Pressure grade:

PN≤1.6MPa when DN<400MM

PN≤1.0MPa when DN≥400MM

Size: DN125MM-DN630MM

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Can plastic pipe fittings be used for hydrogen gas storage?

- No, plastic pipe fittings cannot be used for hydrogen gas storage as hydrogen is a highly flammable gas and can permeate through plastic materials, leading to potential leaks and safety hazards.

- Q: Can plastic pipe fittings be used for fluid handling in manufacturing?

- Yes, plastic pipe fittings can be used for fluid handling in manufacturing. Plastic pipe fittings are commonly used in various industries due to their durability, chemical resistance, and ease of installation. They are particularly suitable for handling non-corrosive fluids such as water, chemicals, and gases. However, it is important to consider the specific requirements of the manufacturing process, such as pressure, temperature, and compatibility with the fluid being handled, to ensure the appropriate selection of plastic pipe fittings.

- Q: Can plastic pipe fittings be used for fuel storage systems?

- No, plastic pipe fittings should not be used for fuel storage systems as they are not designed to handle the flammable and corrosive nature of fuels. Metal fittings, specifically those made from materials resistant to corrosion and suitable for fuel storage, should be used instead.

- Q: How do plastic pipe fittings handle thermal expansion and contraction?

- Plastic pipe fittings are designed to handle thermal expansion and contraction through their flexibility and ability to withstand temperature changes. The materials used in plastic pipe fittings have a low coefficient of thermal expansion, meaning they expand and contract less compared to other materials like metal. This allows the fittings to accommodate the expansion and contraction of the pipes without causing damage or leaks. Additionally, plastic pipe fittings often include expansion joints or coupling systems that provide further flexibility and allow for movement without compromising the integrity of the system.

- Q: Are plastic pipe fittings suitable for use in pharmaceutical laboratories?

- No, plastic pipe fittings are not suitable for use in pharmaceutical laboratories.

- Q: Do plastic pipe fittings require any special tools for installation?

- Yes, plastic pipe fittings require special tools for installation. Common tools include pipe cutters, deburring tools, and crimping or compression tools, depending on the type of fitting being used. These tools are necessary to ensure a proper and secure connection between the pipes and fittings, as well as to prevent leaks and maintain the integrity of the plumbing system.

- Q: Are plastic pipe fittings easy to disassemble and reassemble?

- Yes, plastic pipe fittings are generally easy to disassemble and reassemble. They are designed to be easily connected and disconnected, allowing for quick and convenient assembly or disassembly of plumbing systems.

- Q: Are plastic pipe fittings resistant to earthquakes?

- Plastic pipe fittings can vary in their resistance to earthquakes depending on their material and design. Some plastic materials, such as PVC, can be relatively brittle and prone to cracking under seismic activity. However, there are also more resilient plastic materials, like high-density polyethylene (HDPE), which offer better resistance to earthquakes due to their flexibility and ability to absorb vibrations. Additionally, the design and installation of the fittings can also play a significant role in their earthquake resistance. So, while plastic pipe fittings can provide some level of resistance, it is essential to consider the specific material, design, and installation methods to ensure their effectiveness in seismic events.

- Q: Are plastic pipe fittings resistant to electromagnetic interference?

- No, plastic pipe fittings are not inherently resistant to electromagnetic interference.

- Q: Can plastic pipe fittings be used in fire escape systems?

- No, plastic pipe fittings cannot be used in fire escape systems. Fire escape systems require materials that are resistant to high temperatures and can withstand the effects of fire. Plastic pipe fittings are not designed to meet these safety requirements and can pose a significant risk in the event of a fire.

Send your message to us

Plastic Fuel Pipe Fittings PE Reducer Plastic Pipe Fittings for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords