PLASTIC GRANULE CUTTER FPB-200 applicable to composite plastic brace cutting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Application: plastic pelletize

Place of Origin: Zhejiang, China (Mainland)

Brand Name: GT

Model Number: <SPAN class=attr-value title=FPB-140/150/180/200>FPB-140/150/180/200

Saw Blade Diameter: 2-3mm

Power(W): 3-4kw

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | wooden case |

|---|---|

| Delivery Detail: | 30-45days |

<STYLE type=text/css> .richtext [data-maya] { width: 750px; font-size:14px; }

Specifications

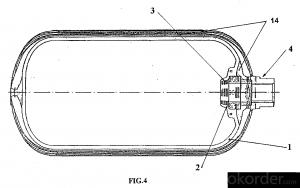

plastic grain cutter

plastic granule cutter

plastic pellet cutter

Product Description

Rolling blade of cutting grain : Φ140mm × Φ140mm,Φ200mm× Φ 200(mm)

Material of rolling blade : Alloy steel.

Max. Prilling capacity : 200-600kg/h

Motor power : 3-4kw

Speed control :electromagnetic

Weight :500kg

- Q: Can ultrasonic plastic cutting cut 30 mm boards?

- Ultrasonic cutting does not require sharp edges, nor does it require great pressure and will not cause breakage or breakage of the material to be cut.Because the cutter is doing ultrasonic vibration, the friction resistance is very small, and the cutting material is not easy to stick on the blade. This is particularly effective for viscous and elastic materials, frozen materials, such as food, rubber, etc., or for cutting under pressure.

- Q: How can I cut the polyurethane foam board?

- Usage methodStep 1: shake it 15-30 times before use, up and down;The second step: before construction, clean the filling area and spray it with water;The third step: turn the tank upside down and rotate it at the nozzle of the gun / hose. Turn the spray gun flow valve adjustment counterclockwise;The fourth step: spray from bottom to top, spray volume to 80% of the required volume of filling (tube filling volume of 2/3);The fifth step: ten minutes after the beginning of dry surface, one hour after curing, further processing;The sixth step: cured foam, can use a sharp knife to remove excess parts, and then in the surface with cement mortar, paint or silica gel processing.

- Q: What about cutting a piece of plastic into a circle?

- With a suitable radius of the bamboo bar, while nailing a nail or a needle, a head in the center of the circle, and then draw a circle like push, understand the other root, pay attention to push down when the point is good, turn a few laps better

- Q: Ask you great God, cutting PVC pipe is good with woodworking saw blade, or saw the blade of aluminum? Woodworking saw blade is 60 teeth, the incision will not be smooth enough? Also, the saw blade is 120 teeth. Thank you

- 10 inch 60 tooth woodworking saw blade is enough, PVC pipe to be so smooth, cut no use ah, do not collapse side on the line

- Q: Cut PVC plastic, what saw blade?

- Should be able to use large right aluminum alloy saw blade 405x2.8x25.4x160T

- Q: What can be used to cut it? What is it with special cement and water?

- PVC transparent hard, and marble with push table saws cutting machine cutting. PVC special glue can bond.

- Q: What kind of saw blade is used for cutting plastics?

- Alloy saw blade, the family good Wald cheap, quality is guaranteed

- Q: How to cut foam and sponge?

- If you use a hot wire to cut, can be an easy job to do to implement, just like a knife like tofu, if the speed master well will not affect other parts of the shape, therefore, we use the hot cutting processing method of foam and sponge is a kind of ideal method (factory by hot plastic injection method is another matter).

- Q: How do I cut square holes on such a plastic board (acrylic plate)? Asking for cutting out the square.

- AskI saw No. I have an electric drill. Do you have a corresponding milling cutter?.Chasing the answerThe working principle of the milling cutter is rotary cutting. It can not process the four right angles that you require. The radius, the arc angle and the angle of the milling cutters can appear on the corners.

- Q: What tools are used for cutting PVC boards? Can electric saws be used in woodworking?

- PVC resin has the advantages of plastic products is generally difficult to burn, abrasion resistance, chemical resistance, low leakage, good gas vapor. In addition, comprehensive mechanical energy, products transparent, electrical insulation, insulation, noise elimination, shock elimination, or better, is the most superior price than the general type of material. The defect is thermal stability and shock resistance is poor, whether it is hard or soft, PVC is easy to produce brittle during use. General PVC is not containing the relevant national standards allow the use of two (2 - ethylhexyl) adipate plasticizer (DEHA), DEHA in the high temperature (over 100 degrees Celsius) easily released, after contact with human health hazard. Because PVC is a hard plastic, to make it soft, a large amount of plasticizers must be added. Plasticizers are easy to release in a heated environment. If you are using DEHA, it will interfere with the human endocrine, cause women to breast cancer, birth defects, reduce the number of male sperm, or even mental disorders.

Send your message to us

PLASTIC GRANULE CUTTER FPB-200 applicable to composite plastic brace cutting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords