Film Automatic Crushing&Loading Force Feeder Pelletizing Line LDA-SJP-90

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

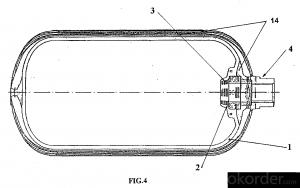

Features of Film Automatic Crushing&Loading Force Feeder Pelletizing Line LDA-SJP-90

Automatically crushing and baiting through the power of blower. It enables crushing, baiting and extruding all in one(Hydraulic screen changer and PLC control system are optional). Time and power saving, highly automatic and improve the work efficiency greatly.

Different screw design can produce different plastics.

If matched with different die heads and auxiliary machines,it also can make plastic production.

Features: stable quality, high efficiency, high output, wide applicable range, long serving life.

Use:of Film Automatic Crushing&Loading Force Feeder Pelletizing Line LDA-SJP-90

This machine is suitable for recycling PE, PP, PA membranes and loose materials.motor:30kw output:100kg/h

Packaging & Delivery

| Packaging Details: | Packed in wooden case,side screw force feeder pelletizing line |

|---|---|

| Delivery Detail: | Delivery Within 30-45 Working Days,side screw force feeder pelle |

Kindly feel free to contact with me if you need more detail informations.

And if convenience for you,welcome to visit our factory to know more about our machine.

- Q: How do you cut the plastic plate neatly?

- 3 mm thick plexiglass plate, the need to neatly cut into blocks, with the saw too cumbersome, and can not cut with the blade, very distressed. Masters, help. But organic glass is different from ordinary glass. It has a certain toughness. There's nothing I can do about the glass cutter.

- Q: How to make sure the plastic bag is fast on the hot machine?

- Thickness is a big center of gravity that limits the cutting machine, and again the size of the finished bag.Many kinds of cutting machine, size cutting machine, such as size of 5*10cm OPP bag cutting machine is usually very small, the operation is more in line with specificationsSo, this is an uncertain factorWith the same machine production of different sizes of specifications, yield will naturally vary.

- Q: Twenty-fivePlastic sheet supplier plate is a unified specification (1m*2m*1.5mm) of the board, I need batch cut / cut into rectangular plate (80CM*2CM), I should find the cutting process taking processing? Or plastic plate manufacturers can directly produce according to the size of it?

- Suggest laser cutting,Can also use 120 teeth of alloy saw blade cutting, faster

- Q: Plastic pipe production line cutting process dust?

- In fact, no matter what the cutting process will produce dust, but there are (PM20 below) dust particles can not be seen with the naked eye.

- Q: Cut PVC plastic, what saw blade?

- Should be able to use large right aluminum alloy saw blade 405x2.8x25.4x160T

- Q: I am a novice, recently wanted to do a cutting equipment, material for LCP material, I would like to ask you predecessors, how to cut to ensure that after cutting the edge of plastic without burr? Thank you

- I said: if you cut smaller, I suggest you use a heating block in the oblique mouth, cut off the heating of the premise, which can reduce the burr or burr.

- Q: Multi power supply for electric wire cutting plastics

- 1KW (a broken electric wire interception can, with enough length) 1kW pressure regulator 220V voltage adjustment, into the 220V 36V double coil 200W of a transformer, two 36V resistor wire, adjust the voltage and resistance of micro red, hot plastic incision should be burnt black. Everything is in the test. Wish you success!

- Q: Wallpaper knife tried, the effect is not very good, I do not know what tips can be cut foam, as far as possible, less ball ball!It's that kind of thinner foam, such as styrofoam in a computer boxThank you

- You can use electric wire cutting.The first, first bidirectional silicon controlled voltage regulating circuit boards can be disassembled by the waste light regulating desk lamp or made by themselves;Second, first suitable transformer, primary 220V, secondary 12-36v power can be, can not be too small to secondary rated current more than 2A is appropriate, I used a 220v/24v, 100W, the secondary current is about 4A, the secondary current point is conducive to the use of electric heating wire thicker, tensile point. The voltage regulating circuit and transformer mounted on a wooden box in 220V, power regulating circuit, whose output is connected to the transformer 220V side, transformer secondary is connected with the two terminals or rose as a low voltage output.Third, heating wire, electric wire available waste, according to the transformer secondary current selection of suitable electric wire, cutting material size according to the appropriate length of interception of vertical tension (can be fixed according to their own circumstances such as a stent), both ends of the transformer secondary wiring to, from low to high output voltage can be cut to the right.Benefits: electric wire can be selected according to the length of processing materials, adjust the voltage, so that the temperature is suitable for cutting can be, - it should not be too high, so as to avoid electric wire break

- Q: I bought a tidying up box for my hamster DIY cage, but hard plastic is difficult to cut ~ ~ what can be better to cut open hard plastic?

- Cutting is usually done using a cutting machine.Classification of cutting machinesCutting machine is divided from cutting material, divided into metal material cutting machine and non-metallic material cutting machine.Metal cutting machine for flame cutting machine, plasma cutting machine, laser cutting machine, cutting machine etc.;The non-metallic material cutting machine is mainly cutter cutting machine.Non-metallic material cutting machineIn general, non metal industry is meticulous, like a stone cutting stone cutting machine, water cutting machine, saw cutting machine; cutting cloth, chemical fiber and plastic products for laser cutting machines, blade type cutting machine.Household cutting machineThe majority of electric cutters used in the general family are called multi-functional hand cutters. For the cutting of different materials, only the corresponding blades of different materials can be used. For brands, the doctor's brand is very useful, of course, the price is slightly expensive.Be carefulPay attention to safety. Read the instructions carefully.

- Q: How do you cut the plastic board and cut the 4 mm plastic hard board?

- The plastic is made of synthetic or condensation polymerization with monomer raw materials, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives, it is the main component of synthetic resin.Plastics are also classified as ubiquitous plastics and engineering plastics, mainly for their wide range of uses. For example, PE and PP are inexpensive and can be manufactured on a wide range of machines. Engineering plastics are more expensive, but the material stability and physical properties are much better. Generally speaking, they have two characteristics: rigidity and toughness.

Send your message to us

Film Automatic Crushing&Loading Force Feeder Pelletizing Line LDA-SJP-90

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords