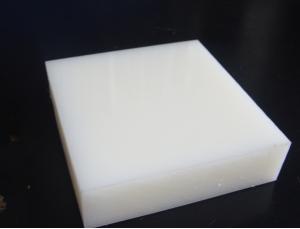

RTM Mould For RTM Process

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction of RTM Mould

On the basis oftraditional technics, Hengjixing together with foreign professions developed aquick moulding process with the foreign epoxy gel coat & resin at the endof 2001.

2.Characteristics

On the basis oftraditional technics, Hengjixing together with foreign professions developed aquick moulding process with the foreign epoxy gel coat & resin at the endof 2001. 15 days were needed to make a mould, but now 5 days are OK with suchprocess.

3.Application

- High intensity Resist flection: 70-80 N/mm, Resist compression: 115-120 N/mm

- No shrinkage

- High hardness Shore hardnessD 85-90

- High temperature resistant 115℃-120℃

- Short machining period, just need onethird working days of past to develop the following products successfully

Ø Auto (Hummer) bumper mold (total 5 pics mouldassembled)

Ø Radar cover mold for Beijing University of Aeronauticsand Astronautics (BUAA)

Ø Teaching molds for Nanjing University of Aeronauticsand Astronautics (NUAA)

Ø Bumper, Pedal mould for STERY Auto

Ø NMR bed board, carbon fiber board

Ø RTM mould of cello case

Ø RTM water tank panel moulds for south-east Asiancustomers (Pneumatic operation)

Ø Impeller mold

4.FAQ

Packaging & Delivery

Packaging Details: | woven belt |

Delivery Detail: | 5-7 days,according to the order |

Send your message to us

RTM Mould For RTM Process

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords