FRP PIPE FILAMENT WINDING MACHINE DN500-1000

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GENERAL INTRODUCTION

Equipment Description:

The product and process is strictly according to the advanced standard and using digital control system. The Final product is for different medium of different kind of GRP pipes

1.2 Process Description:

1.2.1 Lining Making:

Firstly paste the de-molding agent on the mandrels and then wrap film (PET or PP) on it. thereafter, the first plies of fiberglass reinforcements are winded and retain a very high percentage of corrosion resistant resin by resin spraying device. This operation enables a fully impermeable wall to be obtained with a high resistance to chemicals.

1.2.2 Filament Winding with sanding:

The structural part of the pipe is made by the filament winding of continuous fiberglass roving impregnated with resin. The pitch of the winding spiral and, thereby, the angle formed between the rovings and the axis of the pipe are determined during the design work and depends on the stresses to be withstood. At the same time as filament winding is taking place. The silica sand is to be included in the pipe layer from bottom with terry line cloth.

1.2.3 External Curing

To prevent the resin from dropping, the curing operation is carried out while the pipe is rotating in its own axis. Curing of FRP pipe is made by special infrared heating device.

1.2.4 De-molding

The pipe is extracted from the mandrel; this operation takes place in a special working station controlled by a hydraulic system which allows to automatically carrying out the different working phases.

1.2.7 3.Application

Design Data:

Winding angle 45-90 degree,

Control mode Manual / Semi automatic / Automatic

Precision of lining up filament ±1 mm

Filament feed speed 85m/min max.

Winding type cross and hoop direction

Resin type Unsaturated polyester

Curing IR

Filament Creel Tension adjustable

Digitalized display precision: 0.01mm,

Sand adding thickens 15mm/layer max.,

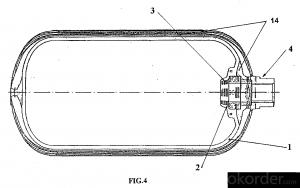

1.2.8 Finished products Specification:

Effective Length 12 meters

Diameter 500~1000mm

Output 84 km /year of Dia.600mm pipe (6 bar and SN=5000)

1.2.9 Raw Material Resin

Isopthalic resin Viscosity=3.5~4 poises

Reactivity = medium

Good chemical inertness coupled to high mechanical strength in the laminate

Urthopthalic resin Viscosity=4~5 poises

Reactivity = medium to high

Good mechanical strength in the laminate, suit for transport any kind of water

Vinyl ester Resin Be suitable for hot high corrosive product to be handled and conveyed.

Glass Reinforcement

BOPET or BOPP film 10~30um thickness, 50mm width, for fist lining layer liner

Helpful for demoulding process

E Glass tape Veil type, for lining layer

200mm width, 30~35 gsm

E Glass CSM tape Mat type, for second layer of liner

200mm width, 375~450gsm

E Glass direct roving 2400 tex or 4800 tex

Auxiliary Raw Material

Accelerator solution of cobalt naphtenate in styrene

Inhibitor 10% solution of ter-tutyl-catechol in styrene

Silica sand provide stiffness for pipe and save production cost

1.2.10 FAQ

Manpower

Material Supply System 1 person / per shift

Lining Machine 2 persons / per shift

Filament Winding System 3 person / per shift

Curing System (External Curing) 1 persons / per shift

De-molding System 2 persons / per shift

Pipe Trimming System 2 persons / per shift

Hydrostatic Testing Machine 3 persons / per shift

Send your message to us

FRP PIPE FILAMENT WINDING MACHINE DN500-1000

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords