Plastic Granulator for PET Flakes Granulation Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Raw material & Final product:

Raw material & formulation | PET materials |

Final product & Output capacity | 400kg/h |

Description of final product | 1. PET granules |

2. Work condition:

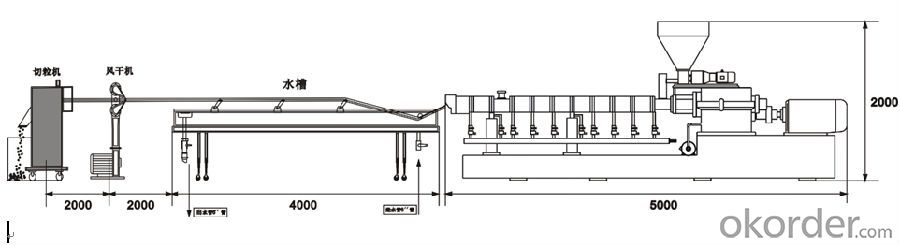

Warehouse/Workshop | Dimension (M*M*M): 15(L)×3(W)×3(H); If workshop is small, turn the machine around. |

Power supply & Installation power | 3-phase, 380 V, 50 Hz; (do as customer's request) |

Wire/cables(provide by customer) | Wires/cables from power supply to control cabinet of this production line; all electrical cables from control cabinet to each machine. |

Water supply hose/pipe(provide by customer) | Water supply to machines and pools |

3. Energy consumption:

Installation power | 210Kw ( Actual Consumption 180Kw ) |

Water supply | Consumption: ~1 tons per hour cycling water. Pressure: 0.6Mpa |

Manpower | 1 Persons |

Equipment List

Item | Name | Specification | Qty | Total Price |

1 | Parallel Extruder JH75 | 132+61Kw | 1 pc. |

USD 64200 FOB Shanghai CE Standard

|

2 | Hydraulic Screen Exchanger | 2.2Kw | 1 pc. | |

3 | Head | / | ||

4 | Water Cooling Slot | / | 1 pc. | |

5 | Air Blower Dryer | 1.5Kw | 1 pc. | |

6 | Granulator | 7.5Kw | 1 pc. | |

7 | Electrical Cabine | / | 1 pc. |

Business Term

DELIVERY | : | FOB Shanghai, |

PRICE | : | 64200 USD |

DELIVERY TIME | : | 30 Days |

OFFER VALIDITY | : | 30 Days |

TERMS OF PAYMENT | : | 30% of down-payment by T/T. Balance 70% T/T before delivery |

WARRANTY | : | Mechanical parts & Electrical parts : 12 months for parts considered by the manufacturer to be defective. |

INSTALLATION | : | Two persons are needed for commissioning; The buyer afford buy and back round ticket, accommodation, and 50usd allowance per person. It takes 10days installation. |

- Q: Comparison of swing granulator, high-speed granulator, one-step granulator difference?

- Dry granulation can be added powder, additives, wet add powder, it will not work.

- Q: How should maintain plastic granulator

- Always clean the plastic residue in the case so as not to use the card machine. Clean with alcohol or gasoline. Keep lubrication of relative movement parts.

- Q: How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q: How about the granulator?

- Our company absorb domestic and foreign advanced technology and experience, in strict accordance with the national requirements of GMP design, development, production, installation and service in one, and in strict accordance with the ISO9001 international quality system standards implementation, to ensure product quality.

- Q: Plastic granulator feed roller does not turn is what reason

- You see whether the gear or chain is driven, if it is a positive gear or the chain is broken.

- Q: How much will it cost to invest in the recycled plastic particle production line?

- Price: 330000 yuanModel / specification: LGHB-ZL220Power: 75Product Name: plastic granule machine, plastic granulatorApplicable materials: PE, PP, BOPP, HDPE, PA, CPP, PS, PVC and so onCapacity: 100-500After sale service: 1 yearsProduct parameter:1. output: 100-500 kg / h2. applicable materials: PE, PP, BOPP, HDPE, PA, CPP, PS, PVC, etc.3., the latest design of pneumatic particle cutting device, plastic particles more substantial, plump.

- Q: how much the price, I hope to know a friend told me Oh, thank you ah!

- The new waste plastics Ziyang Universiade social concern for the regeneration of granular plastic equipment, are more and more customers, the use of mechanical regeneration granulation, waste plastics recycling is a new way of development. Low investment, fast income, no pollution, is the ideal project for family investment and small and medium enterprises to change their production line, without investment risk. All kinds of plastic (plastic, woven bags, convenient bags, beverage bottles, plastic tubs, old sandals etc.) can be processed into plastic particles, the particles are made from cleaning to mechanical operation.

- Q: The difference between the whole machine, granulating machine, granulating machine of the three English translation?

- The whole machine is mainly used in pharmaceutical industry, granulation after drying agglomerated particles, according to the technical requirement of finishing qualified to uniform particles, mixing and tabletting machine. Widely used in raw materials, chemicals, food and other industries. Principle: the boiling granulator pellet out of dry particles by lifting the feeder switch into hopper, granulator opening valve, will join particles granulator; through the cavity of the rotary granulating knives, the material by the impact, extrusion, shear, discharged through the sieve hole, the cylinder to flow to the container.

- Q: How to calculate the plastic granulator gear ratio, to control the length of the particle

- Main parameters: diameter of traction roller. Cutter diameter and cutter tooth number. Back gear ratio. Let's put these parameters together. I dare not speak too much

- Q: Dry granulator and wet granulation machine what is the difference

- The so-called wet granulation is generally back to the use of materials, granulation is not afraid of a little moisture

Send your message to us

Plastic Granulator for PET Flakes Granulation Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches