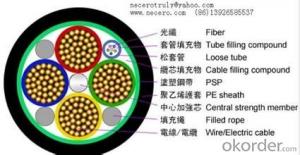

Eccentric water-satomizing plastic granulation xlpe cable material compound line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GS65/150 Eccentric water-satomizing plastic granulation xlpe cable material compound line

Parallel corotating twin screw extruders have excellent mixing performance,good self cleaning

performance and flexible modular configuration characteristics which make them suitable for

processing different types of material systems,and are extensively used in fields of polymer

processing ,foodstuff processing and chemical products, especially for various high molecular

materials. In most cases ,parallel corotating twin screw extruders are used as mixing equipments .

ln processing high molecular materials,the modification process and master batch preparation of

polyolefin materials and engineering plastics require sufficient and intensive mixing,which differs

depending on material systems, Excellent equipment performance,reasonable mixing process,

advanced combination technique and rich processing experience are the key factors determining

the success and efficiency of mixing.

Model Parameter | GS-20 | GS-35 | GS-50 | GS-65 | GS-75 | GS-95 |

Main motor | 4 | 45-22 | 37-65 | 45-75 | 75-160 | 132-250 |

Screw diameter | 21 | 35.6 | 50.5 | 62.4 | 71 | 93 |

L/D | 28-40 | 28-48 | 28-64 | 28-64 | 28-64 | 28-64 |

Rotate speed(rpm) | 0-600 | 0-600 | 0-600 | 0-600 | 0-600 | 0-600 |

Screw material | bi-metal | bi-metal | bi-metal | bi-metal | bi-metal | bi-metal |

Screw hardness | HRC65 | HRC65 | HRC65 | HRC65 | HRC65 | HRC65 |

Shaft core material | 40CrNiMoA | 40CrNiMoA | 40CrNiMoA | 40CrNiMoA | 40CrNiMoA | 40CrNiMoA |

Before-sale

@Introduce products and applications detain

@Recommend suitable solution

@Provide with reference in formation

@Offer lab for test

During manufacturing

@Provide with layout and engineering conditions

@Inform the project processing status

@Offer other documents

After-sale

@Provide with installation ,commissioning and training

@Register and record customer information

@Offer spare parts

@Provide with necessary technical support for new application

@Visit customer regularly and correct information

- Q: Is environmental protection approved for plastic granulation?

- A project does not require EIA, and the EIA is a report or a report form, according to the State Environmental Protection Department's "construction project environmental impact assessment classified management list" of the coming.

- Q: How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q: How about the granulator?

- Our company absorb domestic and foreign advanced technology and experience, in strict accordance with the national requirements of GMP design, development, production, installation and service in one, and in strict accordance with the ISO9001 international quality system standards implementation, to ensure product quality.

- Q: Plastic granulator feed roller does not turn is what reason

- There is also a two axis of its own teeth rotation, it may be broken bearings.

- Q: how about the market demand, which kinds of particles are usually divided? Which particle has a higher profit margin?

- Grinder, cleaning machine, extrusion machine, granulator, a few hundred thousand million yuan - set. I did it. Raw materials are LDPE, HDPE, PP and so on

- Q: What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

- Q: how much the price, I hope to know a friend told me Oh, thank you ah!

- We are Guangdong Province Quality Inspection Association unit, we follow the IS9001 quality control system requirements, establish a complete and standardized internal technical standards and quality control procedures, from pre-sales service to product design, manufacturing and service process control point, to create a full range of star delta product quality, we are specialized in plastic granulating machine R & D, manufacturing and service of a professional engineering team and staff, provide a solid guarantee for the customer confidence. ?Our detailed models include: plastic granulator pumping machine waste plastic granulator small granulator engineering plastic granulator film plastic granulator recycling granulator plastic masterbatch granulator granulation production non-woven granulator magnet powder granulator granulator wind ring eager water ring inHot cutting granulator Color Masterbatch granulator ceramic powder machine LCP granulator experimental plastic granulator waste bags plastic granulator granulator; business scope: granulator project - PE, PP, PVC, PVB, ABS, HIPS, PBT, PA, PU, EVA, PC, PS, AS, PMMA, POM, PET, color masterbatch... Plastic color mixing rod machine, modified plastics granulator, plastic alloy granulator; one or two, three grade plastic recycling machine configuration; granulating machine parts etc.;

- Q: The difference between the whole machine, granulating machine, granulating machine of the three English translation?

- The granulator is a kind of forming machine which can make material into a specific shape. Widely used in chemical, petrochemical, pharmaceutical, food, building materials, mining and metallurgy, environmental protection, printing and dyeing, ceramics, rubber, plastics and other fields. According to the structure and working principle and divided into CF type rotary belt type condensing granulator flat twin screw extruder drying drum roll production machine dry granulating machine (referred to as the roll granulator granulator) on tooth disc vacuum condensation granulator. The granulating mechanism has the advantages of quick granulation and good effect. The filter screen for designing special holes is carefully screened, and the friction filter rod can crush, sieve and filter the solid particles, and is widely used in the pharmaceutical, chemical and food industries. Instead of swing granulator, the utility model is a new generation of granular equipment.

- Q: How to calculate the plastic granulator gear ratio, to control the length of the particle

- Main parameters: diameter of traction roller. Cutter diameter and cutter tooth number. Back gear ratio. Let's put these parameters together. I dare not speak too much

- Q: What plastic particles are used for wire injection? How much would you like to invest in a plastic pelleting plant?

- Wire is generally used PVC majority, there are some cable, fiber cable with HDPE, LDPE, EVA and so on.

Send your message to us

Eccentric water-satomizing plastic granulation xlpe cable material compound line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches