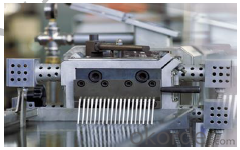

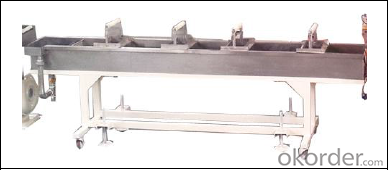

Plastic Granulator for Parallel Twin Screw Extruder Pelletizing Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Parallel Twin Screw Extruder Pelletizing Machine Line Characteristics:

Capacity: 50-500 kg per hour

ABB or Simens motor, Omron or Simens electrical parts

Material: Carbon steel and stainless steel

CE Standard; Provide Turn Key Solution.

Optional design for customer: PLC control, no net filter extruding, electrical parts brand, etc.

Parallel Twin Screw Extruder Pelletizing Machine Line Pelletizing Type:

Hot face cutting granulator

Water ring cutting granulator

Water cooling granulator

Other pelletizing type

Parallel Twin Screw Extruder Pelletizing Machine Line Application:

PP nonwovens recycling granulator

PE PET flakes recycling granulator

Filling material pelletizing, master batch pelletizing

Recycle PP, PE pipe pelletizing

Parallel Twin Screw Extruder Pelletizing Machine Series:

Model | SJ-35 | SJ-50 | SJ-65 | SJ-75 | SJ-95 |

Screw diameter(mm) | 35.6 | 50.5 | 62.4 | 70.5 | 93 |

L/D | 32,36,40,44,48 | ||||

Main motor power(kw) | 15 | 37 | 55 | 90 | 150 |

Screw rotation speed(r/min) | 600 | 600 | 600 | 600 | 600 |

Torque | 115 | 415 | 680 | 995 | 2380 |

Plasticization capability(kg/h) | 50-80 | 80-150 | 150-300 | 250-500 | 450-800 |

- Q: Comparison of swing granulator, high-speed granulator, one-step granulator difference?

- General plastic and water will degrade the performance of plastic degradation will make significant decline, affect the product performance, so the new material is generally not wet, extrusion is to make the plastic particle drying.

- Q: Waste plastics granulation EIA Report Sample

- The book is very thick and the EIA form is very simpleYou directly find qualified to do the EIA, for you to doAre you planning to apply for the quota for imported plastic waste?

- Q: Plastic granulator feed roller does not turn is what reason

- You see whether the gear or chain is driven, if it is a positive gear or the chain is broken.

- Q: how about the market demand, which kinds of particles are usually divided? Which particle has a higher profit margin?

- It's too late! It's hard to collect scrap!

- Q: What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

- Q: How much will it cost to invest in the recycled plastic particle production line?

- Price: 330000 yuanModel / specification: LGHB-ZL220Power: 75Product Name: plastic granule machine, plastic granulatorApplicable materials: PE, PP, BOPP, HDPE, PA, CPP, PS, PVC and so onCapacity: 100-500After sale service: 1 yearsProduct parameter:1. output: 100-500 kg / h2. applicable materials: PE, PP, BOPP, HDPE, PA, CPP, PS, PVC, etc.3., the latest design of pneumatic particle cutting device, plastic particles more substantial, plump.

- Q: The difference between the whole machine, granulating machine, granulating machine of the three English translation?

- The whole machine is mainly used in pharmaceutical industry, granulation after drying agglomerated particles, according to the technical requirement of finishing qualified to uniform particles, mixing and tabletting machine. Widely used in raw materials, chemicals, food and other industries. Principle: the boiling granulator pellet out of dry particles by lifting the feeder switch into hopper, granulator opening valve, will join particles granulator; through the cavity of the rotary granulating knives, the material by the impact, extrusion, shear, discharged through the sieve hole, the cylinder to flow to the container.

- Q: How to calculate the plastic granulator gear ratio, to control the length of the particle

- Main parameters: diameter of traction roller. Cutter diameter and cutter tooth number. Back gear ratio. Let's put these parameters together. I dare not speak too much

- Q: May I ask who knows the plastic granulator manufacturers contact ~ figure

- China is the same, who knows who ah?. Otherwise, better contact

- Q: How can the granulator recycle the plastic bottle?

- Well, what is the sorting process of the plastic granulator?A typical process in which the discarded bottles will be sorted first on the basis of color and size sometimes. Once sorted, they need to be washed away; however, the washing machine, while in a piece, is not the most advantageous way. Therefore, to facilitate the washing process, the bottle is likely to be broken down into small pieces. Plastic granulator, plastic grinding machine can be used to do work, such as Jordan to reduce the manufacture of solutions. They let a shredder break down into smaller sizes and then send it to the cleaning station for a wide variety of plastic and PET containers. Check out some plastic crush videos. Once the bottle is torn and a suitable size is washed, they are not yet ready for processing into other goods.

Send your message to us

Plastic Granulator for Parallel Twin Screw Extruder Pelletizing Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords