Plastic Granulation Machine Line for Type 65

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Raw material & Final product:

Raw material & formulation | Plastic flakes |

Final product & Output capacity | 300kg/h |

Description of final product | 1. plastic granules |

Work condition:

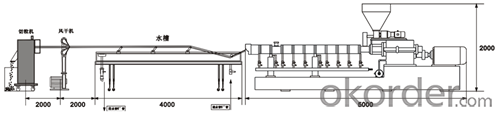

Warehouse/Workshop | Dimension (M*M*M): 15(L)×3(W)×3(H); If workshop is small, turn the machine around. |

Power supply & Installation power | 3-phase, 380 V, 50 Hz; (do as customer's request) |

Wire/cables(provide by customer) | Wires/cables from power supply to control cabinet of this production line; all electrical cables from control cabinet to each machine. |

Water supply hose/pipe(provide by customer) | Water supply to machines and pools |

Energy consumption:

Installation power | 100Kw ( Actual Consumption 60Kw ) |

Water supply | Consumption: ~1 tons per hour cycling water. Pressure: 0.6Mpa |

Manpower | 1 Persons |

Equipment List

Item | Name | Specification | Qty | Total Price |

1 | Parallel Extruder JH65 | 55+40Kw | 1 pc. |

USD 41000 FOB Shanghai CE Standard

|

2 | Hydraulic Screen Exchanger | 2.2Kw | 1 pc. | |

3 | Head | / | ||

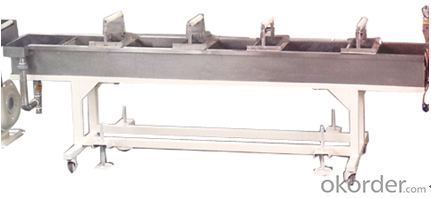

4 | Water Cooling Slot | / | 1 pc. | |

5 | Air Blower Dryer | 1.5Kw | 1 pc. | |

6 | Granulator | 7.5Kw | 1 pc. | |

7 | Electrical Cabine | / | 1 pc. |

Business Term

DELIVERY | : | FOB Shanghai, |

PRICE | : | 41000 USD |

DELIVERY TIME | : | 30 Days |

OFFER VALIDITY | : | 30 Days |

TERMS OF PAYMENT | : | 30% of down-payment by T/T. Balance 70% T/T before delivery |

WARRANTY | : | Mechanical parts & Electrical parts : 12 months for parts considered by the manufacturer to be defective. |

INSTALLATION | : | Two persons are needed for commissioning; The buyer afford buy and back round ticket, accommodation, and 50usd allowance per person. It takes 10days installation. |

- Q: Comparison of swing granulator, high-speed granulator, one-step granulator difference?

- Dry granulation can be added powder, additives, wet add powder, it will not work.

- Q: How should maintain plastic granulator

- The moving knife and the fixed knife sharpness and clearance check. Wear and change of traction roller.

- Q: Is environmental protection approved for plastic granulation?

- A project does not require EIA, and the EIA is a report or a report form, according to the State Environmental Protection Department's "construction project environmental impact assessment classified management list" of the coming.

- Q: How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q: how about the market demand, which kinds of particles are usually divided? Which particle has a higher profit margin?

- First, the salesman's task is according to customer requirements and designers to cooperate with the printing program, and confirmed by the customer. Raw materials for customers are generally: 1, Wen Dang (not necessarily standard). 2, in kind. 3 oral or written product description. To be as detailed as possible, if the conditions, so that customers and designers face to face, easier to complete the design faster. Two, according to the salesman: 1, the customer has confirmed the program (usually a single version of the design). 2, production quantity and economic benefits. 3, printing machines and other production equipment requirements (first on the boot). Process for production and imposition jointly determine the production department, business department, and the scheme to allow the designer to perform. Three, according to the technical scheme designer imposition, film output, proofing proofing confirmation print version of the housing.

- Q: What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

- Q: How much will it cost to invest in the recycled plastic particle production line?

- 4. more efficient cutting and compacting machine to ensure high output of granulator equipment and low energy consumption.5., from Europe's leading design of dehydration machines and vibrating screen, greatly reducing the energy consumption of equipment,And improve the efficiency of granulator equipment.6., the new granulator has: reasonable configuration, smooth operation, low noise, energy saving, high yield and so on7. certification of CE and ISO9001 professional organizations.

- Q: how much the price, I hope to know a friend told me Oh, thank you ah!

- We are Guangdong Province Quality Inspection Association unit, we follow the IS9001 quality control system requirements, establish a complete and standardized internal technical standards and quality control procedures, from pre-sales service to product design, manufacturing and service process control point, to create a full range of star delta product quality, we are specialized in plastic granulating machine R & D, manufacturing and service of a professional engineering team and staff, provide a solid guarantee for the customer confidence. ?Our detailed models include: plastic granulator pumping machine waste plastic granulator small granulator engineering plastic granulator film plastic granulator recycling granulator plastic masterbatch granulator granulation production non-woven granulator magnet powder granulator granulator wind ring eager water ring inHot cutting granulator Color Masterbatch granulator ceramic powder machine LCP granulator experimental plastic granulator waste bags plastic granulator granulator; business scope: granulator project - PE, PP, PVC, PVB, ABS, HIPS, PBT, PA, PU, EVA, PC, PS, AS, PMMA, POM, PET, color masterbatch... Plastic color mixing rod machine, modified plastics granulator, plastic alloy granulator; one or two, three grade plastic recycling machine configuration; granulating machine parts etc.;

- Q: How to calculate the plastic granulator gear ratio, to control the length of the particle

- Main parameters: diameter of traction roller. Cutter diameter and cutter tooth number. Back gear ratio. Let's put these parameters together. I dare not speak too much

- Q: How can the granulator recycle the plastic bottle?

- How much resources can we save by recycling? How much does it cost us? When you throw away a plastic bottle, do you think of those problems? At the same time you throw away the plastic bottles, you are also polluting the environment, but also a great waste of behavior. We can not underestimate a plastic bottle, do not look at it inconspicuous, in fact, it has become an indispensable product in our daily life.All our daily use of water, soda water, dishwashing liquid, and various other plastic bottles are made from Teraphthalate, a polyethylene plastic compound or PET. And all such PET bottles have many uses, many people are not aware of. However, prior to any other product can be manufactured from our discarded bottles, they must be cleaned through an elaborate sorting process, chopped, and, in some cases, re washed, dried and pelletized. And there are many ways to deal with the basis of processing facilities, mainly plastic. Therefore, with the development of science and technology, the plastic granulator has come into being, and the plastic granulator can recycle the plastic bottles we discarded, according to the sorting process.

Send your message to us

Plastic Granulation Machine Line for Type 65

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords