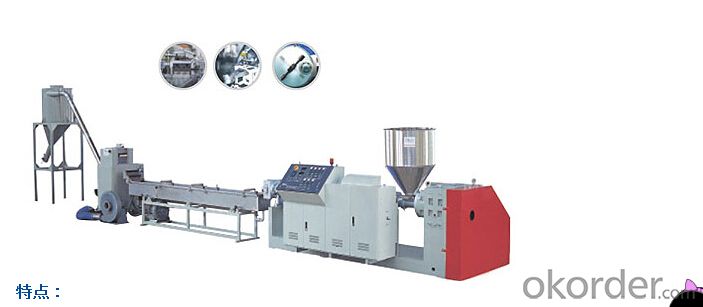

CMAX Serious Single Screw Pelletizing Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

waste plastic pelletizing line

is used to pelletize waste PP,PE film, etc.

With capacity from 18-1200kg/h.

plastic pelletizerwaste plastic pelletizing line

is used to pelletize waste PP,PE film, etc.

With capacity from 18-1200kg/h.

plastic pelletizerwaste plastic pelletizing line

is used to pelletize waste PP,PE film, etc.

1.This pelletizing extruder has the special screw design and different configuration, it is suitable for the recycling and pelletizing of raw materials such as PP, PE, PET, PS, ABS, PA, PVC, PC, POM, EVA, PMMA and the pelletizing of the raw materials with different colors.

2.The gearbox is high torque designed which attains the functions of low noise and stable operation. Surface of the screw and barrel has been special treated so that the screw and barrel are wearable, they can have a very plastification and mixing effect and the production capacity is high.

3. The extruder has the vacuum vented design which exhaust the vapor or gas during the production, so that the output can be more stable and the pellets are more dense.

Technical paramete

Model | Screw dia.(mm) | L/D | Screw speed (rpm) | power of main motor(kw) | Output(Kg/h) |

CAMX-45 | 45 | 25-34 | 20-120 | 5.5-11 | 18-40 |

CAMX-65 | 65 | 25-34 | 20-120 | 15-37 | 40-90 |

CAMX-90 | 90 | 25-34 | 20-95 | 37-75 | 100-300 |

CAMX-120 | 120 | 25-34 | 20-80 | 55-110 | 250-350 |

CAMX-150 | 150 | 25-34 | 20-80 | 110-160 | 300-600 |

CAMX-180 | 180 | 25-35 | 20-70 | 180-250 | 400-850 |

CAMX-200 | 200 | 30-35 | 20-60 | 220-280 | 600-1200 |

Product show

Our Services

Packaging & Shipping

FAQ:

1.What will be your end products?(cat/dog/fish feed?)

2.What capacity do you require?(How many tons/h)

3.Do you need a single machine or the whole line?

4.Do you need Computer automatic batching system?

1.The MOQ: one set/sets.

2.Payment terms is T/T

3.Delivery time is 1~3 month

4.The Prot:Shanghai in China.

5.Shipping Terms: FOB

- Q: Comparison of swing granulator, high-speed granulator, one-step granulator difference?

- Dry granulation can be added powder, additives, wet add powder, it will not work.

- Q: Waste plastics granulation EIA Report Sample

- The EIA form is also availableChasing the answerIn general, you are doing this project EIA tableSee what you'll do later

- Q: How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q: Plastic granulator feed roller does not turn is what reason

- You see whether the gear or chain is driven, if it is a positive gear or the chain is broken. There is also a two axis of its own teeth rotation, it may be broken bearings.

- Q: how about the market demand, which kinds of particles are usually divided? Which particle has a higher profit margin?

- Grinder, cleaning machine, extrusion machine, granulator, a few hundred thousand million yuan - set. I did it. Raw materials are LDPE, HDPE, PP and so on

- Q: how much the price, I hope to know a friend told me Oh, thank you ah!

- Dongguan Dongcheng Singapore Plastic Machinery Factory (general taxpayer) in Chinese manufacturing city - Guangdong City, Dongguan. We also Xinye expertise, since the inception of the factory, has always only plastic granulator, is committed to creating the first brand China professional plastic granulator concept, practice: integrity, professional, quality, efficiency of the concept of behavior. Emphasis on the unity of life and work, creating competitive advantages for customers. At present, we have a wide range of plastic products, three process standards, four series of products, 112 types of standardized specifications of products.Comprehensive models, leading technology is our goal, is our advantage. General plastic granulator, engineering plastics granulator in the model to achieve full coverage, special and special granulation machinery has also formed many series. Small series granulator granulator, ultra-low temperature series, ultra high temperature granulator machine series, blending smoke machine series, ultra high mixing rod machine series, special masterbatch rod machine series, magnetic powder extrusion machine and magnet powder smoke machine and many other models, on behalf of the industry leading technology level.

- Q: Dry granulator and wet granulation machine what is the difference

- General plastic and water will degrade the performance of plastic degradation will make significant decline, affect the product performance, so the new material is generally not wet, extrusion is to make the plastic particle drying.

- Q: May I ask who knows the plastic granulator manufacturers contact ~ figure

- China is the same, who knows who ah?. Otherwise, better contact

- Q: How can the granulator recycle the plastic bottle?

- Well, what is the sorting process of the plastic granulator?A typical process in which the discarded bottles will be sorted first on the basis of color and size sometimes. Once sorted, they need to be washed away; however, the washing machine, while in a piece, is not the most advantageous way. Therefore, to facilitate the washing process, the bottle is likely to be broken down into small pieces. Plastic granulator, plastic grinding machine can be used to do work, such as Jordan to reduce the manufacture of solutions. They let a shredder break down into smaller sizes and then send it to the cleaning station for a wide variety of plastic and PET containers. Check out some plastic crush videos. Once the bottle is torn and a suitable size is washed, they are not yet ready for processing into other goods.

- Q: How to solve the noise of plastic granulator

- Change the mute hob cutter or water ring pelletizer.

Send your message to us

CMAX Serious Single Screw Pelletizing Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches