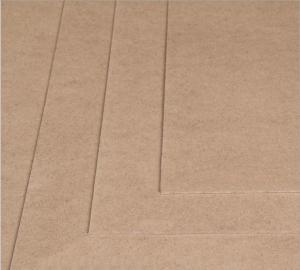

Plain MDF Board E2 Grade Good sanding Light Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Plain MDF Board:

General Information:

MDF board is a kind of wood based board made which is made from wood fiber and glue material under certain temperature and pressure conditions. The MDF board production line is from Diffenbacher.It can produce high-quality MDF board. MDF is a kind of good materials for furniture and decoraiton.

Features:

Eco-friendly

impact resistance

stable dimension.

Specification:

Material: Pine wood

Glue: E1 E2

Size of 1220x2440mm

Thickness: from 2 to 25mm

Moisture Content: 7-10% Storage Tray, low humidity

Certificate: ISO 9001,ISO14001,CEC

Minimum: 50m3

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- Q: The environmental performance of particleboard

- As the particleboard production process, the general use of formaldehyde-based adhesives, so its finished product will release more or less free formaldehyde

- Q: A simple introduction to particleboard

- sound and sound insulation is also very good. But it also has its inherent shortcomings, because the edge of rough, easy to moisture

- Q: Particleboard industry is currently looking ahead

- so the effective utilization of forest resources and papermaking pulp waste has been paid more and more attention

- Q: What is the production process of particleboard

- the plate thickness deviation and the degree of material transfer between the shavings

- Q: Particleboard by product classification

- According to the arrangement of shavings in the slab, there are two kinds of directional and random type

- Q: So for the particleboard formaldehyde release of the situation how to deal with it?

- turtle bamboo like green plants, not only can absorb formaldehyde can beautify the environment

- Q: Particleboard production requires proper moisture content

- According to the different density requirements of products, hot pressing pressure is generally 1.2 to 1.4 MPa.

- Q: According to the use of points: Class A particleboard; Class B particleboard

- According to the manufacturing method points: flat pressure particle board; squeeze particleboard.

- Q: How to improve the particleboard market space

- we must improve the scale of the project construction, the small particleboard factory to reorganize the small particleboard factory in order to improve the quality of the particleboard and reduce the cost and improve the research and development

Send your message to us

Plain MDF Board E2 Grade Good sanding Light Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords