1 2 in Particle Board Plain Honey Comb Particle Board for Door Core

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Product:

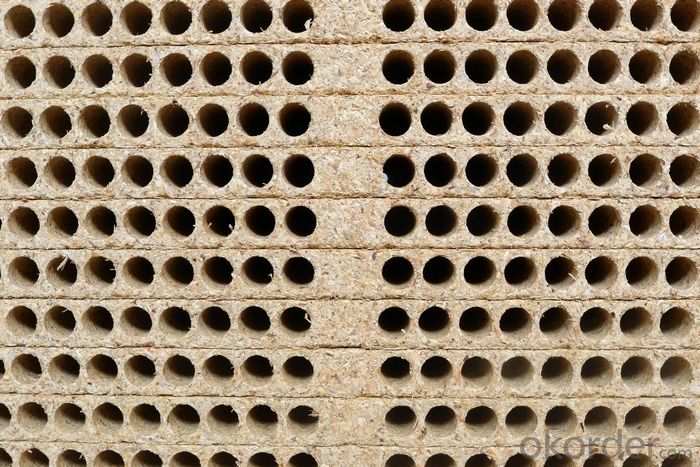

Plain Honey Comb Particle Board For Door Core

Advantages & application:

The door core with cross-drilled hole made by extrusion forming of large pressing machine has the following advantages compared with the door core with vertical hole.

1. All products are made by extrusion forming of large pressing machine. The holes are horizontal and the width of the pressing machine reaches 2040.

2. The holes are horizontal, no need of cutting during construction, improve efficiency and impact resistance.

3. It can be customized, accurate size, cut-free and loss-free.

4. Lock pinhole (There is a pinhole in the center of the door core, no need of cutting, a lock rod is placed, improve efficiency and impact resistance).

5.Eco-friendly, thermal insulation, sound insulation, light weight, impact resistance, stable dimension.

Specification:

Material: poplar, pine

Glue: E1

Width: 800-1400mm

Thickness: 24mm, 28mm, 30mm, 33mm, 34mm, 35mm, 38mm,

Length: 2090mm,2100mm

Bore Diameter: 18-27mm

Moisture Content: 7-10% Storage Tray, low humidity

Certificate: ISO 9001,CE

Photos:

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: Today's demand for wood-based panel products

- which gave the development of China's particleboard industry opportunities The Therefore, China's particleboard consumption is expected to increase year by year.

- Q: What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- Q: What are the raw materials for making the particleboard?

- such as linen (shavings) board, bagasse (shavings) plate. Adhesive multi-purpose urea-formaldehyde resin and phenolic resi

- Q: Particleboard industry is currently looking ahead

- Seeking resource-rich and inexpensive adhesives is an important factor in the development of particleboard production

- Q: Particleboard in the production process of environmental performance

- . First of all, the unused particle board piled in a small house, close the doors and windows

- Q: Particleboard production requires proper moisture content

- After the hot pressing of the particleboard should be a period of time to adjust the moisture content of its moisture balance,

- Q: How does the particleboard work?

- The process requirements are: ① appropriate moisture content. When the surface water content is 18 ~ 20%,

- Q: Particle shape is the decisive factor in the quality of the particleboard,

- Surface shavings are mainly made by cutting or processing of high-level residues (wood truncated, board edge, etc.) specially processed.

- Q: According to the use of points: Class A particleboard; Class B particleboard

- According to the manufacturing method points: flat pressure particle board; squeeze particleboard.

- Q: The product structure of the wood-based panel industry

- . Timber utilization is only 50% of the proportion of plywood is too large, accounting for 38% of the total output of wood-based panel, higher than the world average of 30%

Send your message to us

1 2 in Particle Board Plain Honey Comb Particle Board for Door Core

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords