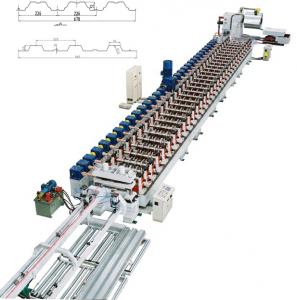

Pipe Rolling Bending Machine NC Single Chip 219 Seires

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Parameter of Pipe Rolling Bending Machine:

Items | Unit | Data |

Max. Capacity OD x WT (Mild Steel) | mm | φ50.8x2.5 |

Min. Bending Radius | mm | 30 |

Max. Bending Radius | mm | 350 |

Max. Bending Angle | ° | 190 |

Bending Speed (Max.) | °/s | 80 |

Bending accuracy | ° | ±0.15 |

Standard Length Over Mandrel | mm | 3200mm |

Main Control System | -- | NC |

Hydraulic Control System | -- | Solenoid Valve |

Motor Power | KW | 5.5kw |

Hydraulic Pressure Power | Mpa | 14 |

Size | mm | 4200x850x1030mm |

Weight | KG | 1500kg |

Control Way | --- | Industrial Computer |

Display Screen Size | cm | 13.8×9.8cm |

Oil pump | --- | Kaixi (Taiwan) |

Solenoid valve | --- | Qiyang(Taiwan) |

Auxiliary system | --- | Oil pressure system |

Bend method | --- | Double oil-cylinder chain driving |

Oil press system | --- | Taiwan Qiyang(three sections press) |

contactor | --- | Taian |

General Introduction of Pipe Rolling Bending Machine:

1.multi axles working simultaneously.

2.one key back up of programs for USB or disk storage.

3.security code for the protection the data setting and selected operation features.

4.manual step by step teach code for interference solution

5.diagnosis error immediately

6.To access to the history bending setting data to the facilitate study of malfunction with one set of tooling

Production of Pipe Rolling Bending Machine:

Other Information of Pipe Rolling Bending Machine:

1. Length over mandrel can made to order based on the customer request;

2.The Max. and Min. Bending radius can made to order based on the customer request

3.Tooling: Former Die, Pressure Die, Clamp Die, Ball Mandrel and Wiper Die (optional).

Packing & Shipping of Pipe Rolling Bending Machine:

1.Packaging Standard:

This commodity shall be packed in new wooden cases suitable for ocean transportation.

Control box and easy damage parts shall be wrapped up in seaworthy waterproof pape.

Packing must be seaworthy as well as strong enough to stand shock and rough handing.

2.Shipping:

the shipment within 30 working days upon confirmation of purchasing order or recepit of deposit.

- Q: What is the roll forming machine?

- The elliptical rolling machine is composed of a rolling device, a rolling pan, a transmission and a brake device, a base, a spindle assembly, a die seat elliptical movement device, a rolling head seat, an electric motor and an electrical control system

- Q: How is the molding machine installed?

- The position of the embedded parts of the forming machine should be accurate and firm, and the foundation should meet the design requirements and meet the strength of the permitted installation.

- Q: How to maintain the molding machine?

- 5 After the end of the work every day, the various parts of the machine should be in the initial state and thoroughly clean the various parts of the machinery to prevent concrete in the mechanical condensation, but not water washing machine;

Send your message to us

Pipe Rolling Bending Machine NC Single Chip 219 Seires

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords