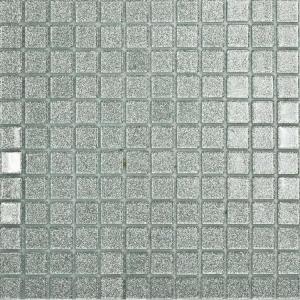

Pilate Stone 600 Polished Porcelain Tile From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1324 carton

- Supply Capability:

- 1324000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

Polished Porcelain Tile, Double Loading

Only Grade AAA available

Strict control on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Professional sales team for product, document and schedule of importing and exporting.

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 85 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

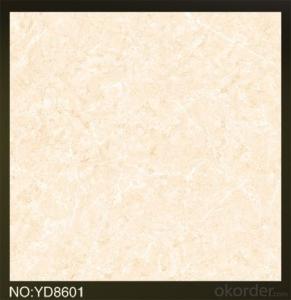

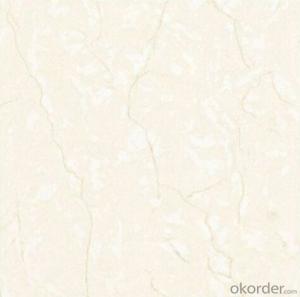

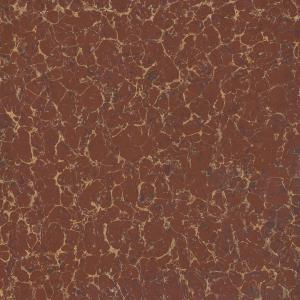

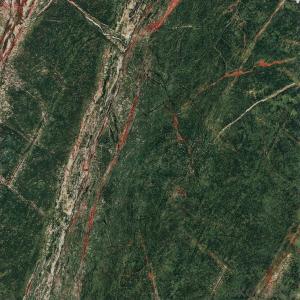

Pictures

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: i‘m planning to change the tiles in my tub area. whats the right way of doing this? should i change the drywall to cement backerboard? and how do i fix the joint between the new cement backerboard and the existing wall and ceiling which is textured? pls help!

- in case you're applying great 1ft sq. tiles, and your chum did a foul interest on the the mosaic tiles i does not propose doing it. the load of the tiles could loosen the the smaller tiles inflicting the bigger tiles to fall. this may be risky in a tub or bath section. The tiles could shatter leaving sharp little shards of tile everywhere, alongside with interior the flesh of everyone interior sight. i replaced into going to place sixteen x sixteen tiles in my bathe section, and a contractor suggested I greater constructive be useful the wall above the bathe is shelter because of the fact if one got here loose and hit me interior the top it does not be sturdy. I went with little a million x a million tiles on the ceiling with greater tiles on the wall. despite you submit is in basic terms going to be as shelter as what's in the back of it. in basic terms my opinion, yet for safeties sake, i could get rid of the previous tile and start up over. bear in mind, there is by no skill adequate time or funds to do it suitable the 1st time, yet there is often adequate time and funds to do it over!!!

- Q: The ceramic tile in my shower is looking really shabby and I‘d like to re-do it in subway tiles on the walls and mini hexagonal tiles on the floor. Has anyone ever re-tiled an old shower? What should I keep in mind? It is a single story house that is about 30 years old and I beleive it is all the original stuff.

- Depending on your budget I would consider having them professionally refinished. They can do a great job and even change the color. But, if you want to tear them out you will have to install new backerboard(like concreate, called hardiboard). It can be very tedious and time consuming, you'll also need to rent a wet saw to cut the tiles. It will also be very messy and your bathroom will be out of comission for a few sayd if you are doing the work yourself, so I hope you have 2.

- Q: OK here is my problem. I want to switch my bath tub to an all-tile shower and wonder how to do it. So far the tile were set onto a cement board that was itself put on top of the drywall. I am wondering if this is a common thing. From all my research, it looks like tile should be on the cement board, but there is no use for extra drywall behind it. It actually makes things tougher because you need some sort of corner tile instead of normal bullnose since the cement board and the rest of the wall are not at the same level.My second question is: is there an order to do all this i.e. should I make the shower pan (sort of rubber sheet filled with cement), before or after I install the cement board on the wall. Is there a specific angle used for the drain?Thanks in advance for all your tips.

- Tile looks great but is a real problem to keep mildew free. We lived in Houston for 20 years and had a tiled shower, it was a constant battle. We now have a cultured marble shower. Mildew is not a problem. I would not have any other type of shower. It is always clean and just a little spray with one of those new spray products and there is no soap scum to deal with either. It is less likely to have leak problems as well. If you are going to live in the house for a while, go with the cultured marble.

- Q: All together, which one is more expensive to install and buying the tile or wood? Thanks!!! And if you can, leave site names.

- carpet, baileys

- Q: I have a 15x15 tile that is on the floor in front of a gas fireplace (never been used) that has a hairline crack in it. The tile is one of 4 on the floor and matches 8 others that ring the face of the gas fireplace, the bathrooms and the kitchen. I cannot find the same tile to replace it. There is no elevation difference across the crack.Is there a method to fill the hairline crack so it doesn‘t stand out like a sore thumb?

- Try adding some dye to grout to match the color. You will still know the crack is there but nobody else will! You can also use silicone but its harder to work with and doesnt last as long. You may want to experiment with the color by mixing a couple different colors to see which one is the best. Get the dye from a masonry or tile supply house. It is meant for grout. Have fun, Dan

- Q: Dongpeng tiles I know more famous, but Dongpeng sanitary ware is their home Well? Dongpeng still have to sell sanitary ware?

- There is ah! Are ceramic products! Foreign Wrigley, Kohler (USA), Lejia (Spain), TOTO (Japanese devils, not recommended to buy).

- Q: for diferent size tiles are there standard grout joint sizes

- This Site Might Help You. RE: what size grout joints for ceramic tile? for diferent size tiles are there standard grout joint sizes

- Q: What are the benefits of installing tile in kitchen and bathroom or would linoleum be better? Also, how hard is it to install tile floors. I‘ve had friends who‘ve had no experience and they did it and did a good job. I am just a bit skeptical of doing it myself but just wondered if there are videos out there that shows you how to do it.

- There are several videos on installing ceramic tile. If you go to any home center (Home Depot, Lowe's or Menard's) you can get on and even how to books. You can also check out the library and rent a video and most times the how-to are free. As far as installing tile, I have worked in home improvement for 13+ years and it really is easy. It all starts with the sub floor preparation. Usually home owners have to install 1/4 tile backer over a bed of mortar using a 1/4 notched trowel. The advantage of putting tile in your kitchen/bathroom is the durability. The tile is not going to tear, stain, discolor or fade. Plus it should add value to your home having in your home. I hope this helps you out.

- Q: This is a first time tiling job. Does anyone have any tips to how to properly lay tile?

- I have been a tile installer for over ten years now. Basic tile installations, such as floors and backsplashes are perfectly fine for any homeowner. There is not much that can go wrong ( mainly Aesthetics) When is entails water related installations ( Wet areas). This is when a homeowner can get in over their heads. Water will find its way out if a stall is not properly prepped and waterproofed. I honestly would recommend hiring a professional. Just my opinion.

- Q: Kitchen is open to living area. Kitchen has tile already and living room has carpet. We want replace carpet wit hardwood if it look right, or should we just tile it all. Entry way from frony door is tile then living room begins with carpet then kitchen begins with tile.

- do the hardwood with the tile

Send your message to us

Pilate Stone 600 Polished Porcelain Tile From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1324 carton

- Supply Capability:

- 1324000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches