Phenolic Foam/Polyurethane Sandwich Panel Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Phenolic Foam/Polyurethane Sandwich Panel Production Line

Introduction of the Equipment

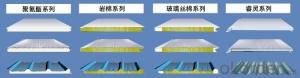

Phenolic Foam/Polyurethane Sandwich Panel Production Line is a professional machine for manufacturing Sandwich Panels of which the core material is phenolic foam or polyurethane and of which both layers is embossed aluminium foil or colored steel. The thickness of sandwich panel is 20-200mm, the width 1200mm and the length according to customers’ request. The sandwich panels are used as the air ducts in Central air conditioning. The machine can used to make other insulation panel as long as the surface material is changed. The working principle of the machine is as below: mix the raw materials with a certain ration in a container and then pour the mixture on the interlayer of the sandwich panel. Then the raw materials has the chemistry reaction of foaming and solidifying. In the end the automatic tracking cutting machine cuts the panels into a certain length.

The Components and Its Function

The components include: the aluminium foil embossing machine, the raw material distributor, the aluminium foil/colored steel pre-heating installation, the material-baffling mechanism, the automatic tracking cutting machine, the roller supporters and brackets. All the components can be individually adjusted.

The Aluminium Foil Embossing Machine

The embossing machine include three parts: the charging unit, the embossing unit and the windin unit. It is used to emboss figures and logos under certain surface tension on the aluminium foil (Width: 1200mm, thickness: 0.08-0.12mm).

The Raw Material Distributor / The Raw Material Charging Unit

This device is installed at the forefront of the production line and the laminator. It can adjust the location and control the surface tension of the aluminum foil and the colored steel before entering the laminator.

The Aluminium Foil/Colored Steel Pre-heating Installation

Before entering the injection machine, the temperature of the aluminum foil or the colored steel must meet the requirement of the foaming technology of the PF or PU. And thermodynamic cycle device on the production line can control the temperature of the aluminum foil or colored steel.

The Material-baffling Mechanism

The material-baffling mechanism is used to stick Kraft paper to both sides of the lower aluminum foil before entering the injection machine. So there is a enclosed area between the upper aluminum foil and the lower one. With the Kratf paper, there will be no leakage of the raw materials when the machine is working.

The Reaction Injection Machine

The reaction injection machine is used to calculate the computation and mix of raw materials pro rata. In order to make the temperature of the raw materials meet the requirement of the foaming technology, the machine is equipped with heating, refrigerating and temperature control devices. In addition, People can control the pressure, the computation of the raw matrials by this machine. And the process of injection, cleaning and sweeping are automatically controlled. The equipment is equipped with three tanks, two for resin materials, one for curing agent material.

The Back-and-forth Injection Machine

This machine is used to apply the mixture on the lower aluminum foil or the colored steel. The injection head is drived by fluid drive, and its speed, moving frequency, transverse moving distance is adjustable.

The laminating conveyor is used for the laminating and the shaping of the sandwich panel. This machine adopts the driving structure of drag chain. The chain is made of fine aluminum alloy and is 18m long. The moving speed is 3-8m/min and is controlled by frequency conversion. If the customers want to improve the moving speed, they can customize a longer conveyor. The thickness is controlled by the space between the upper link plate and the lower one. The startup of the link plate is control by fluid drive. The 12 tilt cylinder is adjustable so that the link plates can stops at any position.

The Heated Air Circulation Device

To meet the expected requirement of foaming technology, the production line is equipped with a heated air circulation device. Its used to heat the link plates to 70℃. Its made up of one hot blast stove, one diesel-oil-drived stove and two temperature sensors. The temperatue sensors are placed at the inlet port and inside the conveyor so the operator can monitor the temperature fluctuation.

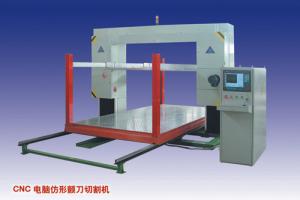

The Automatic Tracking Cutting Machine

The panels are cutted into different lengths by this machine.

MAIN TECHNICAL PARAMETER OF THE PRODUCTION LINE

Specification of Sandwich Panel | Width*Thickness (mm) | 1200×(20~200) |

The Production Speed | m/min | arbitrary |

The Embossing Speed | m/min | ≤20 |

The Mixing Speed | round/min | 4500 |

The Moving of Injection Head | times/min | ≤80 |

The Max temperature of the heated air circulation device | ℃ | 70 |

The Laminating Length of the Conveyor | M | 18.82 |

The Max start-up Speed of the Conveyor | mm | 300 |

Total Power | KVA | 85~125 |

The Specification of the Production Line | mm | 40950×5620×3700 |

The Specification of the Embossing Machine | mm | |

Weight | T | ≈34 |

Note: The above information is for our standard production line and we can make it according to customers request. We will send our techician to our customers to install and debug the machines.

- Q: The old roof to re-laying insulation materials and sand cover paving waterproof material about how much cost

- Through the field spraying process in the roof to form a continuous, seamless shell, effectively eliminating the hot and cold bridge effect, to achieve insulation and waterproof integration

- Q: What kind of material is used in the explosion-proof clothes in the bomb disposal unit?

- Anti-riot clothing, also known as anti-riot armor clothing

- Q: 81-1 automatic rifle and 95-type automatic rifle distinction between where? What are the common points? The soldiers answered the best.

- 8 mm class with the gun family, certainly better than the 7

- Q: Seek a kindergarten class open class lesson plans! The The Online and so on! The The Solve!

- They love to watch the vehicles, especially the middle class children have been able to identify some of the common car, and like a variety of car toys demolition and then reload

- Q: Conference hall sound insulation design, material purchase? Need to pay attention to what?

- Sound-absorbing material can choose wood perforated sound-absorbing panels (with keel fixed to the wall, behind the cavity filled with sound-absorbing cotton), can also Select the polyester fiber decorative sound-absorbing panels (directly attached to the wall); in particular, pay attention to the sound-absorbing material is environmentally friendly and flame retardant, which is a matter of life

- Q: How is the multi-functional waterproof coating? How much is a bucket?

- 【Features】 the coating of high strength, elongation, the grass-roots shrinkage and deformation of the strong adaptability

- Q: How can I choose the most suitable for your own power tools?

- Coupled with a transfer rod and ordinary drill chuck, it can complete the hand drill function, to achieve the purpose of a multi-purpose machine

- Q: Is there any material on the market that is dedicated to wall waterproofing?

- You recommend you choose Dongfang Yuhong waterproof products and standardized construction team, the East Rainbow is the best quality waterproof listed enterprises RPUF-371 sprayed foam polyurethane waterproof insulation integrated system "rain rainbow" spray foam polyurethane waterproof insulation integration system Is composed of rigid foam polyurethane foam waterproof insulation integrated material and protective surface layer composition

- Q: I want to buy Yuba everyone to recommend a, what function how much money

- I want to buy Yuba everyone to recommend a, what function how much money

- Q: Why construction gypsum is a good interior material and is suitable for outdoor use

- Plastering the walls and ceiling can also be directly painted paint and paste wallpaper Building gypsum water into gypsum slurry, into part of the lime, can be used as indoor paint paint After the painted wall of the official words delicate, white and beautiful General construction gypsum is not used for outdoor, and gypsum does not apply to load-bearing components, the most may be the production and application of gypsum board, China's current production of gypsum board is mainly paper gypsum board, gypsum hollow slab, gypsum decorative plate and Fiber gypsum board, and most of the interior wall and ceiling for the interior Building gypsum for outdoor use is rare, and there are also possible decorative garnishes made of cast gypsum, such as gypsum statues, decorative panels and various other decorations Personal humble opinion what

Send your message to us

Phenolic Foam/Polyurethane Sandwich Panel Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords