Heat Sealing Property Metalized CPP Film From China

- Loading Port:

- Ningbo Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Metric Tons m.t.

- Supply Capability:

- 700 Metric Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification Of Heat Sealing Property Metalized CPP Film From China

Thickness of film | Thickness of aluminum layer | Width | Diameter | Core size | |

18,20,25,30μm | 350-380Å | ≤2320mm | ≤800mm | 76mm(3″)152mm(6″) | |

Typical product performance: | |||||

Item | Unit | Standard value | Test method | ||

Thickness of film | μm | 25 | ASTM D-374 | ||

Tensile Strength | MD | Mpa | 54 | ASTM D-882 | |

TD | 33 | ||||

Elongation | MD | % | 565 | ASTM D-882 | |

TD | 612 | ||||

Heat seal strength | N/15mm | 11.2 | ASTM D-882 | ||

Wetting Tension | mN/m | 38 | ASTM D-2578 | ||

Friction Coefficient | —— | 0.62 | ASTM D-1894 | ||

Haze | % | 2.7 | ASTM D-1003 | ||

Glossiness | % | —— | ASTM D-2457 | ||

Thickness of Aluminum Layer | Å | 380 | |||

(Square resistance)Ω/□ | 2.7 | GB/T 15717 | |||

(Optical density )O.D | 1.9 | X·Rite361 | |||

(Light transmittance)VLT | 1 | ASTM D 1746 | |||

Equality Tolerance of Metallizing Layer | % | ±10 | GB/T 15717 | ||

Combining Fastness Tolerance of Metallizing Layer | % | Aluminum fall off ﹤2 | 3Madhesive tape | ||

Moisture vapor transmission rate | g/m2·24hr | 0.5 | ASTM E96 | ||

Oxygen transmission rat (23℃,0%RH) | cm3/m2·1atm·24hr | 45 | ASTM D1434 | ||

Features Of Heat Sealing Property Metalized CPP Film From China

1 Good adhesion, well proportioned,

2 Heat sealing property

3.The film with heat sealing property, which can be laminated with BOPP,PET using for convention, it is extensively using for packaging industry.

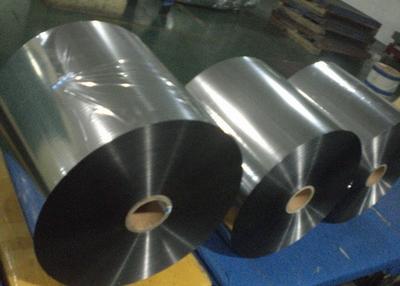

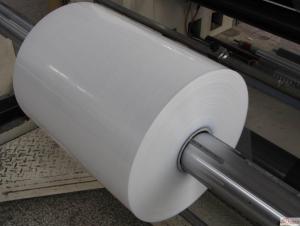

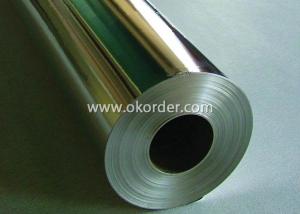

Pictures Of Heat Sealing Property Metalized CPP Film From China

- Q: What is the impact of TPO waterproofing membrane welding performance?

- 2. The surface cleanliness of the web; 3. Does the welding temperature match the welding speed; 4. Welding method, test welding, manual three-step welding.

- Q: Waterproof electrode, waterproof welding

- Sewage equipment repair with time urgency, uncertainty, characteristics of labor intensity and so on. Requiring repair personnel in the shortest possible time to complete the repair and safe and efficient tasks, to ensure smooth flow. But in the process of repair the situation is changing, and sometimes seemingly simple process often have unexpected circumstances. Such as steel pipe repair, in general, as long as the welding can be, but sometimes for some reason the water inside the pipeline can not drain, which to welding and cutting to bring great difficulties

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- The surfacing isolation layer is mainly used to separate the main surfacing layer from the base metal, especially when the surfacing layer is welded directly to the base material. It is usually used with the third component, but with the surfacing layer and Base metal can be a good fusion of metal welding consumables, in the surfacing surface of the first welding a layer, and then on this basis and then need to re-welding the metal.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | Above RMB100 Million |

| Main Markets | China; Eastern Europe; East Asia; Japan; Western Europe; Africa; Southeast Asia; North America; South America; Hong Kong and Taiwan. |

| Company Certifications | ISO9000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo port; Shanghai port. |

| Export Percentage | >50% |

| No.of Employees in Trade Department | 8-10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Heat Sealing Property Metalized CPP Film From China

- Loading Port:

- Ningbo Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Metric Tons m.t.

- Supply Capability:

- 700 Metric Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords