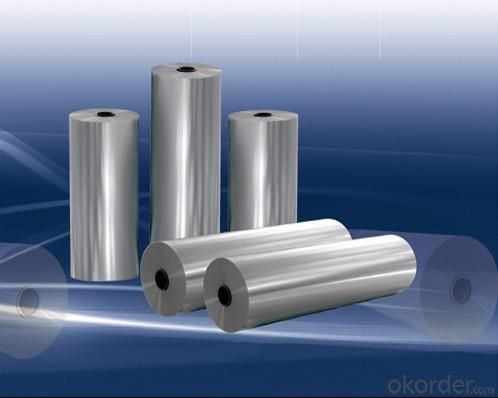

PET Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 TONS m.t.

- Supply Capability:

- 20000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PET Metalized Film Lamination

Description:

1. Thickness: 38 micron

2. Width: under 1250mm

3. Paper core: 3" (76mm) or 6" (152mm)

4. Feature:

1) Smooth and clear surface

2) Good printing quality and fireproof properties

3) Heat resistant, water proof, stable at high temperature or in boiled water

4) Environmentally friendly, no smell and non-toxic

PET Metalized Film

Using polyethylene as carrier, it can be used for very wide applications because of its excellent mechanical and chemical properties. it is an ideal material to make flexible packages as the metalized layer creates a great barrier to oxygen, light, and moisture and as a result prolongs product shelf life substantially.

On the other hand, it can be laminated to cardboard to make fabulous packages. It can also be used to make stationery and toys such as adhesive tapes, stickers, or used as varnishing film.

- Q: What are the factors affecting the permeability of plastic film?

- Film properties. The permeability of polymer film is related to its structure. The permeability of polar film is larger than that of non-polar film, and the amorphous film is larger than crystalline film. In addition, the permeability coefficients of some polymer films are similar to those of saturated vapor pressure. The permeability coefficient of polyethylene and nylon films is several times higher than that of moisture permeability. This is mainly due to the formation of pores between crystals or grains, which facilitates the flow of liquid water.

- Q: Should the surface of the plastic film be removed when the activated carbon is used?

- Need demolition. Make a small cloth bag and pack it up. Because activated carbon must be in contact with indoor or closet air, it can absorb toxic or harmful gases or air moisture, plastic film will prevent it from contact with the air.

- Q: Can the concrete be covered with plastic film in summer?

- Summer maintenance to cover the film..And the film should be sprinkler maintenance,First, because the temperature of concrete and the internal temperature can not be too different,Otherwise, thermal stress. Internal expansion. External contraction. Produces cracksSecond. The hydration heat of the cement needs only twenty percent of the actual water, and the rest will evaporateAll water evaporates to form a contractionWe are here it is. For example, a pier pier. All set on film.Then put a bucket on top and fill it with water,Slowly drop, let the water covered pier surface. The surface temperature is reduced.

- Q: The plastic film on the mattress doesn't tear off. Is it good for the body to sleep?

- The film is to prevent the cushion for a long time, wet, and then there is this layer of film is not easy to dirty the mattress, and the normal shop will be covered with a thin layer of mattress, laying in the sheets on it. No harm to the body!

- Q: Genuine Clinie mask packaging has no plastic film

- If that is the box, is not only a plastic, paper shell. If it's one of those dozens of pieces sold in one bag, then it's a plastic bag. I just went to Korea on New Year's day. I remember it very well.

- Q: Why should antistatic treatment be applied to plastic film printing? What are the treatment methods?

- Due to electrostatic adhesion, the air can not enter between the film and the film, hindering the continuous drying of the ink layer. In the environment of high temperature and high humidity, easy to form a layer of ink adhesion. Light makes the ink printing part of denim, while the film is not easy to open, thus becoming the image plots debonding, scrap, resulting in economic losses.

- Q: What's the packing material for yogurt?

- Yogurt packaging mostly for blister and blow molding, material PE, PP based, plastic film mostly BOPP film, carton packaging higher cost, carton packaging basically three layer printing layer, carton and inside a layer of film

- Q: Do you have adhesive for plastic film?

- The main ingredients of polyethylene for delta ethyl cyanoacrylate glue. In the air of trace water under the catalysis of additional polymerization, rapid curing and adherend glue.PE and PE (polyethylene) materials, and PE (polyethylene) and all plastic, metal, wood, ceramics, stone, rubber and other materials of the fast, perfect bonding. The adhesive strength can reach the super effect of tearing material.

- Q: What is a water-soluble plastic packing film?

- Water soluble plastic packaging film as a new green packaging materials. The main raw material is low alcoholysis of polyvinyl alcohol film, water solubility and degradability by polyvinyl alcohol, adding various additives, such as surfactants, plasticizers, anti adhesive agent. Water soluble film products belong to green packaging materials and in Europe, Japan and other countries have been recognized by the national environmental protection department. At present, the main domestic and foreign biological oxygen demand (BOD) and chemical oxygen demand (COD) as an environmental indicator. The Japanese authorities determination of PVA biological oxygen demand (BOD) is much smaller than the starch, the United States Air Products to PVA biological products Airvol, after 5 days degradation can be measured the amount of BOD is lower than the initial volume of BOD 1%. through the biological experiment proved that polyvinyl alcohol are non-toxic, does not prevent the growth of microorganisms, has no influence on wastewater treatment and environmental health The microbial decomposition tests also showed that the PVA was almost completely decomposed, resulting in a very low COD

- Q: Why is plastic film made of hand made paste of composite material?

- FRP hand lay up after the release, must be to achieve, but the smooth emergence is very important, because of the characteristics of thin flat and smooth, easy to make glass steel and mould to form two layers, not due to the small defects of the mold surface due to adhesion, so that the surface is beautiful and easy demoulding.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East;Eastern Asia; Western Europe; Central America; |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wenzhou Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High;Average |

Send your message to us

PET Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 TONS m.t.

- Supply Capability:

- 20000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches