PET Bottle Shrink Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Equipment profile:

Concise and beautiful appearance, novel structure, unique, easy maintenance. Electronic sensing film conveying, the stability of membrane, the quick change film.

Using constant temperature type sealing and cutting knife, the sealing strength 3 times for cold thermal cutting knife, uniform smooth seal, service life is 80 times of the cold sealing heat sealing knife

Frequency control of motor speed transport agencies, transmission synchronization precision, reliable transmission

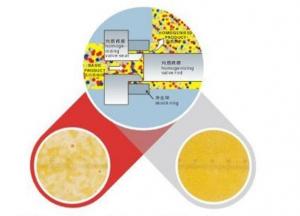

Shrinkage chamber adopts circulation wind technology, reasonable structure, heat insulation, high temperature control precision, shrinkable packaging effect is better.

During the product forward conveying process, it can automatically group the product into package,so as to save time enhance packing efficiency.

The ideal model of middle & high-speed heat-shrinking packager is the first choice in the domestic market. Simple operation, convenient maintenance.

Technical parameters:

Name | BS Series Full Auto Hot Shrinking Package Machine | |

Application | Suitable for the high-speed packing requirements of drinks (pure water, beverage, fruit juice, and milk product). The ideal model of middle & high-speed heat-shrinking packager is the first choice in the domestic market | |

Combination property | Equipment Effectiveness | Can automatically control the shrinkage and the sealing and cutting temperature,can be adjusted as required |

Adopts tap design, also suitable for different bottle diameter and combination of packing | ||

Adopts constant temperature type sealing and cutting knives anointing Dupont Teflon,To ensure the quality of incision | ||

Equipped with Siemens contactor and hayley's frequency converter | ||

Equipped with Krones shrinkage chamber wind circulation structure | ||

Equipped with photoelectric sensor of Autonics | ||

Operation and maintenance | Using OMRON PLC touch screen and programmable, operation more convenient | |

The integration of design, support high efficiency, continuous operation | ||

The main parts detail:

Parts | Using technology | Brand |

Constant temperature type sealing and cutting knives | Teflon anti-sticking coating | USA DUPONT |

PLC controller(Automatic control of the core components) | France | Schneider |

variable-frequence governor | France | Schneider |

All air cylinder/air valve(Core components mechanical action) | Taiwan | UNIQUC |

Close to the electronic switch | Korea | AUTONICS |

Touch screen | France | Schneider |

Contactor | Germany | SIEMENS |

Regulator device | Taiwan | MINDMAN |

Motor protector | Germany | SIEMENS |

Shrinking machine mesh conveyor belt | America | DUPONT Teflon fibre |

Intermediate relay | Japan | OMRON |

- Q: Liquid Filling Machine Optional Accessories

- A. Needle filling head: for small caliber bottles and hose packaging products filling.

- Q: What is the purified water preparation system?

- US Pharmacopoeia from the 19 version began to carry this method, for the preparation of water for injection one of the legal methods.

- Q: What is a tubular filter?

- 2. Acid, alkali, salt and a variety of organic solvents, non-toxic, tasteless, no foreign body off

- Q: Cleaning and maintenance of what the way

- Cleaning knife knife method: first with the cotton ball will be the next mold of the two drain holes plug, the water into the mold groove, fill up so far, and then pushed into the lower mold slide in place, the pressure on the press

- Q: Self-cleaning water filter is what

- The third source is the particles in the air that accumulate on the open surface.

- Q: Public water treatment system

- Sea water brackish water desalination, schools, communities, hotels, real estate property quality water supply network system.

- Q: What is the paste filling machine?

- And when the machine is in the "manual" state, the operator step on the pedal, to achieve filling, if you have been tucked, then also become automatic continuous filling state.

- Q: How to choose the cooling tower water treatment sterilization equipment

- Cooling tower which often have a lot of sticky mud, the traditional method needs to be washed after the addition of special water treatment sterilization algae pharmacy, it is troublesome.

- Q: What are the advanced sterilization techniques and equipment

- In the 1950s, European dairy research workers began to use the original method of processing canned food (120 ℃, 15 minutes, see Table 1), manufacturing "keep sterilization" milk caused by serious damage to milk nutrition

- Q: What are the main water treatment equipment used in the industry?

- , Urban construction (precipitation water treatment), food (purified water), laboratory (analytical water) and so on.

Send your message to us

PET Bottle Shrink Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords