Pellet mill pellet-fodder expander wood pellet mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wood pellet machine, is also named wood pellet making machine, sawdust pellet machine, power pellet machine, straw pellet machine, biomass pellet machine, rice husk pellet machine,organic fertilizer pellet machine, feed pellet machine and straw coal making machine.

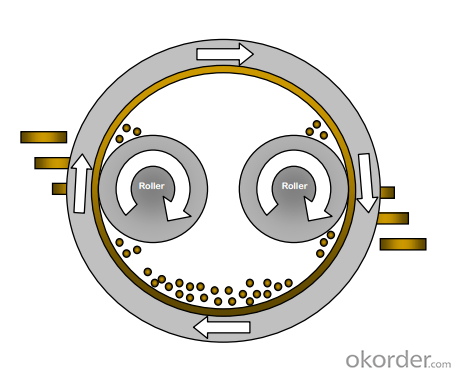

The new wood pellet machines solve the problems effectively of biological crude fiber granulating hardly and less effective. The main part works with high standard overloading reducer, which can ensure the power transmission efficient, stable, low noisy and longer lifespan by choosing high quality bearings. Ring die adopts the quick-release anchorear type, feeding conveyor adopts inverter to adjust the speed to feed more evenly. The new wood pellet machine adopts international advanced manufacturing technology, “roller wraps” is made of high alloy wearable material, this models have characteristics of unique design, reasonable structure, high efficiency and long lifespan.

Features:

1. High efficient, centrifugal, high pressure power, suitable for quenchless materials

2. Low wear rate, long lifespan for ring die and roller wraps

3. Rollers are with automatic lubrication system, can work continuously

4. The ring die adopts vertical type, can feeding upright with high efficiency, and is good for dissipating heat.

5. Long working life for ring dies: being made of alloy steel with special processing technic, having hard and wearable surface and tough inner part, having high impact toughness at low temperature.

6. Cost-effective: on the basis of the similar equipment, improving the technological content and function of machines. Full consideration on the price for the affordability of wide users.

Suitable range and application:

The product is applied to materials with low adhesiveness and quenchless. For example, rice husk, sunflower husk, peanut shell, fruit shell; branches,tree trunk,tree bark, kinds of wooden waste; kinds of crops straw; rubber,coal ash and other chemical raw materials. Applied in animal feed factories, wood processing plants,synfuel plants, fertilizer factories, chemical factories, etc, they are the most ideal compression molding equipment with small investment, quick effect,risk-free.

- Q: What are the public companies that produce feed processing machinery enterprises

- Mainly engaged in feed and veterinary biological products primarily in veterinary medicine production and sales, is the largest in xinjiang region of feed production enterprises, and through the national ministry of agriculture GMP certification of national one of 57 veterinary biological products manufacturing enterprises. The clear growth in 2009 came from the expansion of feed capacity and recovery. The expansion of corporate feed capacity in 2009 will drive the business to more than 100 per cent of earnings: 1) the new unit's full-year profit for 2009. In 2008, the company's feed production was about 290,000 tons, while the newly acquired Hong Kong and zhengzhou products unit sold about 350, 000 tons, net profit of about 2,300 million to 24 million yuan. The company completed 100 percent equity acquisition in mid-november 2008. According to the accounting rules, the company only consolidated its net profit in December of the year, while 2009 will consolidate its full-year net profit and the company will gain more than 20 million yuan per year. The company's annual production of 60,000 tons of feed is expected to start production in August 2009 and is expected to increase net profit by about 1 million yuan in 2009. 3) as the price of feed raw materials such as soybean meal is falling, the feed industry is recovering, and the profit margin of the company's feed business is expected to improve.

- Q: What equipment does the production of feed premix need?

- Big mixing machine, small premixed machine a, mill a (look), and so on and some necessary machinery and equipment, we also do this, you give some points!

- Q: I want to open a private chat factory in a county-level city around the provincial capital.

- I have been in the feed factory for many years, the benefit is best is the pig, rabbit feed is the last chicken feed, do you do the whole price or the concentrated material? Knowing what you want to do with your plan is how much money you want to get out of the device. Be sure to be built in the traffic is the best place that has the railroad, your product cost ability is low otherwise have no competition ability, I don't love typing you can call to consult me

- Q: What kind of equipment is needed for the processing of 100 fragrant pulp for cattle feed

- Feed, or break, and then feed with other green fodder.Depending on the extent of the process, you will need a shredder and dryer..

- Q: The price of complete equipment for large animal feed machinery

- According to the latest technology requirements of the country (feed enterprise production process and equipment acceptance standard rule). Assist the feed production enterprise to meet the acceptance criteria. Feed processing equipment is used for the processing of powder or granular feed, such as livestock and poultry, aquatic products, cattle and sheep.

- Q: Method of crushing of feed mill

- chop saws: use two toothed and rotational speed of different roller surface will chop material, its advantage is easy to dig thickness degrees, less power, storage, suitable for processing grain materials, bread slag, etc.

- Q: Feed plants open what feed equipment

- Production from cows need delivery before and after birth, calf back before and after the island into adulthood cowshed, youth shelter, mother into the barn and milking parlour build, such as, as far as possible do streamline, and mutual interference, convenient production, deal with their relations, meet the needs of the production of the dairy life, and at the same time considering the barn to sports venues, diagnosis and treatment, health care facilities to cows to create a quiet and comfortable living environment. Even: beginning from the cow lie to gather the food, drinking water, the movement to the environment temperature, moderate, air quality, lighting control omni-directional design, provide services to the health of the dairy life.

- Q: What equipment does a complete small feed processing plant need?

- Chicken feed for grain more commonly, this requires a particle machine, and then form a complete set of equipment, mixer, crusher, sizing screen waiting for you to consult Jim grams of feed processing equipment factory, can according to your need for your details you need

- Q: What is the price of a machine that processes straw feed? Specifications? The more detailed, the better

- Tested normal maize straw nutrition level northeast l. chinensis and its comparison with conventional straw, feeding cattle weight increased by 15%, feeding cow milk production increased by 16.4%, butterfat rate increased by 0.2%, at the same time can save 30% of roughage, comprehensive costs fell by 20% for the cow feeding water conservancy science research institute of Inner Mongolia results show that with the silage maize straw contrast, feeding cattle daily gain by 24-39%, efficiency is more apparent. Economic benefits. The main ingredients of coarse feed as a coarse feed are especially affordable, cheaper and cheaper.

- Q: How much is the machine for the corn stalk processing feed

- Production process: The straw granulator is the main raw material of crop straw or wood chip, and it is compressed into a cylindrical particle by a straw granule machine. Depending on the quality of the raw material, the particles that are pressed can be used as biomass fuel and as feed for livestock and poultry.

Send your message to us

Pellet mill pellet-fodder expander wood pellet mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches