wood pellet mill wood pellet making machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wood pellet machine, is also named wood pellet making machine, sawdust pellet machine, power pellet machine, straw pellet machine, biomass pellet machine, rice husk pellet machine,organic fertilizer pellet machine, feed pellet machine and straw coal making machine.

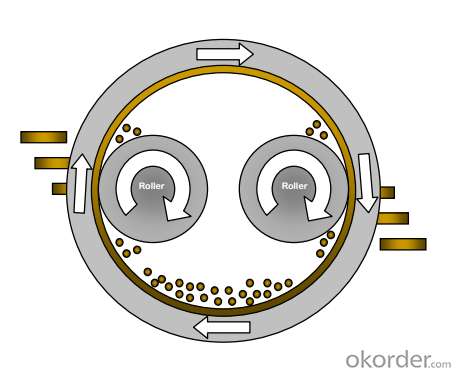

The new wood pellet machines solve the problems effectively of biological crude fiber granulating hardly and less effective. The main part works with high standard overloading reducer, which can ensure the power transmission efficient, stable, low noisy and longer lifespan by choosing high quality bearings. Ring die adopts the quick-release anchorear type, feeding conveyor adopts inverter to adjust the speed to feed more evenly. The new wood pellet machine adopts international advanced manufacturing technology, “roller wraps” is made of high alloy wearable material, this models have characteristics of unique design, reasonable structure, high efficiency and long lifespan.

Features:

1. High efficient, centrifugal, high pressure power, suitable for quenchless materials

2. Low wear rate, long lifespan for ring die and roller wraps

3. Rollers are with automatic lubrication system, can work continuously

4. The ring die adopts vertical type, can feeding upright with high efficiency, and is good for dissipating heat.

5. Long working life for ring dies: being made of alloy steel with special processing technic, having hard and wearable surface and tough inner part, having high impact toughness at low temperature.

6. Cost-effective: on the basis of the similar equipment, improving the technological content and function of machines. Full consideration on the price for the affordability of wide users.

Suitable range and application:

The product is applied to materials with low adhesiveness and quenchless. For example, rice husk, sunflower husk, peanut shell, fruit shell; branches,tree trunk,tree bark, kinds of wooden waste; kinds of crops straw; rubber,coal ash and other chemical raw materials. Applied in animal feed factories, wood processing plants,synfuel plants, fertilizer factories, chemical factories, etc, they are the most ideal compression molding equipment with small investment, quick effect,risk-free.

- Q: What is the mechanism of feed machinery

- Feed expander machine can be used for the expansion of raw materials such as corn, soybean meal, bean meal, rapeseed meal and cottonseed meal. Expander, feed expander,

- Q: What are the public companies that produce feed processing machinery enterprises

- Company established the basic layout, the three major industries in public utilities, which is mainly on the real estate industry into a new profit growth point, on the basis of modern agriculture, shaping kanter transportation, water supply, real estate, property management, feed, breeding six big brand in the industry development strategy. The industry will increase input reasonably and ensure the sustainable development of the breeding industry under the precondition of controlling risk. The feed industry will expand capacity and market share through the construction of new factory of dongguan company and the renovation of existing equipment of gaoling company.

- Q: What equipment does the production of feed premix need?

- Big mixing machine, small premixed machine a, mill a (look), and so on and some necessary machinery and equipment, we also do this, you give some points!

- Q: What kind of equipment does the grain feed use?

- First, the feed material is crushed (2.2 mm) by the mill, and after the grinding, the key step of the particle is to be mixed according to the formula. Formation of granules: the feed mixers make steam modulation to the mixed feed, and then the granulator is pressed by the granulator. Particle cooling: the newly emerged particles are very hot (60-90) and must be cooled by a cooler. Fully formed: when cooled to room temperature, sieve out the powder and the rest is the grain feed you need. Generally speaking, three devices are needed: the tuner, the granulator, and the cooler.

- Q: What kind of equipment is needed for the processing of 100 fragrant pulp for cattle feed

- The dehydration rate of mechanical desiccation can easily be reduced to less than 14% of the water, and the object can be shattered when the object contains less than 14% water.

- Q: The price of complete equipment for large animal feed machinery

- The large and medium-sized whole feed equipment adopts the computer to measure the ingredients automatically, the accuracy of the ingredients is good, the mechanization and the automation degree are high. The design standard complete feed project is the best technology plan, closely following the domestic and international development trend.

- Q: Method of crushing of feed mill

- chop saws: use two toothed and rotational speed of different roller surface will chop material, its advantage is easy to dig thickness degrees, less power, storage, suitable for processing grain materials, bread slag, etc.

- Q: I want to run a small pig feed processing plant in the countryside, I don't understand the technology can do?

- Technology is not the problem, because there are premixed LiaoChang, they will provide you with technical support, you use their one percent premix, they will give you a recipe, contact me if you need any technical support can I have a few friends is good for big do formula feed company. The second device is not a problem, and thousands of dollars can be sold to hybrid machines. The cost of raw materials from 20 tons to 30 tons per month is about 4, 000 to 4, 500 yuan per ton, which is 45 000 yuan per dozen, plus no more than 60,000 yuan. But in operation you may be able to sell on credit, so it is impossible to estimate that if you don't sell it on credit, it will be enough. And then there's your business license, which is the hardest thing to do. It's not convenient here. Friend me. And if you can help me, give me the best answer, I'm doing the task, thank you.

- Q: What is the price of a machine that processes straw feed? Specifications? The more detailed, the better

- The size of the feed is 32 * 32 * 20mm - 80mm, which can satisfy the need of ruminant for coarse fiber and compare science. It is easy to use and can be used in conjunction with fine feed or other coarse materials. Either dry or wet. In particular, it is more convenient to supply scale farms, isolated farms and grazing pastures. Nutrition is rich. At present, there are corn stalks, straw, wheat straw, peanut seedlings and alfalfgrass.

- Q: How much is the machine for the corn stalk processing feed

- Production process: The straw granulator is the main raw material of crop straw or wood chip, and it is compressed into a cylindrical particle by a straw granule machine. Depending on the quality of the raw material, the particles that are pressed can be used as biomass fuel and as feed for livestock and poultry.

Send your message to us

wood pellet mill wood pellet making machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches