PE, PP, PVC And Wood Plate Extrusion Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 1.wooden case 2.by requirements |

| Delivery Detail: | 65 days |

WPC extrison line:

It adopts special design of screw & barrel, mould and extruder for wood plastic products.CNBM company

products series:One step way thick board extrusion line,One step way WPC profile extrusion line;WPC pelletizing extrusion line and different kinds of WPC mould.

The WPC products can be produced by two step extrusion machine, or pelletzing first then through extrison machine, it will save power and place,it has some feature: high output,stable extrusion pressure,high plastication, and good mixing. Optimized screw design have small cutting strength, and it is not easy to cut wood fibre, good plastication.

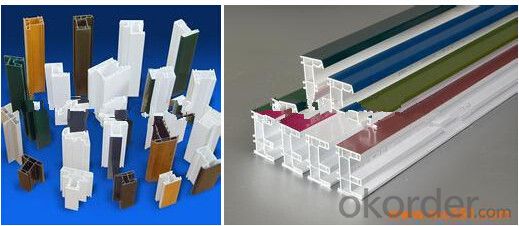

This extrusion line can produce PE,PP or PVC WPC profile products,Main application is for wood tray, indoors and outdoors floor,and outside decoration,and so on.

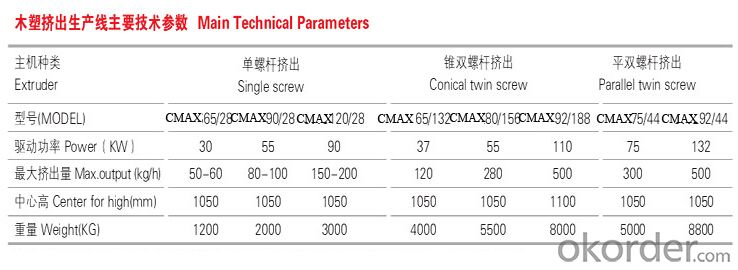

Techinical parameters:

Product show:

All Key parts: screw&barrel,melt pump, screen changer, mold, and downstream equipment are made by Jwell factory!

- Q: What is the adjustment method of China's extrusion machine die?

- (4) lamp alignment: suitable for polythene plastic wires and cables. Use light to illuminate the insulating layer and sheath, observe the upper, lower, left and right sides of the thickness, adjust the screw to the die until it is even, then screw the screws.

- Q: Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- See section - cross section. Setting adjustment with RPC

- Q: Is the extruder the same as the extruder?

- The extruder is also called in the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products.

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Tensile strength is divided between longitudinal and transverse, and PE bags are transversely increased, available 8CLLDPE is added, longitudinal can be added to medium, medium density or high-density material to increase tensile strength.

- Q: The working principle of an extruder

- The material is moved forward by the extrusion of the screw and the barrel, and the material is fully homogeneous and plasticized in the process of material advance. Then the material is extruded by a certain shape of the die by the die of the die.

- Q: Now I want to do it How to change the equipment, please help tell your heroes ah!Used to do PVC pinch plate, now changed to PVC threading tube

- If you want to change, it is best to find the original purchase of equipment manufacturers, so that they change for you.

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

Send your message to us

PE, PP, PVC And Wood Plate Extrusion Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords