Aluminum PE Color Paint Coated Aluminum Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

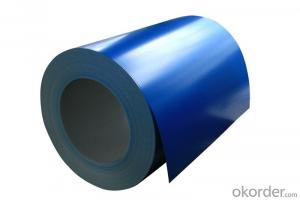

Color coated aluminum coil isa material with excellent acid-resistance and alkali-resistance. The coating layeris even with bright color to last for a very long time. It is a greendecoration material with the characters of environment protection,flame-resistance, and groovy colors. In nowadays, the color coatedaluminum coil has become the popular material for top grade decoration. With our advance professional aluminum coated technique, wecan custom various aluminum coils ,like coated aluminum coil , Color coatedaluminum coil , embossed aluminum sheet with the color and size which youdemands.

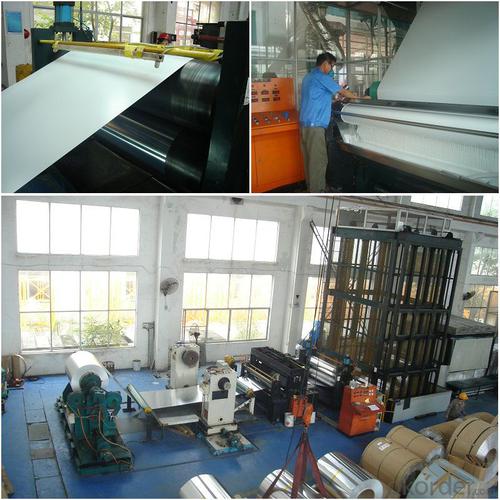

1)Process: pre-treatment, continuous painting and baking for times .

2)Material: high quality material, aluminum sheets from South West AluminumIndustry Company in China, pre-treatment material from Henkel & Chemtellfrom Germany, more than 70% of PVDF coating from PPG Corp., the USA andpolyester from Sweden Becker Industrial Coating Co., Ltd.

3) Ourproducts can keep excellent quality and stability.

4)Thickness: 0.06 - 1.0mm; width: 20 - 1,590mm

Applications:

The aluminum coils are widely used in ACP/curtainpanel/honey comb panel/shutter/roofing and most of the decoration areas. Withthe superior quality and advanced management, our products had been export toEuro/North America /East Asia and many other areas and countries.

PEAluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: Does aluminum undergo corrosion when exposed to seawater?

- <p>Aluminum does not typically corrode in seawater due to its natural protective oxide layer. When exposed to air or water, aluminum forms a thin, dense layer of aluminum oxide on its surface, which prevents further corrosion. This passive layer makes aluminum highly resistant to corrosion in most environments, including seawater. However, under certain conditions such as in the presence of certain chemicals or extreme pH levels, the protective layer can be compromised, leading to corrosion. Generally, though, aluminum is considered a good material for marine applications because of its corrosion resistance.</p>

- Q: Explain the distinction between aluminum as a pure element and its alloys.

- <p>Aluminum is a lightweight, silvery-white metal found in the Earth's crust. It is a pure element with the symbol Al and atomic number 13. Aluminum alloys, on the other hand, are mixtures of aluminum with other elements such as copper, magnesium, manganese, and silicon. These alloys are created to enhance certain properties like strength, durability, and resistance to corrosion. While pure aluminum is soft and malleable, its alloys are stronger and more versatile, making them suitable for a wide range of applications from aerospace to construction.</p>

- Q: Is it possible to utilize recycled aluminum in the production of new products more efficiently than current methods?

- <p>Yes, recycled aluminum can be used more effectively in new products than before. Advances in recycling technology have made it easier to purify and refine aluminum from various sources, including post-consumer waste. This not only conserves natural resources but also reduces energy consumption compared to mining and processing raw bauxite. Additionally, the circular economy approach promotes the design of products that are easier to disassemble and recycle, further enhancing the efficiency of using recycled aluminum in new products.</p>

- Q: This question asks about the impact of adding silicon to aluminum alloys on their characteristics.

- <p>Adding silicon to aluminum alloys significantly enhances their properties. Silicon increases the alloy's strength and hardness, making it more durable. It also improves the alloy's resistance to corrosion, particularly in harsh environments. The addition of silicon can also reduce the melting point of the alloy, which can be beneficial for casting processes. However, it should be noted that excessive silicon content can lead to a decrease in ductility and workability of the alloy. Overall, silicon is a common alloying element used to improve the mechanical properties and performance of aluminum alloys in various applications.</p>

- Q: What are the various applications of aluminum oxide in different industries and daily life?

- <p>Aluminum oxide, also known as alumina, has a wide range of applications due to its hardness and other properties. It is used as an abrasive in products like sandpaper and grinding wheels. In the electronics industry, it serves as a substrate for semiconductor devices. It's also a key component in the production of aluminum metal through the Hall-H茅roult process. In the medical field, aluminum oxide is used in dental materials and as an antiperspirant. Additionally, it's found in cosmetics, ceramics, and as a catalyst in various chemical processes.</p>

- Q: This question asks if there is a risk of lead contamination from old aluminum cans when they are recycled into new food containers.

- <p>There is no risk of lead leaching from old aluminum cans into food during recycling. Aluminum cans are made of aluminum and do not contain lead. The recycling process involves melting and re-forming the aluminum, which effectively removes any potential contaminants. Lead was used in some can linings in the past, but modern food cans are lined with non-toxic materials. Therefore, recycled aluminum cans pose no lead leaching risk to food safety.</p>

- Q: This question asks for methods to protect aluminum from corrosion.

- <p>Aluminum corrosion can be prevented through several methods. One common approach is anodizing, which involves applying a protective oxide layer to the aluminum surface. This process enhances the metal's resistance to corrosion. Another method is using protective coatings such as paints or enamels that act as a barrier against corrosive elements. Cathodic protection, where aluminum is connected to a more easily corroded metal, can also be used. Additionally, ensuring proper design and avoiding contact with aggressive chemicals can minimize corrosion. Regular maintenance and inspection can help detect and address corrosion issues early.</p>

- Q: Describe the process of aluminum oxide formation in a few sentences.

- <p>Aluminum oxide forms through a process known as oxidation, where aluminum reacts with oxygen in the air. This reaction is typically exothermic and can occur at room temperature, especially in the presence of moisture. When aluminum is exposed to oxygen, it forms a thin, protective layer of aluminum oxide on its surface. This layer prevents further oxidation and is what gives aluminum its corrosion resistance. In industrial settings, aluminum oxide can also be produced through electrolysis of aluminum oxide dissolved in molten cryolite.</p>

- Q: Is it possible to enhance the efficiency of solar panels by utilizing aluminum?

- <p>Yes, aluminum can be used to improve the efficiency of solar panels. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which can help in dissipating heat and maintaining optimal operating temperatures for solar cells. It is also used in the manufacturing of solar panel frames, providing structural support while reducing the overall weight of the panels. Additionally, some research suggests that using aluminum in the backsheet of solar panels can enhance their durability and efficiency. However, the extent of efficiency improvement depends on various factors, including the specific design and manufacturing process of the solar panels.</p>

- Q: This question asks for recent applications of aluminum in contemporary society.

- <p>Aluminum has found new uses in modern society across various sectors. In the automotive industry, it is used to manufacture lightweight vehicles for fuel efficiency and reduced emissions. In construction, aluminum is utilized for building facades, window frames, and roofing due to its durability and low maintenance. The aerospace industry also relies on aluminum for aircraft construction because of its strength-to-weight ratio. Additionally, aluminum is used in electronics for heat sinks and casings, and in the packaging industry for food and beverage cans. It's also gaining traction in the energy sector, particularly in battery technology for electric vehicles and renewable energy storage solutions.</p>

Send your message to us

Aluminum PE Color Paint Coated Aluminum Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords