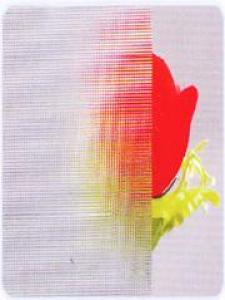

Patterned Glass-Chinchilla

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Patterned Glass is a kind of decorative translucent flat glass with embossed patterns on one or both surfaces. With the special properties of decorations, patterned glass can fully allow the light to pass through and on the other hand it can limit or prevent a clear view effectively, leading to a good "secret" result and a beautiful decorative effect.

Features:

1. Diversified and colorful patterns including Karatachi, Flora, Mistlite, Nashiji, Kasumi, Chinchilla, Moran, Aqualite, Masterlite, Millennium, Raindown, etc.

2. Distinctive and original design.

3. Stereoscopic effects and never-fading patterns.

4. Easy to be processed (cutted, ground, drilled, tempered, laminated, screen-printed, etc.)

Patterns for you to choose from:

Karatchi, Flora, Muro/Mora, Mistlite, etc.

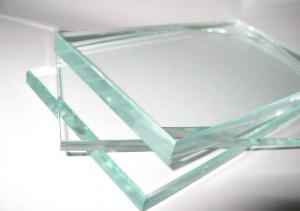

Specifications:

Thickness: 3-5.5mm

Size: customized size

Applications:

- Q: What kind of material is glass made of?

- 1. ingredients, according to the design of the material sheet, weighing all kinds of raw materials, mixing in a mixing machine evenly. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and so on.2., melting, the raw materials will be prepared by high temperature heating, forming a homogeneous bubble free liquid glass. This is a complex process of physics and chemistry. The melting of glass is carried out in a furnace. There are two main types of Furnaces: one is a crucible kiln, the other is glass in the crucible, and the other is heated outside the crucible. The small crucible kiln has only one crucible, and the larger one can be more than 20 crucibles. The crucible kiln is made by gap type, and now only optical glass and color glass are produced by crucible kiln. The other is the tank furnace. The frit is molten in the bath, and the flame is heated on the upper part of the glass. The glass melting temperature mostly in the 1300~1600 C Eve joy. Most of them are heated by flame and a few are heated by electric current. They are called electric furnaces. Now, the pool kiln is continuous production, small pool kiln can be a few meters, big can be more than 400 meters, 2.3. forming the molten glass is converted into a solid product with a fixed shape. The process must take place within a certain temperature range. This is a cooling process. The glass is first converted from a viscous liquid to a plastic state, and then to a brittle solid. The forming method can be divided into two categories: manual forming and mechanical forming.

- Q: I want to ask, if the home is already hollow glass, that still need to foil it?

- In the selection of insulating glass raw materials, enterprises one-sided pursuit of profit maximization, resulting in unstable quality of raw materials. Such as sealant is one of the main raw materials of insulating glass, it directly affects the energy-saving effect and service life of insulating glass, but the low price inferior sealant material is still in mass production.

- Q: Is it a vacuum cup with fluorine coating that affects the health?

- Fluorine is a nonmetallic chemical element, chemical symbol F, atomic number 9. Fluorine is the halogen elements of a periodic system of A VII family, located in the second period in the periodic table of elements.

- Q: Acrylic plexiglass rod can be used in what way?

- Adhesive: two components. One component and two components, such as adhesive and epoxy resin; one component, such as CCl3 (Lv Fang). A two-component adhesive through curing reaction to achieve bonding, one component adhesive is a volatile solvent and finally realize bonding. The two component adhesive is characterized by good bonding effect, no bubbles, no white and strong strength after bonding.

- Q: Can the toughened glass be cracked by the sun?

- thermal stabilityTempered glass has good thermal stability, can withstand the temperature difference is 3 times of ordinary glass, can withstand the temperature difference of 300 degrees celsius.

- Q: Is glass steel pipe used for re examination?

- Before the start (the conditions have started the construction permit (data): the construction unit construction organization design (provided), including the report of the examination table, the examination table), commencement report (Commencement approval), engineering geological survey report, the construction site quality management inspection record (Trial), the quality of personnel qualification certificates (collection aproval), special trades license (collection report), measurement line (Trial)

- Q: What kind of material is the glass made of? Is the price relative to the quality?

- The main raw material of silicon dioxide, the price is related to the quality

- Q: Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- The cooling process of tempered glass is the glass internal pressure generated quickly and uniformly high stress and uniform DB toughened glass broken small particles (tempered glass inner stress is greater than or equal to 90 kg / cm2)

- Q: Samsung LCD panel information

- This screen is indeed the original Samsung screen, Samsung Electronics, Tianjin Corporation assembly production.TSEC is the sign of Tianjin's samsung. So he wrote the MADE IN CHINA (TSEC) behind him

- Q: What's the difference between crystal and ordinary glass?

- Gloss: turn a high grade crystal glass against the light, and you will find it like a beautiful handicraft. White, glittering and translucent, and reflects the charming multicolored light, and low-end crystal or ordinary glassware in these areas there will be a big gap. What's more, in some ordinary glass containers, there are a lot of bubbles, and the color will be dirty and dark.Purchase of crystal glass

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1999 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 55.00% Domestic Market 10.00% Mid East 5.00% Western Europe 5.00% Africa 5.00% Southeast Asia 3.00% South Asia 3.00% Eastern Asia 3.00% Eastern Europe 3.00% South America 3.00% North America 2.00% Southern Europe 1.00% Northern Europe 1.00% Central America 1.00% Oceania |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin, Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Patterned Glass-Chinchilla

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches