Passenger Hoist with Model of SC100/100 with 1 Ton per Cage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SC100/100 Desription

Type: Elevators

Place of Origin: Shandong, China (Mainland)

Model Number: SC100/100

Usage: Construction elevator

Drive Type: Rack & Pinion

Elevator Type: Passenger Elevators

Condition: New

Power Source: Electric

Sling Type: Cable

Maximum Lifting Weight: 2*1000KG

Maximum Lifting Height: 150M

Lift Speed: 0-40m/min

Certification: GOST,ISO

Warranty: One year

SC100/100 Features

SC100 Series construction hoist has a full set of safety protection device. It is equipped with the anti-dropping tripper and short circuit protection, upper and lower limiter and the limit switch of the cage to ensure the safe operation of the hoist; transmission device adopts double motors, double speed reducer to make sure the elevator running smoothly and comfortable; electrical wiring is simple, convenient operation and maintenance, low failure rate.The construction hoist is widely used in building construction and other fields, such as industrial and civil construction, bridge construction, underground construction, large chimney construction and shipbuilding and other places, the use of vertical transport materials and personnel, as a permanent or semi-permanent elevator can be used for warehouse, tower and different occasions.

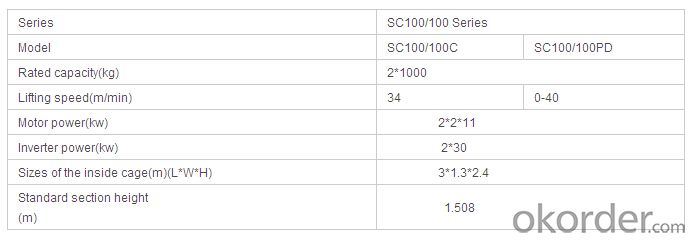

SC100/100 Specifications

SC100/100 Pictures

SC100/100 FAQ

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition.

There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Explain the distinctions between electric and manual building hoists, focusing on their operation, efficiency, and use cases.

- <p>Electric building hoists are powered by electricity and offer faster operation, greater efficiency, and the ability to lift heavier loads. They are ideal for large-scale construction projects where rapid movement of materials is necessary. In contrast, manual hoists are operated by hand and are typically smaller, more portable, and require human effort to lift materials. They are suitable for smaller projects or where power supply is limited. Electric hoists are more automated and can be controlled remotely, while manual hoists require constant physical effort and are less efficient in terms of speed and load capacity.</p>

- Q: Is it possible to utilize a building hoist for the purpose of moving materials up and down in a warehouse setting?

- <p>Yes, a building hoist can be used to lift and lower materials in warehouses. These hoists are designed for vertical transportation of goods and are particularly useful in multi-story warehouses where space is limited. They are capable of handling heavy loads and can be operated manually or with electric power, making them efficient for moving materials between different levels of a warehouse. However, safety measures and proper maintenance are crucial to ensure the secure and effective operation of the hoist.</p>

- Q: Is the construction elevator a special equipment

- The construction elevator is special equipment, the installation and demolition of the special construction plan, after the installation, the special equipment can be tested and qualified for use

- Q: This question asks about the typical issues encountered when constructing a building hoist and the methods to address these problems.

- <p>Common problems in building hoists include mechanical failure, safety hazards, and improper installation. Solutions involve regular maintenance to prevent mechanical issues, strict adherence to safety protocols to mitigate hazards, and professional installation to ensure the hoist is correctly set up. Additionally, using modern technology for monitoring and control can help to identify and rectify problems early. Ensuring proper training for operators is also crucial for the safe and efficient operation of building hoists.</p>

- Q: This question asks for the steps or methods to fix a building hoist that is not working properly.

- <p>To repair a malfunctioning building hoist, first, ensure the hoist is powered off and disconnected from any power source to ensure safety. Inspect the hoist for visible damage or loose parts. Check the motor, cables, and control panel for any signs of wear or damage. If the issue is mechanical, such as a stuck cable or a jammed pulley, disassemble the affected parts and clean or replace them as necessary. For electrical issues, inspect the wiring and connections for any shorts or breaks. Consult the hoist's manual for troubleshooting guides specific to the model. If the problem persists or if you're unsure about any steps, it's best to contact a professional technician for repair to avoid further damage or safety hazards.</p>

- Q: 6 layer of brick and concrete construction project, have tower crane still need construction elevator?

- 6 floors of brick and concrete construction projects, tower cranes do not need construction elevator. Brick structure refers to the building of the wall of vertical bearing structure, column, etc. By using brick or block masonry, lateral load-bearing beam, reinforced concrete structure is adopted for floor, roof boarding, etc. In other words, the masonry structure is a small amount of reinforced concrete and most brick wall bearing structures. The masonry structure is a kind of hybrid structure, which is composed of brick wall and reinforced concrete beams. Suitable for small width and depth, room area is small, multilayer or low-rise buildings, for load bearing walls can't change, while the frame structure of wall body can be altered.

- Q: Is it possible to use a lifting device to lift objects that are heavier than its specified maximum load?

- <p>No, a lifting device should never be used to lift objects that exceed its rated load capacity. Doing so can lead to catastrophic failure of the device, potentially causing serious injury or death. Always adhere to the manufacturer's specifications to ensure safety and prevent accidents. Overloading a lifting device can result in structural damage, compromised safety mechanisms, and increased risk of collapse or dropping the load. It is crucial to respect the load limits to maintain the integrity and reliability of the lifting equipment.</p>

- Q: This question asks for guidelines on the safe operation of a building hoist, a device used to lift materials in construction.

- <p>To use a building hoist safely, follow these guidelines: Ensure the hoist is properly installed and inspected by a qualified person. Never exceed the hoist's weight limit. Keep the hoist area clear of obstacles and ensure all safety devices are functioning. Do not use the hoist if there are any visible defects or damage. Always secure the load properly and ensure it is balanced. Never leave the hoist unattended while in operation. Use hand signals or a communication system to coordinate with the operator. Regularly inspect and maintain the hoist to prevent accidents. Always follow the manufacturer's instructions and adhere to local safety regulations.</p>

- Q: This question asks about the precautions and safety protocols that should be followed when using lifting equipment in construction projects.

- <p>Safety measures for using lifting equipment in construction work include regular inspections and maintenance of the equipment, ensuring all safety features are in place and functioning correctly. Operators must be trained and certified for the specific type of lifting equipment they are using. Load limits should never be exceeded, and all loads must be secured properly. Safe operating procedures should be followed, such as not lifting loads over people and maintaining a safe distance from power lines. Personal protective equipment (PPE) must be worn by operators and workers in the vicinity. Emergency procedures should be established and communicated to all workers. Regular safety briefings and training sessions should be conducted to keep safety at the forefront of all operations.</p>

- Q: Construction site construction elevator and tower crane, which unit security check and acceptance?

- Different but most likely is the construction elevator

Send your message to us

Passenger Hoist with Model of SC100/100 with 1 Ton per Cage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords