construction hoist SC100 single cage lifting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SC100 Single Cage Construction Hoist Description

Feature: Construction Hoist

Condition: New

Application: Construction

Payload(kg):1000

Lifting Speed(m/min):33

Motor Power(kw): 2*11

Safety Device: SAJ30-1.2

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC100

Packaging & Delivery of SC100 Single Cage Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of SC100 Single Cage Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

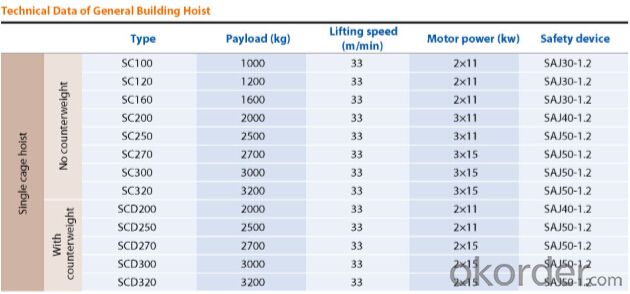

SC100 Single Cage Construction Hoist Specifiction

FAQ of SC100 Single Cage Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

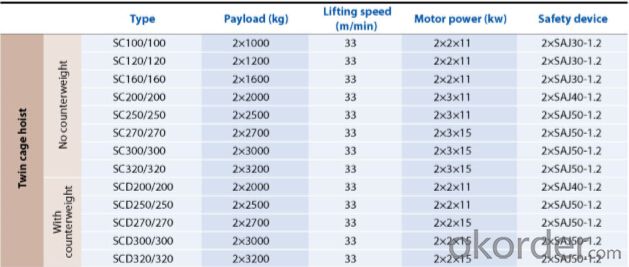

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for an explanation of the different types of building hoists used in construction.

- <p>Building hoists, also known as construction hoists or material hoists, are essential for moving materials and personnel in high-rise construction projects. The main types include: 1. <strong>Freestanding Hoists</strong>: These do not require a building structure for support and are self-supporting. 2. <strong>Cladding Hoists</strong>: Attached to the building's facade, used for moving materials during cladding work. 3. <strong>Personnel Hoists</strong>: Specifically designed for transporting workers, ensuring safety with features like cages and safety devices. 4. <strong>Material Hoists</strong>: Built to transport heavy construction materials and are robust and durable. 5. <strong>Electric Hoists</strong>: Operated by electricity, offering precise control and energy efficiency. 6. <strong>Hydraulic Hoists</strong>: Utilize hydraulic systems for lifting, known for their smooth operation and heavy load capacity. Each type serves a specific purpose and is chosen based on the project's requirements and the stage of construction.</p>

- Q: Do the elevator need to be installed when the main project is in construction

- In the construction of the main body, the construction elevator should be installed. The general construction is about 15 meters. The construction elevator is commonly called the construction elevator, but the construction elevator includes a broader definition and the construction platform belongs to the construction elevator series. Simple construction elevator is by car, driving mechanism, standard section, attached to the wall, chassis, fence, electrical system and so on several parts, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction elevator is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. The construction elevator of our country is more and more mature, and gradually goes to the international. 3, building main body engineering means based on the above foundation, accept, for all the top load and construction project, maintaining structural integrity, stability and safety of bearing structure system.

- Q: Where is the location of the elevator in the project

- The position of construction elevator is usually set in the project to facilitate access to material, material handling and personnel up and down, not affecting the construction process.

- Q: What is the highest weight a building hoist can safely lift?

- <p>The maximum load capacity of a building hoist can vary significantly depending on the specific model and design. Generally, capacities range from 500 kg to 3,000 kg or more. It's crucial to refer to the manufacturer's specifications for the exact load capacity of any given hoist. Overloading a hoist can lead to accidents and damage, so it's essential to operate within the specified limits.</p>

- Q: This question asks whether a building hoist can be utilized for lifting both fragile and non-fragile items.

- <p>Yes, a building hoist can be used for lifting both fragile and non-fragile objects. However, it is crucial to ensure that the hoist is equipped with the appropriate attachments and safety measures to handle fragile items without causing damage. For non-fragile objects, the hoist can be used more freely, but still, safety protocols must be followed to prevent accidents. The key is to use the hoist within its weight capacity and to adhere to all operational guidelines to ensure the safe and effective lifting of all types of objects.</p>

- Q: Is it possible to utilize a single-rope lifting system in the context of a building hoist?

- <p>Yes, a single-rope lifting system can be used in a building hoist. This system is common in construction elevators, where a single rope is used to lift and lower the hoist's cage. The rope is attached to a motor at the top and passes over sheaves or pulleys to provide mechanical advantage. It is essential to ensure that the rope is strong enough to support the load and that the system is equipped with safety features such as overload protection and emergency braking mechanisms to prevent accidents.</p>

- Q: Is it possible to utilize a hydraulic cylinder in the construction of a building hoist?

- <p>Yes, hydraulic cylinders can be used in building hoists. They are often employed in lifting systems due to their ability to generate large forces in a controlled manner. Hydraulic cylinders provide smooth and precise control over heavy loads, which is crucial for the safe and efficient operation of a building hoist. They can handle the vertical movement of materials and personnel in construction settings, ensuring a stable and reliable lifting mechanism.</p>

- Q: Explain the distinctions between electric and electric-motorized building hoists.

- <p>Electric building hoists are powered by electricity and typically use a motor to lift and lower loads. They are designed for vertical transport of materials in construction settings. Electric-motorized hoists, on the other hand, are a specific type of electric hoist that emphasizes the use of an electric motor for operation. The primary difference lies in the level of automation and control. Electric-motorized hoists often have more advanced features like variable speed control and may be integrated into larger systems for automated material handling. Both are efficient, but electric-motorized hoists offer higher precision and control, making them suitable for more complex applications.</p>

- Q: Helped wall bar how to set up, and several layers of set a, two width, wall rod need a few meters long, what shape is the embedded parts, how much of a steel bar, Angle and wall vertical or have?

- According to drawings, find the embedded at the scene near the level of architectural axis positioning and high elevation line (50 wire or 1 m wire) location and double-check, axis dividing levels as much as possible in accordance with the size distribution. Find out after each axis, measuring building contour, and map measure the buildings, and building construction drawing contrast, timely transfer measurement results to the designer, designer analyze the error and make changes

- Q: This question asks for a description of the process of using a hydraulic cylinder in the context of a building hoist.

- <p>To use a hydraulic cylinder in a building hoist, first ensure the hoist is properly installed and secured. Connect the hydraulic cylinder to the hoist's power source, typically a hydraulic pump. The pump pressurizes hydraulic fluid, which is then directed into the cylinder. As the fluid enters, it pushes a piston within the cylinder, causing it to extend and lift the load. To lower the load, the fluid is released from the cylinder, allowing the piston to retract. Always monitor the pressure and ensure the system is leak-free for safe operation. Regular maintenance, including checking seals and lubricating parts, is crucial to prolong the life of the hydraulic cylinder and ensure efficient hoist performance.</p>

Send your message to us

construction hoist SC100 single cage lifting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords