Passenger Hoist with Model of SC160/160 with 1.6 Ton per Cage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SC160/160 Desription

Type: Elevators

Place of Origin: Shandong, China (Mainland)

Model Number: SC160/160

Usage: Construction elevator

Drive Type: Rack & Pinion

Elevator Type: Passenger Elevators

Condition: New

Power Source: Electric

Sling Type: Cable

Maximum Lifting Weight: 2*1600KG

Maximum Lifting Height: 150M

Lift Speed: 0-40m/min

Certification: GOST,ISO

Warranty: One year

SC160/160 Features

The SC200/200Construction Elevator is an external construction hoist with a three- drive rack-and-pinion mechanism. It has a rated loading capacity of 2 tons and a rated hoisting height of 150 meters. A simple alteration can change it into a single-cage construction elevator with a rated loading capacity of two tons. The SC200/200Construction Elevator is equipped with a state-patented safety device which can brake automatically in case of accidental fall. The driver element on top of the cage is safe and reliable and convenient for maintenance. The elevator with a maximum hoisting height of 300 meters is widely used for construction work such as industrial and civil construction, bridge construction, underground mining, large chimney construction and the shipping industry. It can be used for transporting materials or people vertically, as a permanent or half-permanent lift, or in places like storehouses and tall towers.

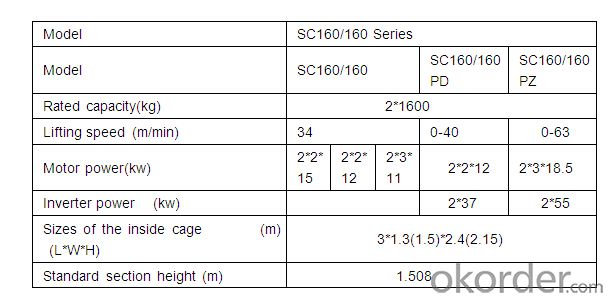

SC160/160 Specifications

SC160/160 Pictures

SC160/160 FAQ

Q: How can we calculate how many mast section we need?

A: Mast section height is 1.508m, you can use the client’s building’s total height divided by the height of mast section, and you will get the quantity of mast section.

Q: How many tie-ins are needed?

A: The tie-in is the linked part between mast and building and it is used to keep the stabilization of the mast. Distance between the tie-in is about 6~9m.

- Q: This question asks for the method to adjust the tension of ropes or cables in lifting equipment such as a building hoist.

- <p>Adjusting the tension on ropes or cables in lifting equipment like a building hoist involves several steps. First, ensure the equipment is turned off and secured to prevent any accidents. Then, locate the tensioning mechanism, which could be a ratchet, turnbuckle, or a similar device. Gradually adjust the mechanism to tighten or loosen the cable as needed. Use a tension meter to measure the tension and ensure it meets the manufacturer's specifications. Regularly inspect the cables for wear and damage, and replace them if necessary. Always follow the equipment's manual for specific instructions and safety guidelines.</p>

- Q: This question asks for the methods used to maintain and care for a building hoist, which is a type of lifting equipment used in construction.

- <p>Regular maintenance of a building hoist is crucial for safety and efficiency. Key methods include daily inspections of cables, hooks, and safety devices for any signs of wear or damage. Lubricate moving parts as per the manufacturer's guidelines to reduce friction and prevent rust. Ensure that all electrical components are clean and dry, and check for any loose connections or damaged wires. Perform load tests periodically to confirm the hoist's lifting capacity and safety. Keep the control panel and all operational areas clean and free from debris. Regularly check the hoist's anchorage to ensure it is secure. Adhere to all manufacturer's recommendations for maintenance intervals and procedures. Proper maintenance can extend the life of the hoist and prevent accidents.</p>

- Q: Is it permissible to use a building hoist for lifting people?

- <p>Building hoists are not designed for lifting people and doing so can be extremely dangerous. They are specifically engineered for the transportation of materials and equipment in construction settings. Using a building hoist to lift people violates safety regulations and can result in severe accidents. Always adhere to the manufacturer's guidelines and local safety laws, which prohibit the use of building hoists for carrying personnel.</p>

- Q: This question asks about the measures taken to guarantee the safety and reliability of lifting equipment prior to its use in construction.

- <p>To ensure that lifting equipment is safe and reliable before using it in construction work, several key steps must be taken. Firstly, regular inspections and maintenance are crucial to identify any potential issues or wear and tear. Secondly, all equipment should be thoroughly tested and certified by qualified personnel to meet safety standards. Thirdly, proper training for operators is essential to ensure they understand how to use the equipment safely. Additionally, having a comprehensive safety plan in place, including emergency procedures, can help prevent accidents. Lastly, using equipment from reputable manufacturers and ensuring all components are in good working order are also vital for maintaining safety and reliability.</p>

- Q: This question asks for the process of changing the speed at which a building hoist cylinder operates.

- <p>Adjusting the speed of a building hoist cylinder involves several steps. First, ensure the hoist is turned off and disconnected from power. Check the manual for the specific model to understand the speed control mechanism, which could be a variable frequency drive (VFD), a governor, or a throttle control. If it's a VFD, adjust the frequency setting to increase or decrease speed. For a governor, you might need to change the spring tension or adjust the control valve. With a throttle control, simply turn the throttle to the desired speed setting. Always test the hoist at low loads first to ensure the adjustments are safe and effective before using it for heavy loads.</p>

- Q: This question asks about the various elements that can influence the efficiency and effectiveness of a building hoist.

- <p>The performance of a building hoist is affected by several factors including the type and weight of materials being lifted, the frequency of use, the hoist's mechanical condition and maintenance, environmental conditions such as wind and temperature, the skill and training of operators, and the design and capacity of the hoist itself. Proper installation, regular inspections, and adherence to safety protocols also play a crucial role in ensuring optimal performance and safety. Additionally, the quality of electrical systems, the efficiency of the drive mechanism, and the structural integrity of the hoist's components can significantly impact its operation.</p>

- Q: This question asks for an identification of the various types of lifting equipment that are specifically utilized in the context of building hoists.

- <p>Different types of lifting equipment used for building hoists include: 1. Electric Chain Hoists, which are versatile and suitable for various lifting tasks. 2. Manual Chain Hoists, that require manual operation and are used for lighter loads. 3. Electric Wire Rope Hoists, known for their high lifting capacity and durability. 4. Air Hoists, which are powered by compressed air and are ideal for environments where electricity is hazardous. 5. Geared Winches, used for pulling or lifting heavy loads with precision. 6. Jib Cranes, which provide a fixed or semi-fixed lifting solution in workshops. 7. Gantry Cranes, used for lifting heavy loads over a specific area. Each type serves specific purposes and is chosen based on the weight, environment, and specific requirements of the construction project.</p>

- Q: This question inquires about the cost of a hydraulic building hoist.

- <p>The cost of a hydraulic building hoist can vary significantly depending on factors such as capacity, brand, features, and new or used condition. Prices typically range from a few thousand dollars for smaller, basic models to tens of thousands for larger, more advanced units. For a precise quote, it's best to contact manufacturers or suppliers with specific requirements, as costs can fluctuate based on the model and market conditions. It's also advisable to consider ongoing maintenance and operational costs when budgeting for a hydraulic building hoist.</p>

- Q: This question asks about the measures taken to ensure that lifting equipment remains safe and functional in various weather conditions.

- <p>To ensure that lifting equipment is safe and reliable in all weather conditions, regular maintenance and inspection are crucial. Equipment should be designed with weather-resistant materials and should be tested periodically to withstand extreme temperatures, humidity, and precipitation. Protective covers or enclosures can be used to shield equipment from the elements. Additionally, training operators on the safe use of equipment in different weather conditions is essential. Emergency procedures should be in place for extreme weather events, and equipment should be regularly checked for wear and tear that could be exacerbated by weather conditions.</p>

- Q: This question asks for the detailed specifications and dimensions of a building hoist, which is a type of construction equipment used to lift materials.

- <p>The specifications and measurements of a building hoist can vary significantly depending on the model and manufacturer. Generally, a building hoist (also known as a construction hoist or material hoist) is characterized by its load capacity, which can range from 500 kg to several tons. The height of the hoist is determined by the number of floors it serves, typically measured in meters. The width and depth are usually around 1.5 to 2 meters, and the speed can vary from 24 to 60 meters per minute. The power requirement is often between 3 to 7.5 kW. Safety features like overload protection, emergency stop, and limit switches are also standard. For precise specifications, it's essential to consult the manufacturer's data sheet for the specific model in question.</p>

Send your message to us

Passenger Hoist with Model of SC160/160 with 1.6 Ton per Cage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords