Particle Board 3/4 Veneer Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

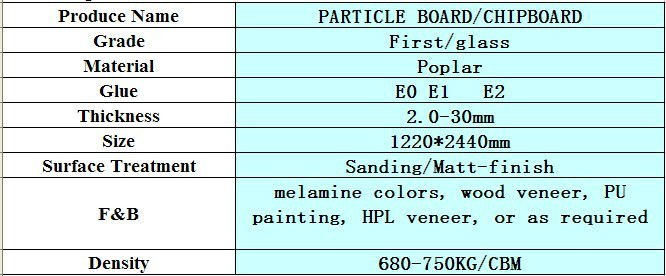

1. Description of Veneer Faced Particle Board

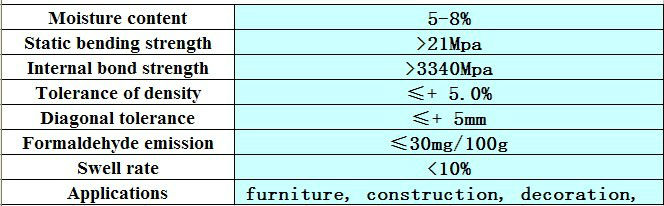

2. Technical Date of Veneer Faced Particle Board

3. Feafures of Veneer Faced Particle Board

(1)Environmental protection. Not fumigation,anti-borer , all reach environmental standards of European E1 is the

preferred health -core doors .

(2) Heat preservation. 40mm thick door by evacuation door core made of wooden doors amount to a brick wall with 300mm .

(3) Sound insulation. 40mm thick door by evacuation door-core made of wooden doors which insulation effect as high as 28db .

(4) Light in weight. Compared to the general solid wood , use tubular structures to reduce the 60% weight of the board .

4. Look forward to your inquiry

We persevere in the management of credit and innovation,and we are willing to cooperate with all the friends for mutual development.

Looking forward to your inquiry and trail order.

- Q: The Particleboard quality identification editor

- Surface smoothness, smoothness point of view, the general factory time to go through the 200 # sandpaper light,

- Q: What is the modeling technology department?

- Hot-forming method mainly produces furniture accessories, interior decoration accessories and pallets and other products,

- Q: Particleboard industry is currently looking ahead

- and more attractive is the new technology without glue, it appears Will fundamentally change the particleboard industry.

- Q: Particleboard in the production process of environmental performance

- to be stored for some time after the observation room. If no spiky smell that particleboard release of formaldehyde less, the use will not affect human health

- Q: What is the production process of particleboard

- it is beneficial to improve the bending strength, tensile strength and surface finish, and reduce the possibility of slag stratification in the relief.

- Q: Raw materials for the production of particleboard include

- Preparation of wood shavings processing equipment are chipper, re-crusher, grinding machine and fiber separator, cutting methods are cutting, cutting and broken.

- Q: From the appearance point of view

- moisture resistance of wood-based panels depends on its density and moisture-proof agent, soaked in water

- Q: Production of raw materials for particleboard

- Processed into sheet, strip, needle, granular wood, shavings, wood, sawdust, etc., said broken material. I

- Q: What types of particleboard can be divided into?

- bending strength, vertical plate tensile strength (internal strength), grip nail force elasticity Modulus and modulus, etc

- Q: According to the use of points: Class A particleboard; Class B particleboard

- According to the use of raw materials: wood particleboard; bagasseboard particleboard; linseed particle board; cotton stalk particle board; bamboo particle board; cement particle board; gypsum particleboard.

Send your message to us

Particle Board 3/4 Veneer Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords