Painted Glass-3

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

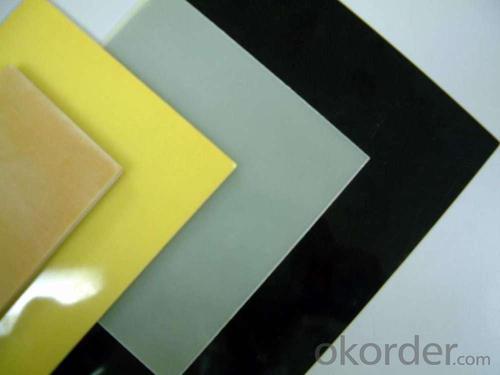

Painting Glass is made by printing ceramic frit on float glass and by melting the colorant into the glass surface in the tempering furnace, in this way painted glass is manufactured with the performance of non-fading and multi-color.

Features:

1、Various colors, stable and durable: Painted glass offers designers a wide range of color possibility, aesthetic value and variety and ceramic frit assures stable color.

2、Energy-saving: Painted glass can reduce air-conditioning cost by insulating solar heat.

3、Light building materials: Painted glass serves as a substitute for stone, tile, metal plate and reduces structural load on the external wall, making glazing easy.

4、High wind pressure resistance: Painted glass can be processed into laminated tempered glass or laminated heat-strengthened glass products.

Specifications:

Thickness: 4-19mm

Max Size: 2500*4500mm

Min Size: 305*305mm

Applications:

Painted Glass is widely used in façade, stained glass for interior partition, automotive glass, furniture and art glass, etc.

- Q: What is the raw material for making glass?

- The 60% component of the crystal is "two oxide" (SiO2). The color of the crystal is due to the addition of two silicon oxide, which also contains a variety of trace metals. In the natural environment, and most of crystal mineral calcite, pyrite, iron ore, Hui various colors of mica, Biqian, granite, Jin Hongshi and other "symbiosis", and formed some suspected imaginary scene, the so-called "different" like crystal, crystal increased collection of fun and value.

- Q: How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- There's no problem with fiberglass mesh.

- Q: Who knows how the types of silicon sand are divided into types and what they are used for?

- The main raw materials for making glass. Generally the sand containing silicon, but in general how much silicon content to differentiate the varieties and quality of silica sand, silica sand with particle size, particle size distribution, particle size distribution is generally good, good quality.

- Q: What is the difference between acrylic board, lotus board, organic board and PVC board?

- Acrylic board is a kind of chemical material. Chemistry called "PMMA" is a polyacrylate, commonly known as "after the special treatment of plexiglass", in the application industry, acrylic raw materials in general in the form of particles, plates, pipes and other forms. Organic glass acrylic and special processing, organic glass products, light boxes with acrylic production has good transparence, pure color, rich colors, beautiful smooth, both day and night of two kinds of effect, long service life, does not affect the use of other features, in addition, acrylic and aluminum plate material, advanced screen printing etc. can be the perfect combination, to meet the business needs of acrylic plastic is to improve the store level business, unified enterprise image of the best form of outdoor advertising.

- Q: Cement / glass raw materials, equipment, principle, composition, characteristics, uses and types

- Ceramic composition used in high melting ceramics is used by manufacturers and is hardly used to make individual ceramic restorations. The material contains 75% to 85% feldspar, 12% to 22% quartz and 4% kaolin. Feldspar forms glass phases, and quartz remains suspended in the form of quartz after sintering. Quartz (SiO2) is used as an intensifier in ceramics. At normal sintering temperature, it has no structural change and plays a role in stabilizing the bulk (mass) at high temperatures.

- Q: How to seal the glass fiber reinforced plastic mould?

- Step up. Concave convex surface or Z face.

- Q: Is glass fiber reinforced plastic board fireproof partition board?

- The most common glass steel products do not need special fire, make fire, i.e. adding flame retardant, but the main raw materials of steel, glass resin itself is flammable, so most glass steel is not good (even if the fire flame retardant, flame retardant) fill much will affect the quality of glass steel products is so the promotion is not too good in fire. Of course, some glass fiber reinforced plastic pipes and other products have also obtained fire certificate, but the actual use is not much.

- Q: Does anyone know iPhone's toughened glass production process? Thank you

- Then the glass (CNC) carved machine milling, drilling, trenching and processing; (quality check)4. followed by ultrasonic cleaning machine cold processing of semi-finished glass cleaning;5., the next step is to carry out the chemical strengthening process and enter the chemical strengthening furnace;

- Q: Is the raw material of organic glass harmful to human body?

- Organic glass is a popular name. From this name you may not know what kind of material it is, nor can you tell what element it is made of.

- Q: Who can tell me the raw material and function of the flashy glass?

- The roll of the roll is rotated, and the glass belt is pulled out of the tin groove into the annealing furnace. After annealing and cutting, the flat glass product is obtained.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; Southeast Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai; Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Painted Glass-3

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches