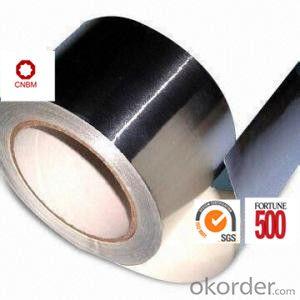

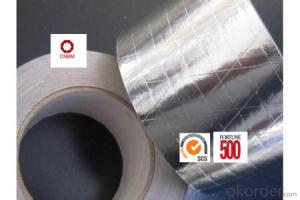

Packaging Tape with Logo - Aluminum Foil Tape Synthetic Rubber Based Good Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

Synthetic Rubber Based Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Synthetic Rubber Based Aluminum Foil Tape: widely used for seaming and jointing bonding of various vapor barriers, fixing thermal fin in refrigerators. Provide fast and permanent bond performance for vapor barrier against the moisture.

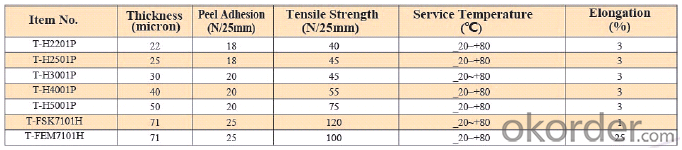

Typical Physical Reports of Synthetic Rubber Based Aluminum Foil Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1200mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Aluminum Foil Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Does packaging tape have a specific weight capacity?

- Packaging tape indeed possesses a specific weight capacity. The weight capacity of packaging tape relies on its thickness, width, and overall quality. Typically, packaging tapes are engineered to effectively seal boxes and packages, with their weight capacity determined by their adhesive strength and resilience. The majority of standard packaging tapes can handle a weight capacity ranging from approximately 20 to 30 pounds. Nonetheless, there are heavy-duty packaging tapes available that can manage weights of 50 pounds or more. It is crucial to take into account the weight of the package or box that requires sealing and opt for a packaging tape that can accommodate the precise weight capacity in order to ensure a secure and dependable seal.

- Q: Are there specific brands of packaging tape that are recommended?

- Certainly, there exist specific brands of packaging tape that are frequently suggested due to their quality and dependability. Noteworthy and highly respected brands encompass Scotch, Duck, 3M, Gorilla, and Uline. These particular brands are renowned for crafting packaging tapes that possess robust adhesive properties, exceptional durability, and the capability to effectively seal boxes and packages. Moreover, these brands frequently provide an array of options, including diverse widths, lengths, and types of tape (e.g., clear, colored, or reinforced), catering to various packaging needs. Nevertheless, it is always advisable to take into account the specific demands of your packaging task and peruse customer reviews prior to settling on a brand of packaging tape.

- Q: What kind of material is used in this kind of tape? What are its features? How are they made? And so on!The more detailed you write, the better!

- Look, there's no poison. Look at the sticky stuff above. What's that?

- Q: Is packaging tape safe to use on plastic hangers?

- Yes, packaging tape is generally safe to use on plastic hangers. It adheres well to most surfaces, including plastic, and provides a secure hold. However, it is recommended to use a moderate amount of tape to avoid damaging or leaving residue on the hangers.

- Q: Can packaging tape be used for sealing plastic containers with liquids?

- Yes, packaging tape can be used for sealing plastic containers with liquids. However, it is important to note that packaging tape is not specifically designed for this purpose and may not provide a completely secure seal. It is recommended to use tape that is specifically designed for sealing containers with liquids, such as waterproof or heavy-duty tape, to ensure a more reliable seal and prevent any potential leaks or spills.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Indeed, plastic pet carriers can be effectively sealed using packaging tape. This tape is specifically created to securely seal packages and boxes, offering a powerful adhesive bond. With proper application, it can successfully seal the entrances of plastic pet carriers, guaranteeing the safety of your beloved pet. Nevertheless, it is crucial to ensure an even and secure application of the tape to avoid any potential gaps or openings through which your pet could escape. Furthermore, it is advisable to periodically inspect the tape's integrity and reapply it if needed.

- Q: As for the title, just bought the tape cutter, but I don't know how to use it. I bought it in plastic. Used for packing express boxes. It's better to use a process chart for me to see.. Thanks。。 Or clear words can also...

- But do not attach the tape to the sealing machine and put it away. There is no machine, or else let you have a look

- Q: How does packaging tape perform in dusty environments?

- Packaging tape typically functions effectively in dusty environments; however, its performance may vary based on the specific conditions and tape quality. The presence of dust particles has the potential to hinder tape adhesion, resulting in reduced stickiness and package security. Nevertheless, most packaging tapes are designed to resist dust and other contaminants, equipped with a robust adhesive backing capable of withstanding moderate levels of dust. To optimize tape performance in dusty environments, it is advisable to select tapes with higher tack or adhesive strength. These tapes are specifically engineered to provide superior adhesion and stickiness, even in dusty conditions. Additionally, choosing tapes with a thicker backing material can prevent dust particles from penetrating the tape and compromising its adhesive properties. It is crucial to note that excessive dust accumulation can still impact the tape's performance, particularly when fine and abundant. In such cases, it is recommended to regularly clean the package surfaces before applying the tape to ensure optimal adhesion. Adequate surface preparation, such as wiping the area with a clean cloth or using compressed air to remove dust, can enhance tape performance in dusty environments. In conclusion, while packaging tape generally performs well in dusty environments, it is important to consider tape quality, dust exposure level, and proper surface preparation to ensure optimal adhesion and package security.

- Q: What is the size of the transparent sealing tape? The length is 50 yards and 100 yards. Is that the meter?

- As for what you mean, 50 yards and 50 meters are not the same thing. The.1 code equals 0.9144 meters

- Q: How do I prevent packaging tape from tearing during application?

- To prevent packaging tape from tearing during application, make sure to use a high-quality tape that is specifically designed for packaging. Additionally, ensure that the surface of the package is clean and dry before applying the tape. Avoid using excessive force while pulling the tape, instead apply it smoothly and evenly. If you're still experiencing tearing, you can try using a tape dispenser or moistening the tape slightly to make it more pliable.

Send your message to us

Packaging Tape with Logo - Aluminum Foil Tape Synthetic Rubber Based Good Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords