Packaging Tape Ghost Directions Paper Masking Tape Manufactured in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Paper Masking Tape Manufactured in China

Interior paint masking, silk screening, Light duty packaging, bundling, holding, splicing &Tabbing, and other non-critical applications where a pressure-sensitive tape is needed.

Size of Paper Masking Tape Manufactured in China

Paper Core ID: 76mm

Jumbo size: 0.99m x 1800m, 1.22m x 1800m, 1.51m x 1800m

Cut roll size: As per customer's requirement

Cut rolls: Shrink package, placed in cartons, with or without pallet

Packing of Paper Masking Tape Manufactured in China

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

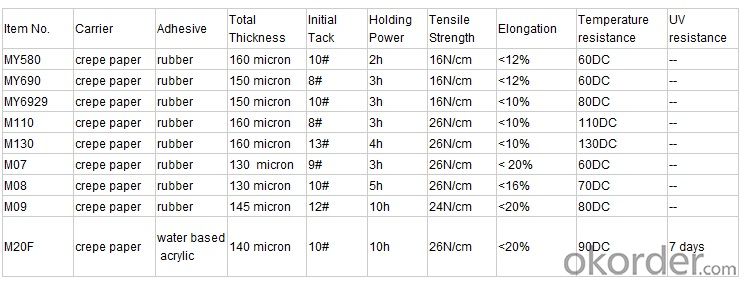

Technical Data of Paper Masking Tape Manufactured in China

Picture Show of Paper Masking Tape Manufactured in China

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape compatible with automatic packaging machines?

- Indeed, automatic packaging machines are compatible with packaging tape. These machines are specifically engineered to function with diverse packaging materials, such as packaging tape. Equipped with efficient mechanisms, these machines proficiently and reliably dispense and apply packaging tape to seal packages. The utilization of packaging tape alongside automatic packaging machines is a common practice to optimize the packaging procedure and guarantee the proper sealing and protection of packages throughout their transportation.

- Q: Can packaging tape be used for sealing packages for shipping?

- Yes, packaging tape can be used for sealing packages for shipping. Packaging tape is specifically designed to securely seal packages and keep them intact during transit. It provides a strong and durable bond that can withstand the rigors of shipping and handling. Whether you are shipping small or large packages, packaging tape is an essential tool to ensure that your items are properly sealed and protected during transportation.

- Q: Selection of tapes

- We live in ordinary packing tape (BOPP BOPP) is the daily necessities for any enterprise, company, individual life indispensable, but compared to a situation at home, although many manufacturers, technology is uneven. Moreover, the technical content of the domestic adhesive tape industry is still in a very low stage, and the country does not have a clear choice. People often know the tape is in a very ignorant stage, think the price is low, feel good viscosity, in fact, these are wrong knowledge and judgment.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Yes, packaging tape can be used for sealing packages with medical or pharmaceutical products. However, it is important to consider the specific requirements and regulations for packaging in the medical and pharmaceutical industries. These industries often have stringent standards for packaging materials to ensure product safety, integrity, and compliance with regulatory guidelines. Therefore, it is recommended to use packaging tape that is specifically designed and approved for medical or pharmaceutical applications. These tapes are typically made from materials that are resistant to moisture, tampering, and provide a strong seal to protect the contents of the package. Using approved packaging tape helps to maintain the quality and integrity of medical or pharmaceutical products during storage and transportation.

- Q: What is the difference between acrylic and hot melt packaging tape?

- Acrylic and hot melt packaging tapes are both commonly used for sealing boxes and packages, but they have distinct differences in terms of their adhesive properties and performance. Acrylic packaging tape is known for its clarity and transparency, making it ideal for applications where the appearance of the package is important. It is also resistant to yellowing and aging, ensuring that the tape remains clear and does not become brittle over time. Acrylic tape has a strong initial tack, meaning it adheres quickly to surfaces upon application. However, it may not perform as well in extreme temperatures, as it can lose its adhesive strength when exposed to high heat or cold conditions. On the other hand, hot melt packaging tape is made from a synthetic rubber adhesive that is applied to the tape as a hot liquid. This type of tape offers superior adhesion and bond strength, making it suitable for heavy-duty or challenging packaging tasks. It has excellent resistance to temperature changes, maintaining its adhesive properties even in extreme conditions. Hot melt tape is also known for its quick and easy release, making it convenient for high-volume packaging operations. In summary, while both acrylic and hot melt packaging tapes are effective for sealing boxes, they have different strengths and weaknesses. Acrylic tape is best for applications where clarity, aging resistance, and initial tack are priorities. Hot melt tape, on the other hand, excels in terms of adhesion strength, temperature resistance, and ease of use. Ultimately, the choice between the two depends on the specific requirements and conditions of the packaging task at hand.

- Q: Is packaging tape suitable for sealing heavy boxes?

- Yes, packaging tape is suitable for sealing heavy boxes.

- Q: What's the ingredient of 610#3m tape?

- 4.2 will ring out from the paint on the surface of the Jie Dao 1/16 "11 parallel lines and vertical ring into the same 11 parallel lines (to quit the paint coating does not hurt the rubber parts as the standard).4.3 test tape affixed to the notch surface (tape ends should be long out scored 1/2 "long, so a finger pressing tape), the internal air and keep no / 90 + 30 seconds.4.4 pull the adhesive tape 180 degrees parallel to the surface of the paint coating.5. judgment:5.1, over 10% of the oil drain is a serious problem.5.2, no grid number, since 5% is a general problem.

- Q: How do I prevent packaging tape from leaving a sticky residue?

- To prevent packaging tape from leaving a sticky residue, there are a few simple steps you can take. 1. Choose the right type of tape: Opt for high-quality packaging tape that is specifically designed to leave minimal residue. Look for tapes with a low-tack adhesive or those labeled as residue-free. 2. Clean the surface: Before applying the tape, make sure the surface is clean and dry. Wipe away any dust, dirt, or grease using a mild detergent or a rubbing alcohol solution. This will help the tape adhere better and reduce the chances of residue formation. 3. Test in a small area: If you're unsure about the tape's residue potential, it's always wise to test it in a small, inconspicuous area first. Apply a small piece of tape and let it sit for a few hours or overnight. After removing it, check if any sticky residue is left behind. If not, you can proceed with confidence. 4. Remove tape gently: When removing the tape, do it slowly and at a low angle, preferably parallel to the surface. Pulling it too quickly or at a high angle can increase the chances of leaving behind sticky residue. Take your time and be patient to avoid any damage or residue. 5. Use heat or solvent if needed: In case some residue remains, you can try using gentle heat or certain solvents to remove it. For heat, you can use a hairdryer on low setting to warm up the residue and then wipe it away with a clean cloth. If needed, you can also try using rubbing alcohol, white vinegar, or adhesive remover by applying a small amount on a cloth and gently rubbing the residue until it dissolves. By following these tips, you should be able to prevent packaging tape from leaving a sticky residue and maintain a clean surface.

- Q: Is packaging tape safe to use on plastic outdoor furniture?

- Yes, packaging tape is safe to use on plastic outdoor furniture. It provides a secure and temporary solution for holding parts together or protecting certain areas during transportation or storage. However, it is important to note that the adhesive on the tape may leave residue on the furniture, especially if exposed to prolonged sunlight or extreme weather conditions. Therefore, it is recommended to remove the tape as soon as it is no longer needed to prevent any potential damage.

- Q: How does packaging tape compare to duct tape in terms of strength and durability?

- Packaging tape and duct tape differ in terms of strength and durability. While packaging tape is specifically designed for sealing and securing packages, it may not be as strong or durable as duct tape. Duct tape is known for its high strength and durability due to its reinforced backing material, making it ideal for a wide range of applications beyond packaging.

Send your message to us

Packaging Tape Ghost Directions Paper Masking Tape Manufactured in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords