Packaging PVC Film Manufacture/Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

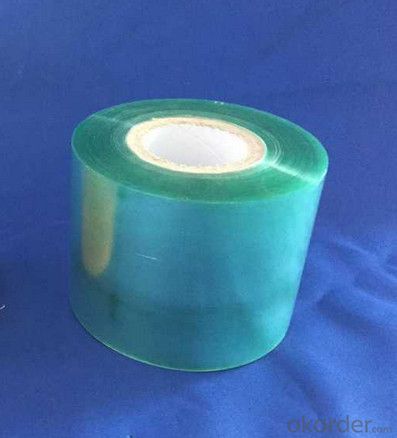

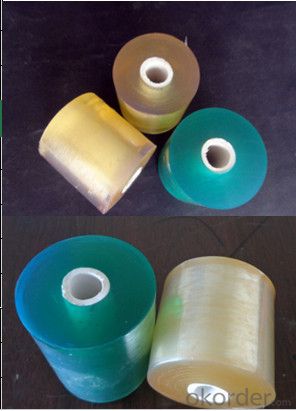

Pacakging PVC Film

Material: PVC

Thickness: 18-100 micron

Width: 10-150 mm

Color: transparent, green, yellow, and so on ( The film looks colorful, but when you pull it out you will find no color, totally transparent)

Application: widely used in electrical wires, cables,various steel, precision roller, hardware accessories, furniture, building decoration materials, tourism sneakers, etc.

Feature:

1. Excellent soft

2. Good tensile resistance

3. Without secondary pollution during usage

Item No, | Thickness micron | Total roll weight | Adhesion (N/cm) | Tensile strength (Kg/cm) | Elongation |

APF-20 | 20 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-40 | 40 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-60 | 60 | 250gram/ 70mm | 1.7 | ≥350

| ≥80%

|

APF-80 | 80 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

APF-100 | 100 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

- Q: What kind of material is plastic film in greenhouse?

- Polyethylene high foaming filmIt is a white, multi bubble plastic film. It is 1 meters wide and 0.4 to 0.5 centimeters thick. It is light enough to roll up, and its insulation is similar to that of grass.

- Q: What are the factors affecting the permeability of plastic film?

- Film properties. The permeability of polymer film is related to its structure. The permeability of polar film is larger than that of non-polar film, and the amorphous film is larger than crystalline film. In addition, the permeability coefficients of some polymer films are similar to those of saturated vapor pressure. The permeability coefficient of polyethylene and nylon films is several times higher than that of moisture permeability. This is mainly due to the formation of pores between crystals or grains, which facilitates the flow of liquid water.

- Q: Installation of air-conditioning machine inside the plastic film did not take off, the impact on the air-conditioning?

- General machine Binet machine should be low, even if not more than 2 meters high, if not otherwise back to normal compressor oil, long time will cause damage to compressor.

- Q: Plastic film sealing machine (Dorch) repair

- You, I have not seen this model, I do not know is semi-automatic film sealing machine, but also pedal, or hand press?. Pass the picture and see his structure.

- Q: What are the factors affecting the puncture strength of plastic film?

- The specific operation is as follows: the diameter of test piece 100mm is installed on the fixed clamping ring like membrane, with a diameter of 1.0mm spherical apex radius of 0.5mm needle, thorn to the top with the speed of 50mm/min, the maximum load test piece read needle penetration. I hope I can help you.

- Q: How to choose the plastic film for the salt packing bag?

- However, since it is a design competition, is it possible for you to design an internal and external package for the sale of edible salt? For example, are now promoting daily limit intake of salt, not excessive.

- Q: Why should a plastic film be affixed after the concrete has been poured?

- According to the actual situation at that time, if the temperature difference is greater than 25 degrees, should strengthen the insulation materials, such as covering rock wool, etc., in order to prevent concrete produce too large temperature difference, stress and cracks

- Q: Why should a plastic film be added to the new cement road?

- The maintenance of concrete, according to the thermal calculation, concrete internal and surface temperature is less than 25 degrees, concrete pouring time after surface covered with a layer of plastic film insulation, timely prevent the conservation of water caused by excessive temperature difference between inside and outside the concrete temperature crack.

- Q: What solvent can be used to remove the plastic film glued to the glass?

- You can remove nitro thinner scrub.Nitro thinner is used in automobile paint lacquer, the car paint, and then use the nitro thinner cleaning spray gun. The diluent is allergic to the skin, after evaporation, skin itching feeling, also feel hot.

- Q: Plastic film surface corona treatment, the bigger the better?

- The surface tension requirement of the general printing processing film is 38 42dyn; the surface tension of the composite processing film is required to reach 42 -54dyn; the surface tension of the film processed by vacuum aluminizing is not less than 42 50dyn.

Send your message to us

Packaging PVC Film Manufacture/Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches