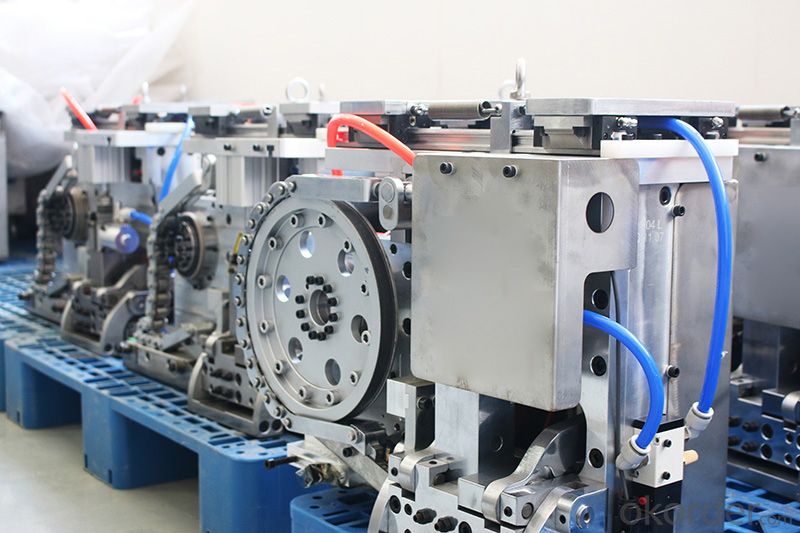

Packaging equipment---Digital intelligent baler head

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

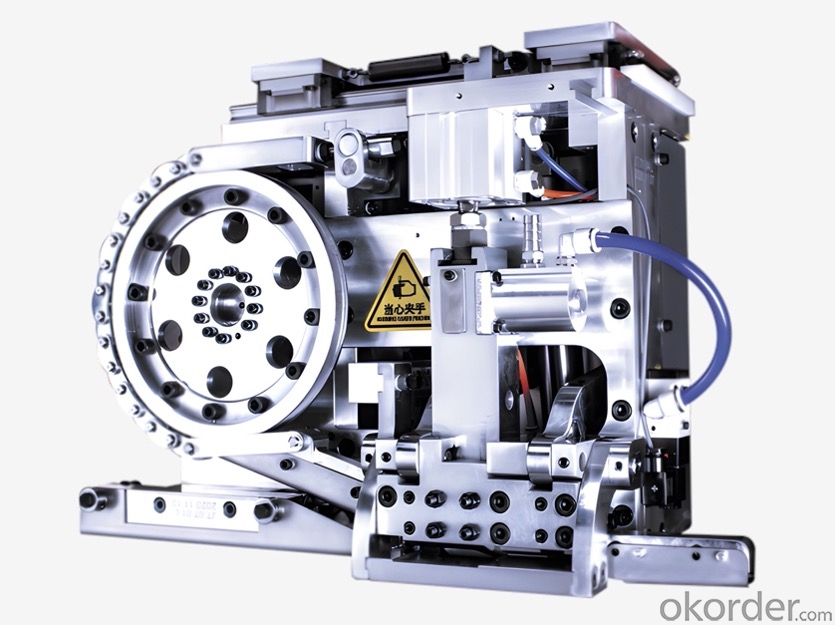

Product introduction:

The product is simple in structure, easy to maintain, and stable in performance. The tightening force can be adjusted arbitrarily by numerical control, and the maximum tightening force is 800kg.

1. Not easy to damage, low maintenance cost, remote maintenance

There are more than ten kinds of conventional wearing parts of imported machine heads. Our smart machine head has a reasonable structure and has abandoned some other redundant processes. There are only 4 conventional wearing parts, only the cutter, the friction bottom plate, and the friction machine. The head piece and the pulley, the maintenance cost is extremely low.

Adjustable tension, it can be tensioned multiple times without breaking.

2. Reasonable structure, quick maintenance, it only takes 10 minutes to replace any wearing parts

The disassembly process of the product is less than 3 minutes, and the installation of wearing parts is less than 3 minutes. The whole process only takes about 6 minutes. For other personnel, it will not exceed 10 minutes. This saves a lot of time and ensures the delivery of the project.

Finally, let's analyze the usage of this product.

1. The cost of machine head accessories can save 30,000-50,000 yuan per year.

2. Not easy to be damaged, save 30,000 yuan from belt wear and tear every year

3. The maintenance of other machine heads is delayed for a long time (1-3 hours), resulting in a decrease in output and an increase in various costs.

4.10 minutes quick maintenance without delaying production.

The overall cost saving is about 100,000 yuan a year.

- Q: What is the general packing cost of beer beverage packaging?

- A privately owned enterprise production and processing, wholesale distribution, production of various types of complete packing machine, sealing machine, packing machine, vacuum machine, sealing machine, electromagnetic machine, packing machine, mushrooms should be material, full automatic filling machine, cuff type packing machine, sending spot

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

- Q: What's the best place to use the pillow type packing machine?

- This device is now relatively mature technology, but each manufacturer's design is still a little different

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- You can send me a picture of your product and the process, so that I can answer your question exactly. More than 70% of the candies on the market are now automatically packed.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Energy saving reform of packaging machine

- First, the working principle of food packaging machinePillow type automatic packaging machine of the present domestic leading and most mature and reliable design and production technology, the essence of a collection of many years of experience in the field of packaging machinery, the packing machine can be used in a variety of composite packaging film coil on the packaging of bulk food, very suitable for the majority of users need to Chinese. 1) the electrical parts of the automatic packing machine are usually made up of the following parts:

Send your message to us

Packaging equipment---Digital intelligent baler head

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.