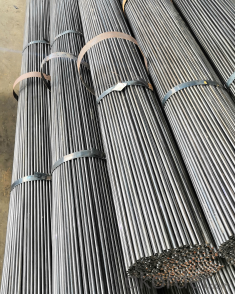

Oxygen cutting oxygen lance Metallurgical oxygen lance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Oxygen tube is used in steelmaking oxygen with small diameter steel pipe, small diameter welded steel pipe, is commonly used in standard by 3/8 inch - 2 inch eight, with 8, 10, 15, 20, or Q195 - made of Q235 steel strip. For corrosion protection, some aluminized processing.

Features:

decarburization

Carbon and other chemical composition to impart specific properties of metal or performance, therefore in the process of smelting should be carefully measure and control the chemical composition. Oxygen tube used in blast furnace, converter, induction furnace and electric arc furnace steelmaking decarburization is used, the rich oxygen mixture by oxygen tube into the molten metal. Oxidation of the metal liquid and excessive carbon, burn to the composition of its carbon down to the appropriate standards.

Open hole

When molten steel composition and temperature of the desired, using oxygen blowing tube open hole by means of drilling and tapping. Oxygen tube end connected to the hyperbaric oxygen, lit the end of the oxygen tube, through careful skilled operation, can make the thickness of 800 mm hole stemming burn out, help to metal flow of the molten liquid.

Clearing the ladle

After the casting process, the ladle block needs to clean up immediately. On the ladle slag must be cleaned up. Oxygen tube is used to clean up and down tube, such as there is embedded at the bottom of the ladle slag, also need oxygen tube to clean up.

Clean up the tundish nozzle

Tundish is temporary storage in the process of steelmaking metal liquid and the container. Compared with the oxygen tube cleaning tundish nozzle is more cost effective to replace the tundish nozzle system.

Clean up the slag skin

Oxygen tube can effectively clear cutting and slag layer caused by the slag skin, curing or solidification of metal and refractory insulation layer formation, reduce heat loss, protect the fusion line from corrosion and chemical attack and thermal shock.

The spillage clean molten steel

Oxygen tube used in the solidification of liquid steel spill split into small, is easy to deal with and help some valuable spills to melt or processing.

- Q: How are steel pipes used in the construction of dams and water reservoirs?

- Steel pipes are used in the construction of dams and water reservoirs primarily for their strength and durability. They are commonly used to transport water within the dam or reservoir, as well as for drainage systems. Steel pipes are also utilized for the construction of intake and outlet structures, penstocks, and other components that require a robust and reliable material to withstand the high pressure and heavy loads associated with dam operation.

- Q: How do you determine the required support spacing for steel pipes?

- Various factors, including the diameter of the pipe, the strength of the material, the operating conditions, and local building codes and regulations, determine the required support spacing for steel pipes. When considering the diameter of the pipe, it is crucial to note that larger pipes generally need more frequent support to prevent excessive deflection and sagging compared to smaller pipes. The strength of the material is also a significant consideration, as pipes with greater strength can span longer distances without requiring additional support. The operating conditions of the pipe, such as the type of fluid being transported and the temperature, also play a role in determining the necessary support spacing. For instance, pipes carrying heavy or corrosive fluids may require more frequent support to prevent excessive stress and potential failure. Local building codes and regulations often provide specific guidelines for the minimum support spacing of steel pipes. These regulations take into account factors such as the diameter of the pipe, the strength of the material, the operating conditions, as well as safety and structural requirements. To accurately determine the required support spacing for steel pipes, it is essential to consult relevant codes, standards, and engineering guidelines. Additionally, working with qualified engineers and professionals experienced in pipe design and installation will ensure that the support spacing meets all necessary requirements, ensuring the safe and efficient operation of the piping system.

- Q: How do you prevent freezing in steel pipes during cold weather?

- One effective way to prevent freezing in steel pipes during cold weather is to insulate the pipes. This can be done by applying foam insulation sleeves or wraps around the pipes. Additionally, ensuring that the pipes are properly sealed and any gaps or cracks are sealed can help prevent cold air from reaching the pipes. It is also important to keep the pipes warm by maintaining a consistent temperature in the surrounding area. This can be achieved by using a space heater or by allowing warm air to circulate around the pipes.

- Q: How are steel pipes used in the automotive industry?

- Steel pipes are commonly used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and resistance to high temperatures, making them ideal for carrying exhaust gases, fuel, and providing support to the vehicle's frame.

- Q: How do steel pipes compare to other types of piping materials?

- Steel pipes are widely considered to be one of the most durable and strong types of piping materials available. They offer superior strength, resistance to corrosion, and can withstand high pressure and extreme temperatures. Compared to other materials such as PVC or copper, steel pipes have a longer lifespan and are more suitable for heavy-duty applications. Additionally, steel pipes are highly recyclable, making them an environmentally friendly choice.

- Q: How are steel pipes used in the manufacturing of furniture and appliances?

- Steel pipes are commonly used in the manufacturing of furniture and appliances for various purposes. They are used as structural components to provide stability and support, especially in items like chairs, tables, and bed frames. Steel pipes are also used as frames or frames within frames for cabinets, shelves, and storage units, offering durability and strength to hold heavy objects. Additionally, steel pipes can be used as handles or legs for appliances, ensuring stability and easy mobility. Overall, steel pipes play a crucial role in enhancing the strength, stability, and functionality of furniture and appliances in the manufacturing process.

- Q: How do you calculate the deflection of a steel pipe?

- To calculate the deflection of a steel pipe, you need to consider various factors such as the material properties, applied loads, and geometrical characteristics. The following steps can guide you through the process: 1. Determine the material properties: Obtain the necessary information about the steel pipe, such as its Young's modulus (E), which represents its stiffness or resistance to deformation. This value is typically provided by the manufacturer or can be found in material databases. 2. Analyze the applied loads: Identify the types and magnitudes of the loads acting on the steel pipe. These loads can include point loads, distributed loads, or a combination of both. Determine the location and orientation of the applied loads as well. 3. Evaluate the pipe's geometry: Measure or obtain the dimensions of the steel pipe, including its length (L), outer diameter (D), and wall thickness (t). Ensure that these values are accurate to achieve a precise calculation. 4. Select an appropriate calculation method: Depending on the complexity of the loading and support conditions, you may need to use either simple beam theory or more advanced structural analysis methods, such as the finite element method (FEM). 5. Apply the appropriate equations: For simple beam theory, you can use the Euler-Bernoulli beam equation to calculate the deflection at a specific point on the pipe. This equation is based on assumptions that the pipe is homogeneous, linearly elastic, and subjected to small deflections. For more complex scenarios, FEM software can handle the calculations. 6. Determine the boundary conditions: Identify the support conditions at both ends of the pipe, which can include fixed supports, simply supported ends, or combinations of both. These conditions significantly affect the pipe's deflection. 7. Calculate the deflection: Using the equations relevant to your chosen method and incorporating the material properties, applied loads, and geometry, you can calculate the deflection at specific points along the steel pipe. The deflection can be measured in terms of vertical displacement or angular rotation. It is important to note that calculating the deflection of a steel pipe may require specialized engineering knowledge and software tools. If you lack experience in structural analysis, it is advisable to consult a professional engineer to ensure accurate results and safe design.

- Q: What are the different grades of steel used in pipe manufacturing?

- There are various grades of steel used in pipe manufacturing, including carbon steel, alloy steel, stainless steel, and duplex steel.

- Q: What are the different types of steel pipe supports for seismic applications?

- Some of the different types of steel pipe supports for seismic applications include sway braces, rigid braces, snubbers, and spring hangers.

- Q: What are the factors to consider when selecting a steel pipe for a specific application?

- When selecting a steel pipe for a specific application, there are several factors that need to be considered. These factors include the required strength and durability, the intended use and environment, the size and dimensions needed, the corrosion resistance properties required, the temperature and pressure conditions, and the budget available for the project. By taking all these factors into account, one can choose the most suitable steel pipe that meets the specific requirements of the application.

Send your message to us

Oxygen cutting oxygen lance Metallurgical oxygen lance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords