Orange Packaging Tape with Masking Tape Temperature Resistance 60 - World Top 500 Enterprise

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

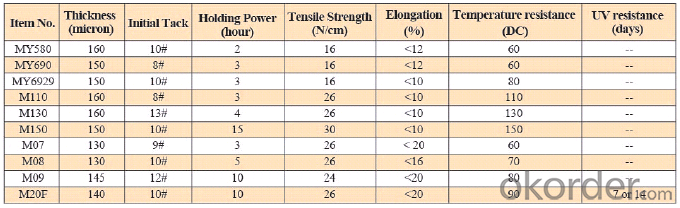

Typical Physical Reports of Masking Tape

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1800mm; width according to customers’ requirements

Cut Roll: As per customer’s requirements

Delivery Detail: within 10-12 working days after receiving your deposit

Service

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing electronic devices?

- Sealing electronic devices with packaging tape is not recommended. Although packaging tape is widely utilized to secure boxes and packages, it is not intended for sealing electronic devices. To ensure effective protection against moisture, dust, and other environmental factors, specific types of sealing materials are required for electronic devices. Relying on packaging tape may result in insufficient protection, which could potentially expose the electronic device to damage or malfunction. It is advisable to employ suitable sealing techniques and materials as recommended by the manufacturer or seek professional help when sealing electronic devices.

- Q: Are there any safety precautions to consider when using packaging tape?

- Yes, there are a few safety precautions to consider when using packaging tape. First, always use caution when handling the tape dispenser to avoid accidental cuts or injuries. Ensure that the area where you are using the tape is clear of any obstacles or potential tripping hazards. It is also important to store the tape in a safe place, away from heat sources or direct sunlight, as excessive heat can cause the tape to lose its adhesive properties. Lastly, be mindful of the weight and size of the package you are sealing, as using insufficient tape can cause the package to come apart during transportation.

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape typically struggles to perform well on surfaces that are oily or greasy. The adhesive on packaging tape is specifically designed to stick to surfaces that are clean and dry. Therefore, when applied to surfaces that are oily or greasy, the tape may have difficulty sticking securely. The presence of oil or grease acts as a barrier, preventing the adhesive from effectively bonding with the surface. Consequently, there is a greater likelihood of the tape peeling or coming loose. To ensure proper adhesion on surfaces that are oily or greasy, it is advisable to clean and degrease the surface thoroughly before applying packaging tape. Using a degreasing agent or detergent can assist in eliminating the oil or grease, thereby enabling the tape to adhere more effectively. In addition, opting for a high-quality packaging tape that possesses a strong adhesive can also help overcome the challenges posed by oily or greasy surfaces.

- Q: Does packaging tape come in different thicknesses?

- Yes, packaging tape does come in different thicknesses.

- Q: How do I prevent packaging tape from curling up?

- Here are some suggestions for preventing packaging tape from curling: 1. Opt for a tape dispenser: Employing a tape dispenser not only maintains the tape's straightness but also prevents it from curling. Moreover, it facilitates cutting the tape to the desired length. 2. Apply the tape evenly: While applying the tape, ensure to pull it tightly and evenly across the surface. Avoid any creases or air bubbles as they can cause the tape to curl. 3. Ensure surface cleanliness: Prior to applying the tape, guarantee that the surface is clean, devoid of dust, dirt, or moisture. These elements can interfere with the tape's adhesive properties and lead to curling. 4. Store the tape correctly: Proper storage of packaging tape is crucial for preventing curling. Keep it in a cool, dry place, away from direct sunlight. Drastic temperature fluctuations can impact the adhesive properties of the tape and result in curling. 5. Select high-quality tape: Invest in top-notch packaging tape specifically designed for long-term adhesion. Cheaper tapes often possess lower quality adhesives that are more prone to curling. 6. Utilize a heat source: If you encounter curling issues with the tape, you can attempt using a heat source, such as a hairdryer on a low setting. Gently warm the tape while applying it to activate the adhesive and minimize curling. By adhering to these suggestions, you can successfully prevent packaging tape from curling and achieve a secure and professional packaging appearance.

- Q: Can packaging tape be used for sealing plastic containers?

- Indeed, plastic containers can be securely sealed with the utilization of packaging tape. Specially designed to adhere to diverse surfaces, packaging tape effectively prevents spillage or damage to the container's contents. While commonly employed for sealing boxes in transit or storage, it can also be employed with efficacy on plastic containers. Nevertheless, it is crucial to ensure the tape is firmly affixed and all edges and seams are adequately sealed to uphold the container's integrity.

- Q: Is packaging tape compatible with automatic packaging machines?

- Yes, packaging tape is compatible with automatic packaging machines. Automatic packaging machines are designed to work with various types of packaging materials, including packaging tape. These machines are equipped with mechanisms to dispense and apply packaging tape efficiently and securely to seal packages. Packaging tape is often used in conjunction with automatic packaging machines to streamline the packaging process and ensure that packages are properly sealed and protected during transportation.

- Q: How do I remove packaging tape residue?

- To remove packaging tape residue, you can start by applying a small amount of oil or rubbing alcohol to a cloth or sponge and gently rubbing the affected area. This should help loosen the adhesive. Alternatively, you can also try using a mixture of warm water and dish soap, or a commercial adhesive remover. Make sure to test any method on a small, inconspicuous area first to ensure it doesn't damage the surface.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Yes, packaging tape can be used for sealing packages containing medical or pharmaceutical products. However, it is important to ensure that the packaging tape used is of high quality and specifically designed for such sensitive products to maintain their integrity and prevent any contamination.

- Q: Can packaging tape be used for sealing plastic lunch boxes?

- Indeed, plastic lunch boxes can be sealed using packaging tape. This type of tape is crafted to possess formidable strength and adhesive capabilities, rendering it appropriate for sealing a wide array of materials, plastic included. Its capacity to provide a secure seal ensures that the contents of the lunch box remain fresh and safeguarded. Nevertheless, it is crucial to acknowledge that using packaging tape on plastic lunch boxes may result in residue or surface damage upon removal. To avoid such complications, it is advisable to employ tape specifically engineered for sealing food containers or explore alternative methods such as rubber bands or clips, which are designed to secure plastic lunch boxes without causing any harm.

Send your message to us

Orange Packaging Tape with Masking Tape Temperature Resistance 60 - World Top 500 Enterprise

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords