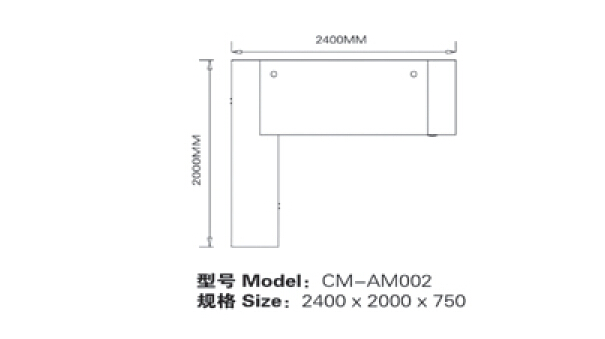

Office Table/ Excutive Desk Modern Wooden MDF Melamine/Glass Modular AM002

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Type: | Office Furniture | Specific Use: | Office Table | Wood Style: | Metal,MDF,Melamine |

| Certification | ISO9001 Quality & Enviroment | Size | 2800*1200*1100 | Advantages | Attractive Design ,Competitive Price |

| Assembling Guide | Available | customization: | Yes | Specific Uses | Office Desk ,Executive Desk |

| MOQ | 5 sets | Payment Term | T/T,L/C | Delivery Time | 15-20 days |

We specialized in office desk and office seating .Our factory has been engaged in office furniture for more than 10 years. Our factory is well-known in the high quality and competitive price of our products. Therefore, we completed in specifications and win warm praise from customers. In addition, the design of our products is deft, modern and beautiful. There are many types and colors for your selection. Our goods are easy and simple to handle and durable in use.

Welcome any questions!

- Q: What kind of glue does plywood use now?

- Depending on the composition of the gum, the glue used for building plywood is as follows:Urea formaldehyde adhesive: moisture-proof glue / for interior decoration, furniture, not for outdoor use.Melamine glue: moisture resistant, and has a certain water resistance and climate resistance / can be used outdoors or indoors, but not often immersed in water.Phenolic glue: moisture proof, excellent water boiling resistance and climate resistance characteristics can be used for outdoor or indoor / outdoor, can withstand exposed to wind and rain.

- Q: Why is there a difference in the price of roller wrapped rubber and wear-resistant diamond plywood?

- In addition to these two, there are many factorsFor example, we usually use a kind of rubber board, RIT roller wrapped rubber, wear-resistant diamond adhesive, with blue CN adhesive layer, paste without grinding treatment. Can be directly paste, and domestic production of rubber board, you need to be polished before you can.

- Q: Which is good, Take Sakaki template?

- Strength: bamboo plywood with bamboo polishing sheet, and woven bamboo, short and long curtain curtain, in the template group embryo, with long and short curtain curtain Jingwei staggered, and then combined with high temperature and high pressure, high strength; wood template is pine bark and eucalyptus veneer layers of glue after the first cold pressing and hot pressing molding, two;

- Q: What is the difference between building formwork and bamboo plywood?

- Toughness: the toughness of bamboo plywood is better;Number of times: ordinary bamboo plywood used 8 times, the building template in 6 times;Habits: the South with more building templates, the north with more bamboo plywood.

- Q: What's the difference between plywood and fiberboard?

- Plywood is to cut wood into thin sheets. After drying, some sheets of adhesive are bonded with adhesive and pressed and heated

- Q: What are the methods of fixing plywood?

- Slotting with biscuit, tenon and tenonLong term must use glue plus auxiliary fixed, short term use a kind of can.

- Q: What is an offset press? And what are the machines for printing paper?

- Offset printing press (offset press) is a lithographic printing machine, printing, printing graphics and printing from the printing plate first to the rubber cylinder, and then transferred to the paper by the rubber roller.

- Q: What is the density of the oil resistant rubber sheet?

- This problem no one can answer you, there are many kinds of oil resistant rubber, nitrile rubber, chloroprene rubber, acrylic rubber, fluorine rubber, different kinds of density vary greatly, even with a rubber formula, different density are also different

- Q: Is the wardrobe made of rubber strong?

- Plywood is one of the commonly used furniture materials. It is one of the three boards of wood-based panels. It can also be used as materials for aircraft, ships, trains, automobiles, buildings and packing boxes. A set of veneers usually glued together in a direction perpendicular to the direction of the adjacent layers of wood. Usually the table plate and the inner plate are symmetrically arranged on both sides of the central layer or the core of the plate. A single slab made of glued sheets that are Criss crossed in the direction of wood grain. The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three common types of plywood plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood.

- Q: Plywood (multi layer), this side of the small hole is what happened, please answer in detail!

- This is the result of the three combinations of materials, processes, and equipment.First of all, the materials used are not good materials, most of which are made of many kinds of timber, and the texture is hard and soft. Secondly, there is also the problem of the quality of adhesive used, adhesion or poor sizing, sizing or uneven and so can not be effectively bonded, so at the time of cutting the structure loose and crack. Third, mechanical equipment problems.In short, a good material + reasonable process + advanced equipment, in order to produce good products

Send your message to us

Office Table/ Excutive Desk Modern Wooden MDF Melamine/Glass Modular AM002

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords