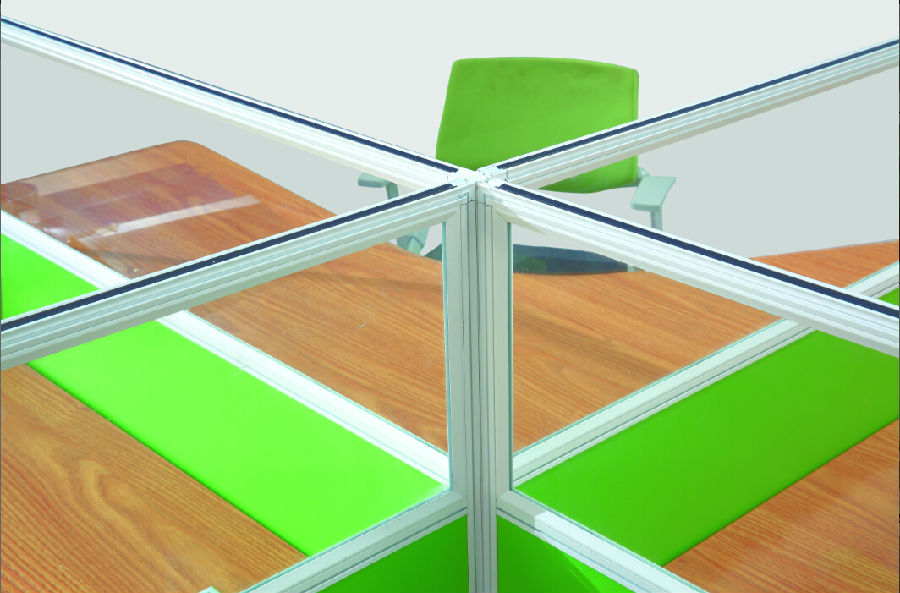

Office Table/Desk Hight Quality Wood MDF Melamine/Glass CN688 S

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Type: | Office Furniture | Specific Use: | Office Table | Wood Style: | Metal,MDF,Melamine |

| Certification | ISO9001 Quality & Enviroment | Size | 2800*2800*1050 | Advantages | Attractive Design ,Competitive Price |

| Assembling Guide | Available | customization: | Yes | Specific Uses | Office Desk ,Executive Desk |

| MOQ | 5 sets | Payment Term | T/T,L/C | Delivery Time | 15-20 days |

We specialized in office desk and office seating .Our factory has been engaged in office furniture for more than 10 years. Our factory is well-known in the high quality and competitive price of our products. Therefore, we completed in specifications and win warm praise from customers. In addition, the design of our products is deft, modern and beautiful. There are many types and colors for your selection. Our goods are easy and simple to handle and durable in use.

Welcome any questions!

- Q: What is the difference between laminated lumber (LVL) and plywood (plywood)?

- Plywood PLYWOOD, usually refers to the adjacent layer of wood fiber in the way of crossing, in order to tension is even.

- Q: And as you kt PVC board

- PVC board is made of PVC as the raw material, and the section is honeycomb like mesh structure.

- Q: What is the use of plywood in decoration engineering?

- Plywood is one of the commonly used furniture materials. It is one of the three boards of wood-based panels. It can also be used as materials for aircraft, ships, trains, automobiles, buildings and packing boxes. A set of veneers usually glued together in a direction perpendicular to the direction of the adjacent layers of wood. Usually the table plate and the inner plate are symmetrically arranged on both sides of the central layer or the core of the plate. A single slab made of glued sheets that are Criss crossed in the direction of wood grain. The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three common types of plywood plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood.

- Q: What are the specifications of plywood?

- The classification of many kinds of plywood, plywood by species can be divided into softwood and hardwood plywood plywood; use can be divided into ordinary plywood, plywood, cement formwork structure plywood, fireproof plywood and special plywood etc..

- Q: The difference between a plywood, a plywood, and a cover plate

- A building block is a variety of plywood classified according to usage, used for concrete construction, and is a kind of plywood.Most of the building blocks are made of plywood.

- Q: How to distinguish between good and bad construction wood board?

- Same specification1. look at raw materials. The raw material monoliths and scrap.2. glue. Phenolic resin. Three amine gel. Glue (glue urine)The simplest test: take a 10cm*10cm sample and cook it. It is easy to open plastic goods (less than 30 minutes)Boil for 1 hours.Boil for more than 3 hours, even if the good

- Q: The difference between wood cored plywood

- Different material: wood core plate (Blockboard): the main material is the core of small pieces of wood mosaic, surface veneer and veneer; MDF: material for wood fiber and wood powder after crushing; plywood (also called splint

- Q: What is copper paper or rubber paper?

- Coated paper is also called coated printing paper. It is called "powder paper" in areas such as Hongkong. It is an advanced printing paper made of base paper coated with white paint. Mainly used for printing books cover and illustrations, senior color pictures, a variety of exquisite product advertising, packaging, trademarks, sample.Art paper is flat paper, the size is 787 * 1092mm, 880 * 1230mm, the quantitative is 70 ~ 250g/m? 2. Coated paper has a single side coated paper, double-sided coated paper, matt coated paper, matte coated paper points. According to the quality is divided into A, B, C three, etc.. The main raw material of art paper is copperplate base paper and coating. The requirements of the coated medium are uniform thickness, low elasticity, high strength and good water resistance. The paper no spots, wrinkles, eye disease and other paper, used for coating paint is made from white pigment quality (such as kaolin, barium sulfate, etc.), adhesive (such as polyvinyl alcohol, casein etc.) and auxiliary additives etc.. The high mobility and high solid content coatings, the coating machine is thin and evenly coated on the base paper, then dried, in rolls of paper machine roll drum shaped, and then sent to the super calender are discusses, finally cutting, paper selection, packing.

- Q: What is the density of the oil resistant rubber sheet?

- The best way is to take a sample test. Fluorine rubber biggest proportion, nitrile rubber minimum proportion, mixed rubber 1.0~1.2 between. Chloroprene rubber compound is around 1.3

- Q: What are the benefits of a plywood desk?

- The disadvantage is that it is too popular, and the more you use it, the more likely it is to devalue. Also, because of heavy and crisp plywood (mainly the glue itself heavy and brittle), its furniture screws, particularly by the connection of the regular activities of the loose leaf point tends to loose, so be sure to choose the regular manufacturers

Send your message to us

Office Table/Desk Hight Quality Wood MDF Melamine/Glass CN688 S

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches