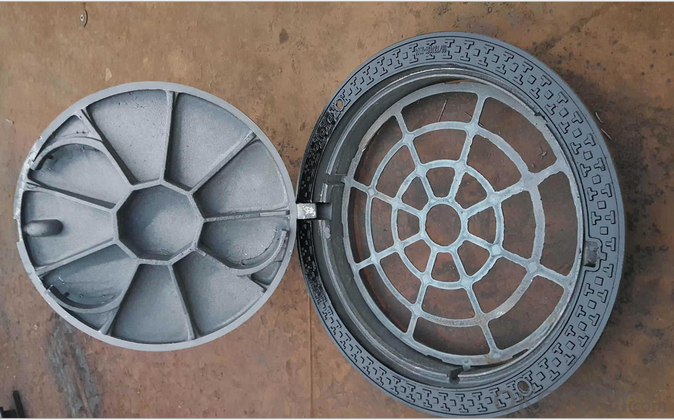

OEM 75 mm cast ductile iron manhole covers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or samples.

2) Color: black, Grey, green, blue and Marble , etc.

3) Applications: water supply and drainage, fire engineering, natural

4) Inspection: in-house or the third party as per customer's request.

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| D80 | D400 | 700*700 | 800*800 | 100 | 92 |

| D70 | D400 | 600*600 | 703*703 | 100 | 77 |

1. Light weight,Anti-corrosive

2. High pressure endurance

3. Easy to install and open

4. Long and steady service

Ductile Iron manhole cover & grating features:

1. High strength:The tensile strength of ductile iron is more than 420Mpa and the yield strength is more than 300MPa, three times more than gray iron.

2. Good toughness: impact value is similar to carbon steel and 10 times than grey iron.

3. Good plasticity. Elongation of ductile is more than 7% which is similar with high-carbon steel, gray iron material and extend rate is zero.

4. Anti-corrosion resistance: The corrosion was only 0.25 times of pipes during ninety days spray corrosion test and 0.1 times of gray iron pipes. The life is 2 times longer than gray iron pipes and 5 times longer than ordinary steel pipe.

5. Applied In most municipal applications: water, salt water, steam, the corrosion resistance and oxidation resistance of cast iron are more than steel. Because of the spherical graphite cast iron microstructure, ductile iron does better than steel in reduced vibration capacity.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- The pre treatment temperature and the quality of plastic powder are likely to be problems

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: The casting sand is going on

- 2, causes(1) sand mold (core) strength is not high, when the box a little reason will fall off.(2) the strength of sand mould (core) is not high, it can not stand the erosion of molten steel.(3) box sand mould (core) crush.(4) high strength under high temperature, warpage, deformation and protuberance into the cast steel under the action of high temperature molten steel.(5) the floating sand in the air hole of the sand mold falls, especially when the floating sand falls in the casting, and the floating sand on the surface of the sand mold is easy to fall through the air vent.(6) when the box is closed, the surface of the mold cavity and the surface of the sand core are not cleaned, and the sand (core) surface has floating sand and so on.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- There are several casesThe first hole with a diameter of less than 4MM is generally not done, or as a hole location only for a period of less than 10MM.Second for the big hole, some of the reasons for the holding force, we must increase the slope, direct tapping is unlikely, so it still needs post-processingThird for products with high tightness requirements, some cores need to be made even if they are very small, so they can be tapped directlyFourth, some due to technical requirements, regardless of the size of each other's requirements must be made, there is no wayThe above methods are common, and they will encounter many small problems in actual production.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: What is the difference between casting and stamping parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine,

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

Send your message to us

OEM 75 mm cast ductile iron manhole covers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches